A detection method for strain-intensified non-uniform deformation of stainless steel welded joints

A detection method, strain strengthening technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of sample destruction, cumbersome handling, and difficulty in realizing the continuity of detection positions, etc., and achieve the effect of reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

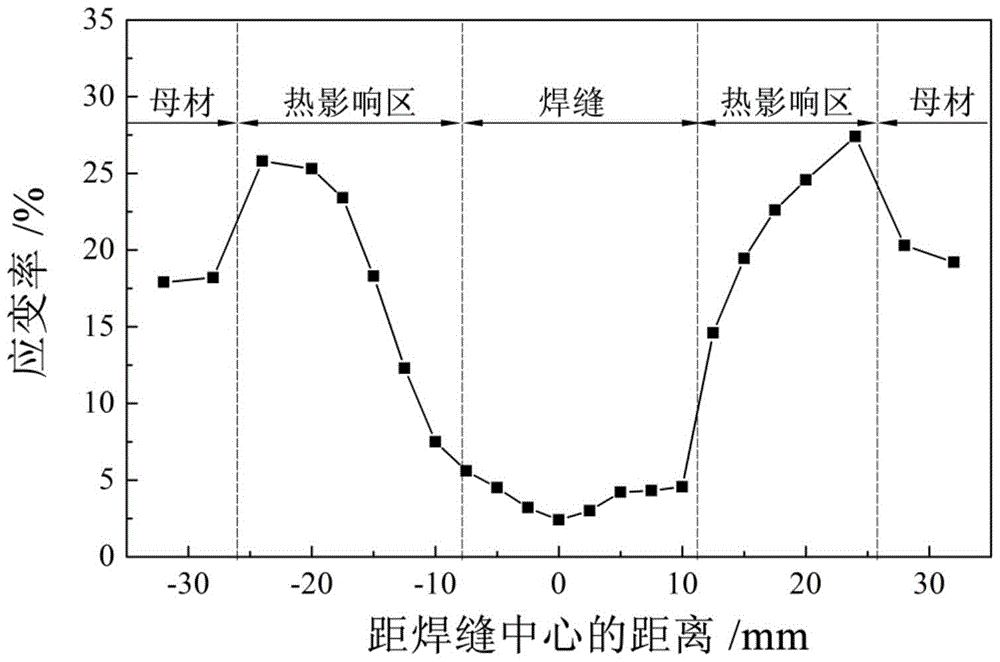

Embodiment 1

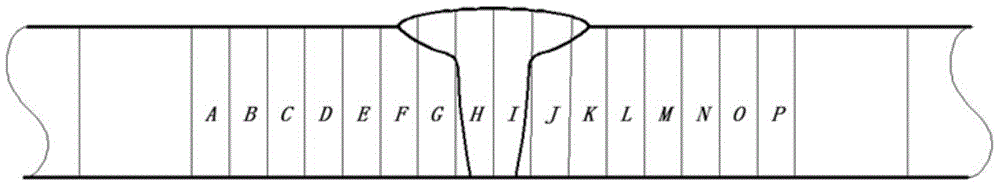

[0040] 304 austenitic stainless steel plate with a thickness of 10mm, the size of the test plate is 180mm×160mm×10mm, the test plate is welded by plasma arc welding, and its chemical composition is C 0.06%, Si 0.40%, Mn 1.62%, P 0.026%, S0.012%, Ni 8.14%, Cr 18.03%, Fe balance.

[0041] (1) Preparation before testing

[0042] Use a press to correct and level the deformation of the stainless steel test plate after welding, fix the weldment between the two supports, the back of the weld seam faces upward, and make the weld seam coincide with the centerline of the two supports, and then apply downward pressure on the weldment The pressure makes it produce plastic deformation opposite to the welding deformation, compensates the original welding deformation, and is beneficial to adjust the distribution of residual stress in the test plate and reduce the residual stress.

[0043] In order to prevent the structure and performance from being affected by the excessive temperature duri...

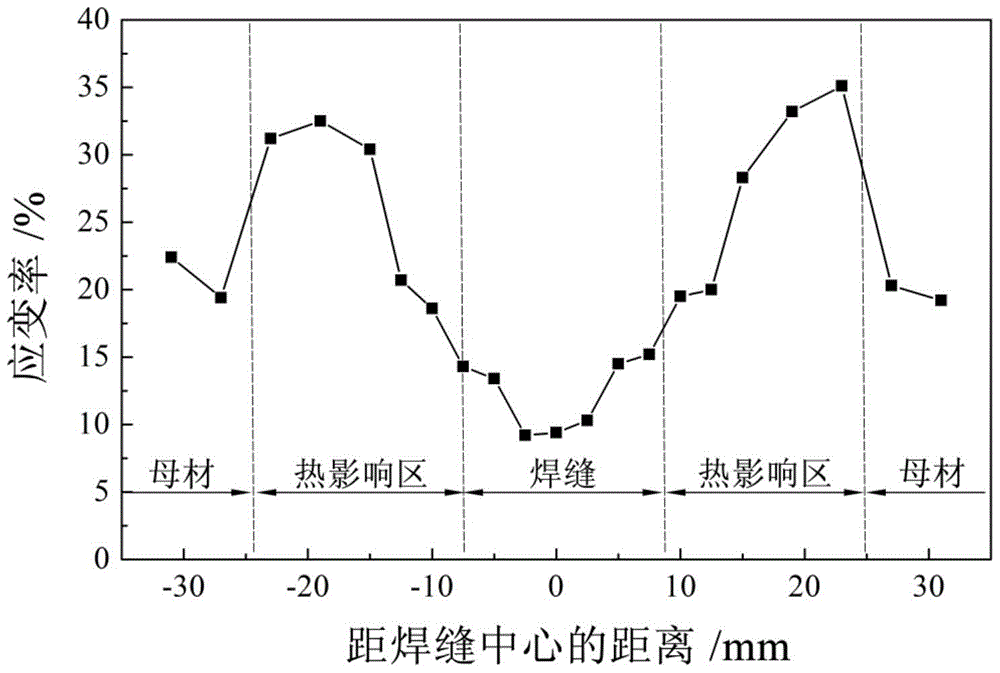

Embodiment 2

[0050] 304L stainless steel plate with a thickness of 12mm, the size of the test plate is 200mm×180mm×12mm, the test plate is welded by plasma arc welding + argon tungsten arc welding, and its chemical composition is C 0.02%, Si 0.50%, Mn 1.60%, P0.024%, S 0.014%, Ni 11.00%, Cr 19.80%, Fe balance.

[0051] (1) Preparation before testing

[0052] Use a press to correct and level the deformation of the stainless steel test plate after welding, fix the weldment between the two supports, the back of the weld seam faces upward, and make the weld seam coincide with the centerline of the two supports, and then apply downward pressure on the weldment The pressure makes it produce plastic deformation opposite to the welding deformation, compensates the original welding deformation, and is beneficial to adjust the distribution of residual stress in the test plate and reduce the residual stress.

[0053] In order to prevent the structure and performance from being affected by the excess...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com