Volute-spraying type water turbine

The technology of one type of water turbine and volute spray is applied in the design and manufacture of water conservancy power generation equipment, which can solve the problems of poor output effect, long production cycle and maintenance cycle, and increased manufacturing cost, so as to achieve the effect of improving potential energy and improving output effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

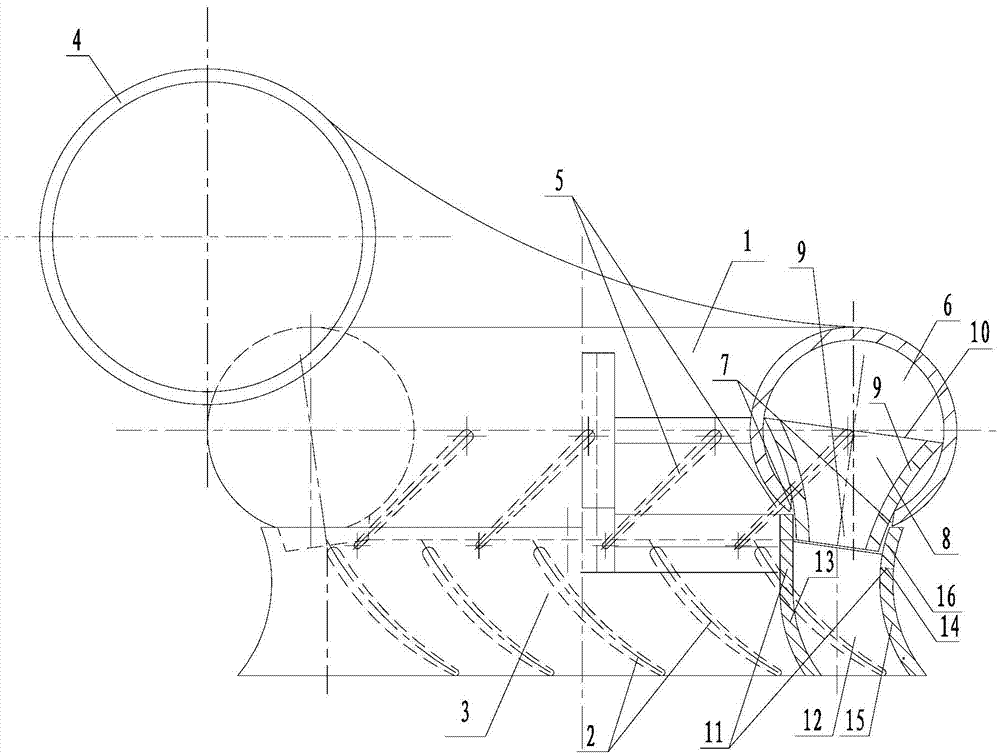

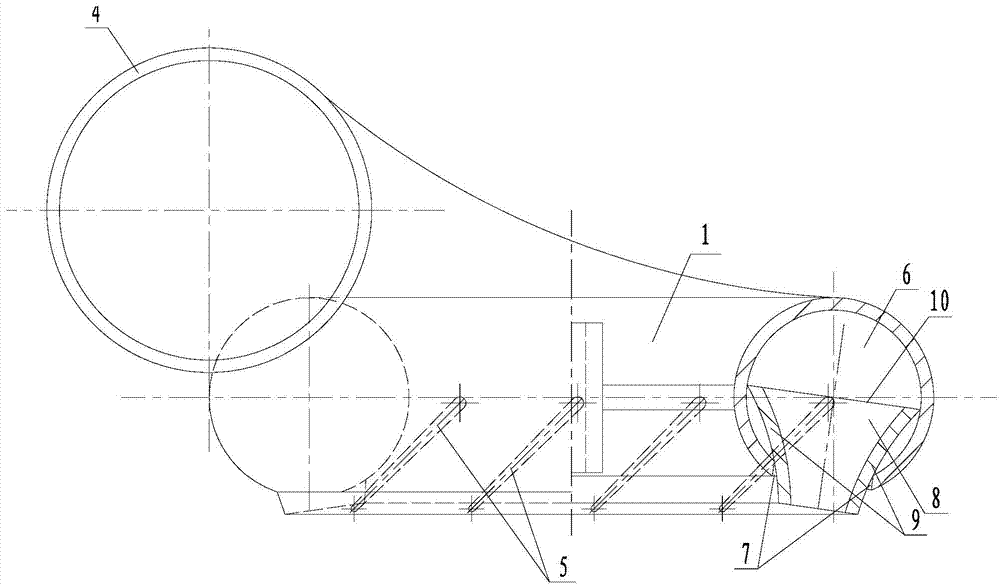

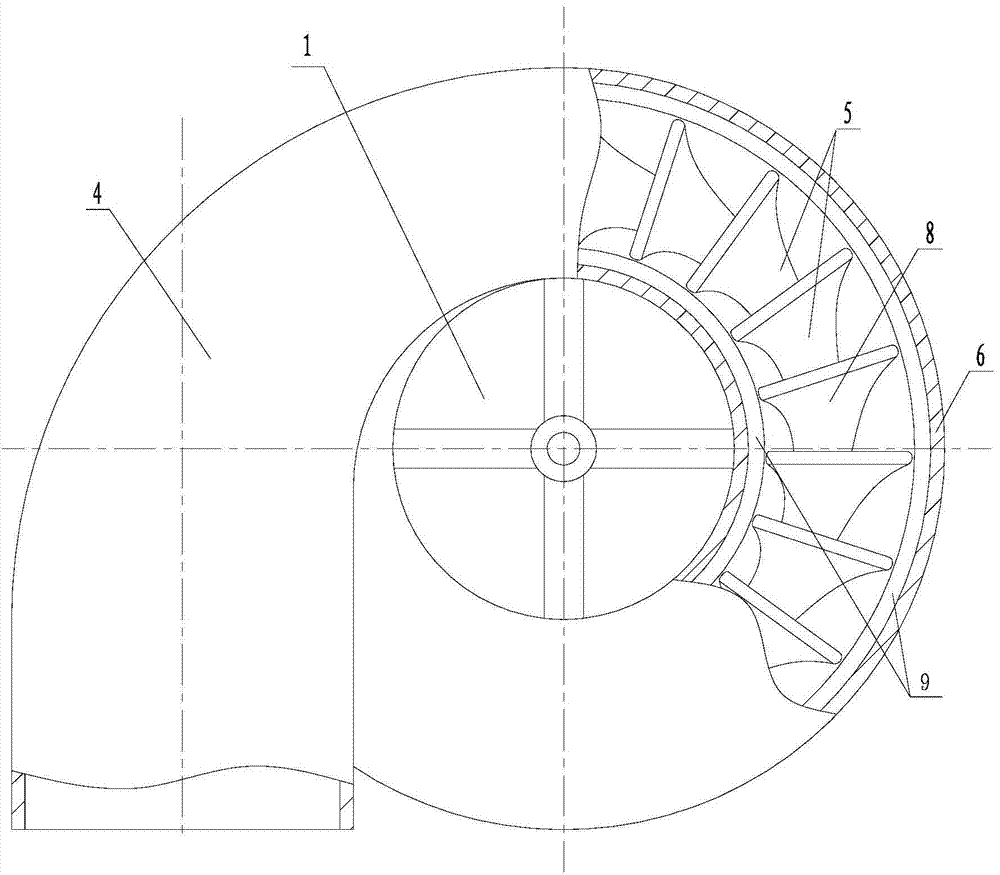

[0020] Such as figure 1 , figure 2 , image 3 as well as Figure 4 Shown is a kind of can significantly improve output effect that the present invention provides Worm Jet Turbine . said Worm Jet Turbine said Worm Jet Turbine It includes a guide water spray device 1 and a water diversion rotating device 3 containing a hydraulic drive mechanism 2, the guide water spray end of the guide water spray device 1 communicates with the driving water flow input end of the water diversion rotation device 3; Worm Jet Turbine During the working process, the power-driven water flow is input into the water diversion rotating device 3 through the described guiding water spraying device 1, and the generating driven water flow in the described water diverting rotating device 3 is input through the described guiding water spraying device 1, and passed through The hydraulic driving mechanism 2 is driven to drive the water diversion rotating device 3 to rotate around its own axial c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com