Quick-response phase-change heat storage type heat exchanger

A phase-change heat storage and rapid response technology, applied in heat exchanger types, indirect heat exchangers, heat storage equipment, etc., can solve the difficulty of low-grade heat energy recovery, heat storage materials that do not meet the requirements of low-grade heat energy storage, Limit the research and development of fast-response regenerative heat exchangers to achieve the effect of solving discontinuous heat energy and simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

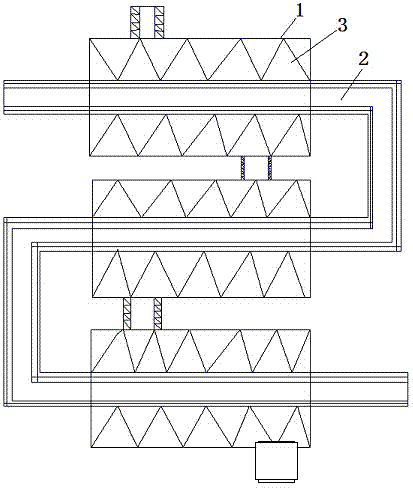

[0012] Such as figure 1 As shown, a fast-response phase-change heat storage heat exchanger includes an outer casing 1, an inner pipe 2, a phase-change capsule 3, a foam layer, and the like.

[0013] The phase change capsule 3 is filled between the outer casing 1 and the inner pipe 2, and absorbs the heat from the heat exchange fluid of the inner pipe through its phase change; the outer casing 1 is wrapped around the inner pipe 2 and the phase change capsule 3, and has an internal Pipeline inlets and inlets and outlets through which heated fluid flows.

[0014] The internal pipe 2 adopts a polished copper pipe surface, which not only resists the corrosion of common liquids, but also reduces the flow resistance of the fluid. The corner of the inner pipe is designed to be streamlined to minimize local resistance.

[0015] According to the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com