smallpox structure

A technology for ceiling structures and ceilings, applied in building components, building structures, buildings, etc., can solve problems such as unfavorable maintenance and installation, high labor intensity, and time-consuming, and achieve convenient maintenance and replacement, and improve decoration efficiency. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

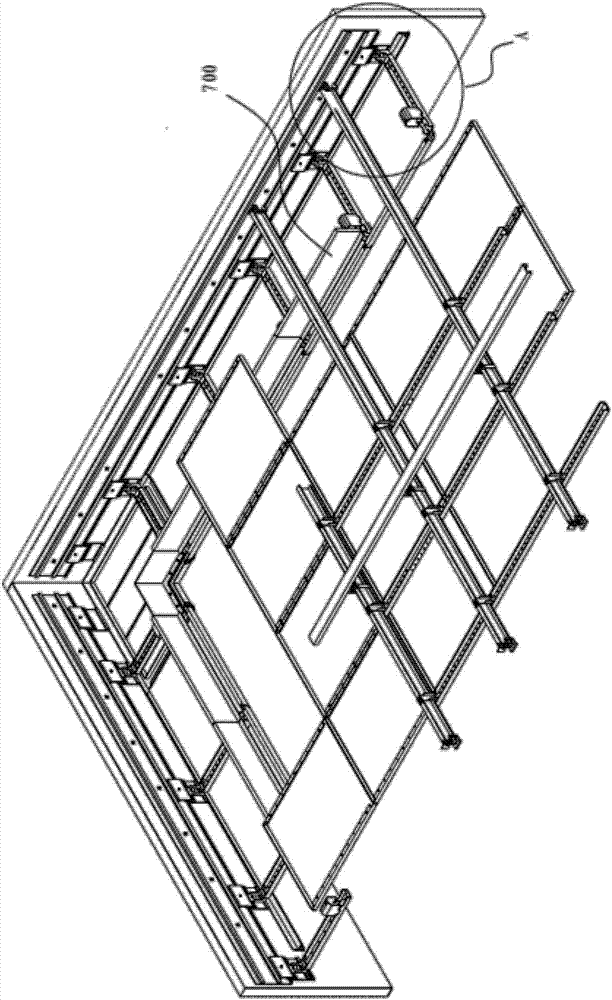

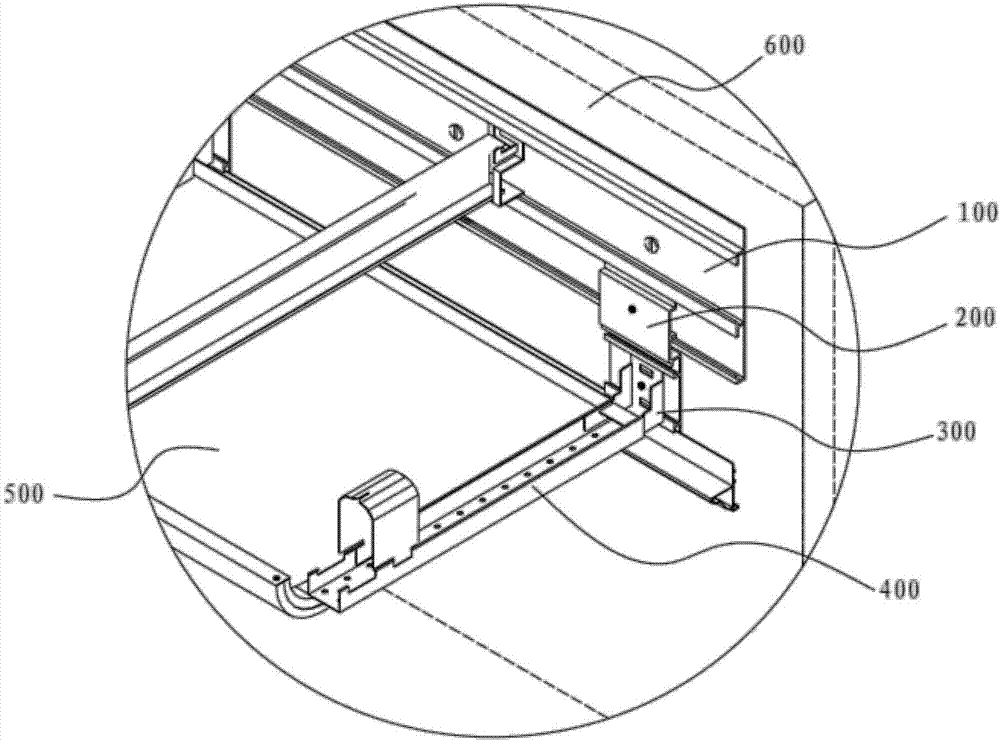

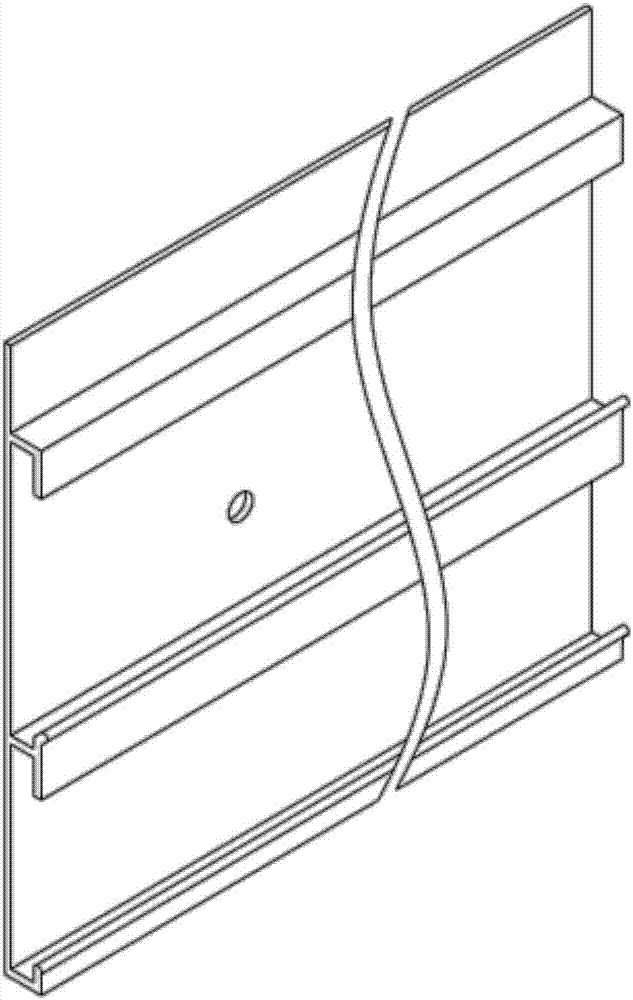

[0034] Ceiling structure, including: cantilever, ceiling 500, first ceiling, support beam 100.

[0035] The support beam 100 is fixed on the wall 600 or the roof. The support beam 100 is provided with a transverse slideway 120 and a first hook part 110. The first hook part 110 is located above the transverse slideway 120. The first ceiling includes a first keel 400 and the first ceiling 500, the first keel 400 is provided with a second buckle part, the first buckle part 110 is hooked to the second buckle part (the first buckle part 110 can also be a horizontal or nearly horizontal slideway, The first hook part 110 is slidably connected to the second hook part), and the first ceiling 500 is installed on the first keel 400 . (Or the first ceiling is the roof itself.)

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com