Electric conduction rail type mounting assembly

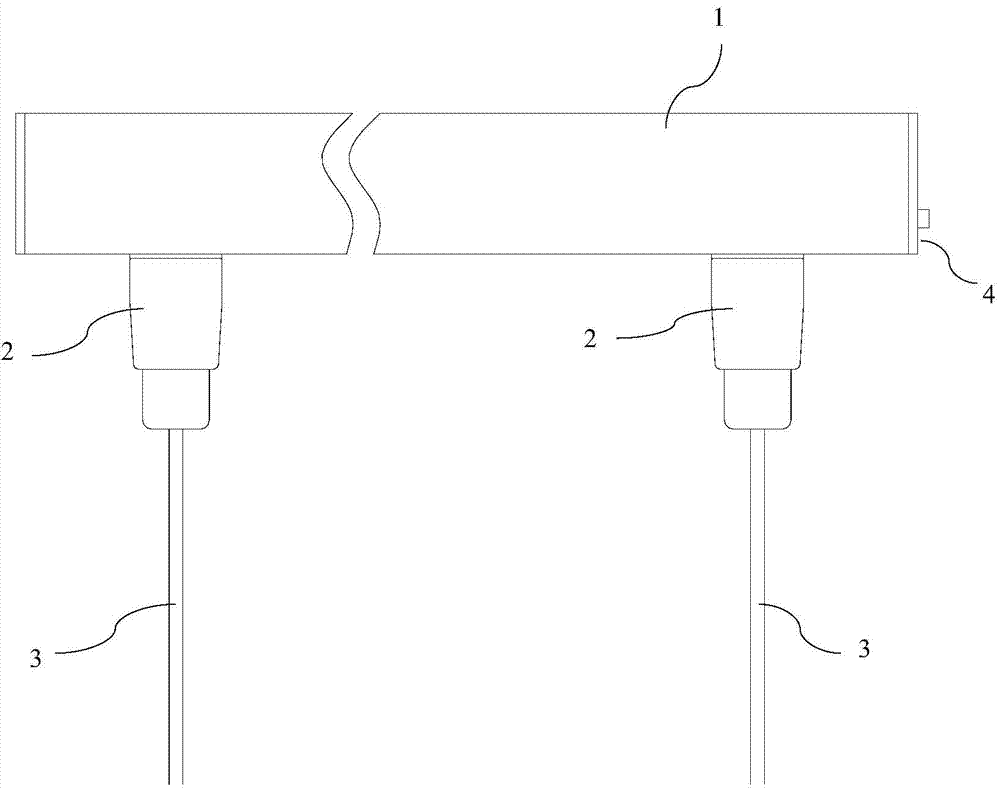

A technology for installing components and conductive tracks, which is applied to the components of lighting devices, lighting devices, circuit layout, etc., can solve the problems of long installation time, high installation cost, difficult to replace, etc., and achieves light and simple overall structure, manufacturing and installation. Low cost, clever setup and transition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] There is one suspension assembly 2, and a single suspension assembly 2 draws positive current and negative current respectively.

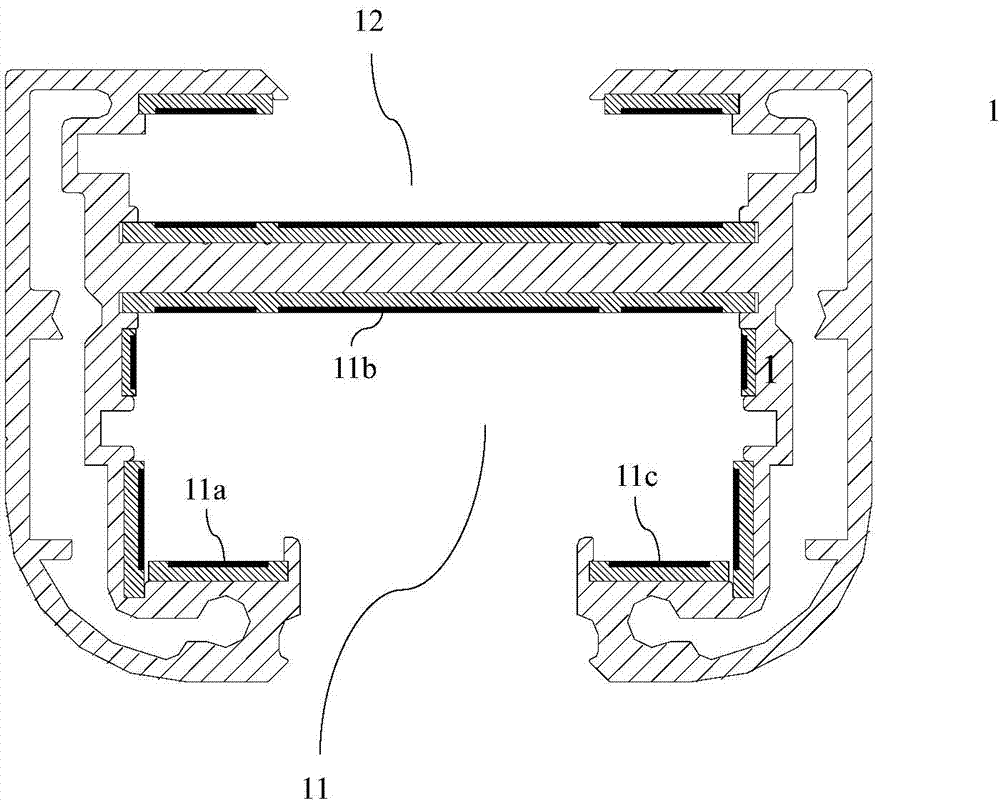

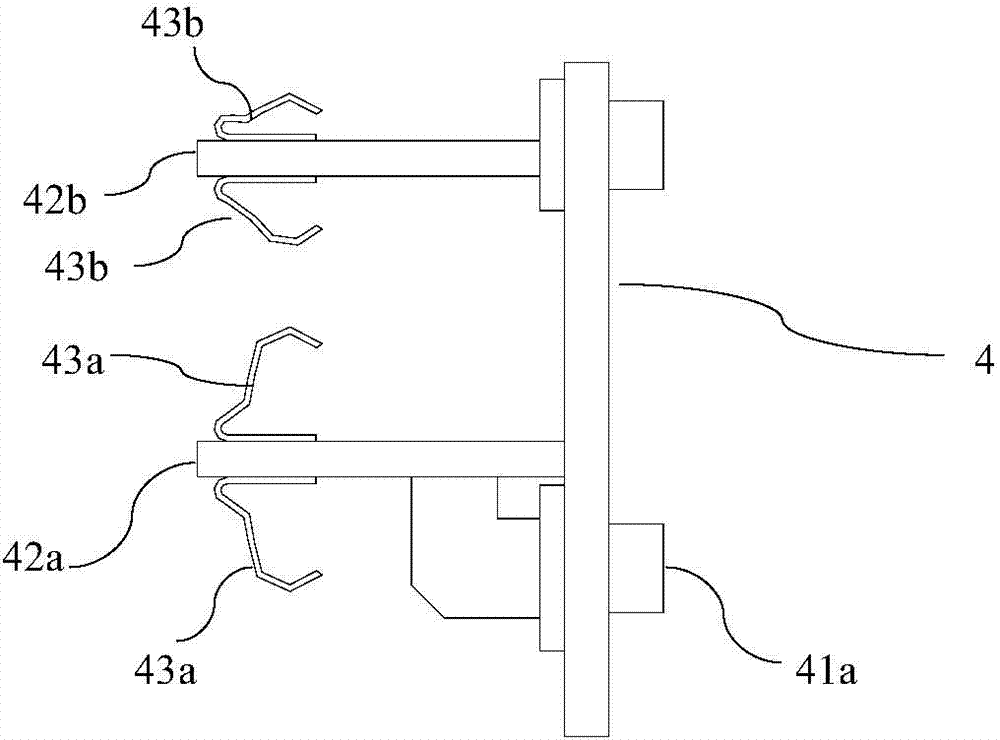

[0046] Specifically, as figure 2 As shown, the first electrode 11a is set on the left bottom wall in the first rail 11, the third electrode 11c is set on the right bottom wall, and the second electrode 11b is set on the top wall. Figure 5-6 The first flat-head screw 22a is the touch piece that conducts the first electrode 11a. Unscrew the first flat-head screw 22a and make contact with the first electrode 11a. The first through hole 230a of the first insulating rubber seat 23a is located in the second through hole. Below the hole 230b, the lowermost end of the first insulating rubber seat 23a abuts against the first flat head 220a of the first flat head screw 22a, so that the first flat head screw 22a is in stable contact with the first electrode 11a, and conducts the first electrode. 11a, and the first electrode current is passed to the ...

Embodiment 2

[0051] The difference from Embodiment 1 is that the first flat-head screw 22a is separated from the first electrode 11a, and the first electrode 11a is not connected. The specific structure is the same as that of the second flat-head screw 22b and the second glue seat 23b is the same; at the same time, the second flat-head screw 22a is in contact with the third electrode 11c, and conducts the current of the third electrode 11c. The grub screw 22b guides the current of the third electrode 11c to the conductive base 21, and then guides the current from the conductive base 21 to the conductive connecting pipe 26 as an external electrode; the same as the embodiment 1, the contact element in contact with the second electrode 11b is Sliding column 24, and sliding column 24 is the conductive column that is made of metal, then derives the second electrode current by conductive column, and the second electrode current is passed to wire 3, as external electrode, so the second electrode c...

Embodiment 3

[0055] The difference from Embodiment 1 is that, in addition to the first flat-head screw 22a being in contact with the first electrode 11a as a contact, the second flat-head screw 22b is also in contact with the third electrode 11c as a contact, and the second flat-head screw The contact structure of 22b is the same as that of the first flat-head screw 22a and the first insulating rubber seat 23a, the first electrode current derived from the first flat-head screw 22a and the second electrode current derived from the second flat-head screw 22b together serve as positive current, and are conducted to the conductive base 21, and then conducted to the conductive connecting pipe 26 by the conductive base 21 as an external electrode; the same as in Embodiment 1, the contact element in contact with the second electrode 11b is a sliding column 24, and the sliding column 24 If it is a conductive column made of metal, the second electrode current is derived from the conductive column as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com