A permanent magnet differential transmission mechanism

A differential transmission and permanent magnet technology, applied in the field of transmission mechanism and permanent magnet differential transmission mechanism, can solve the problems of being unsuitable for large-scale use, unable to change the transmission ratio, and high technical requirements, reducing the moving distance and saving permanent magnets , the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing of description, the present invention will be further described.

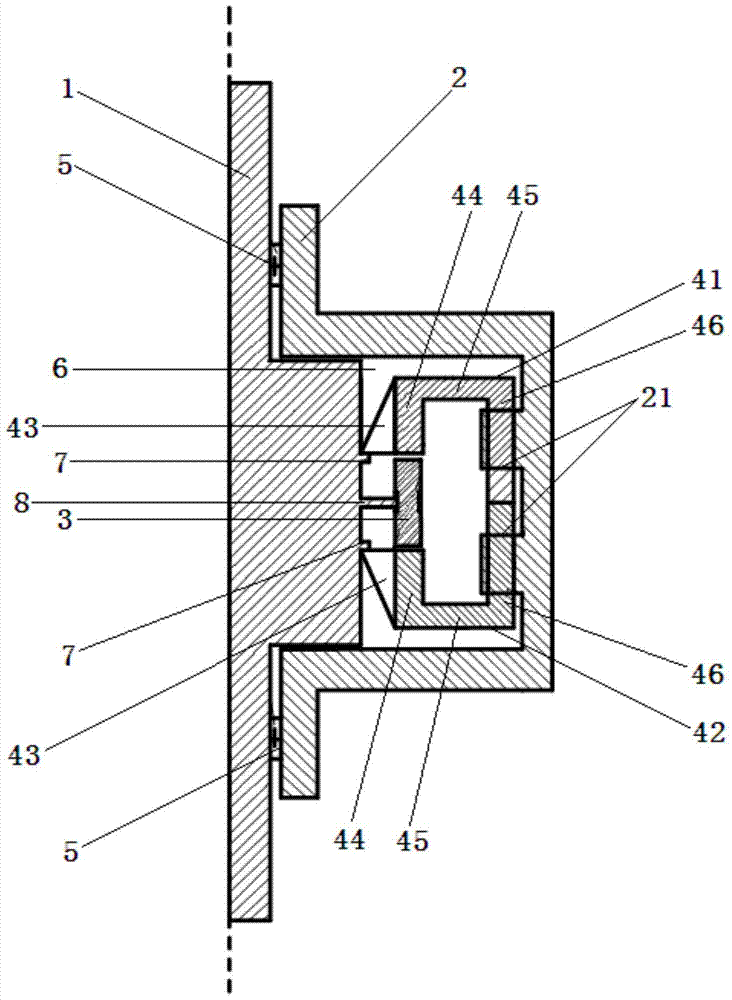

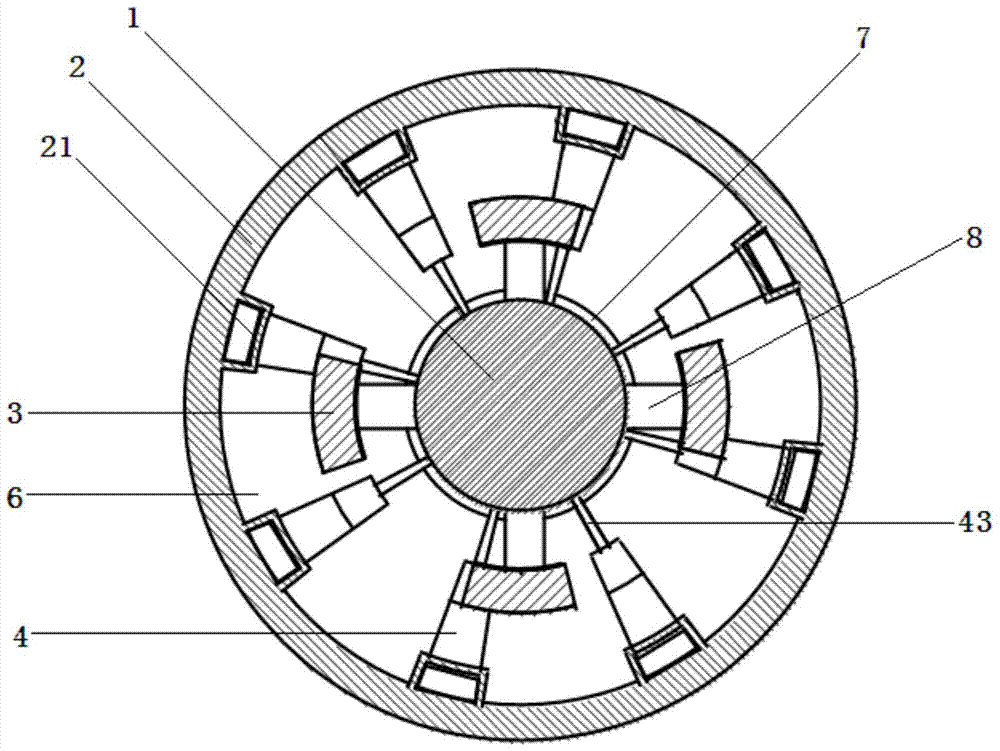

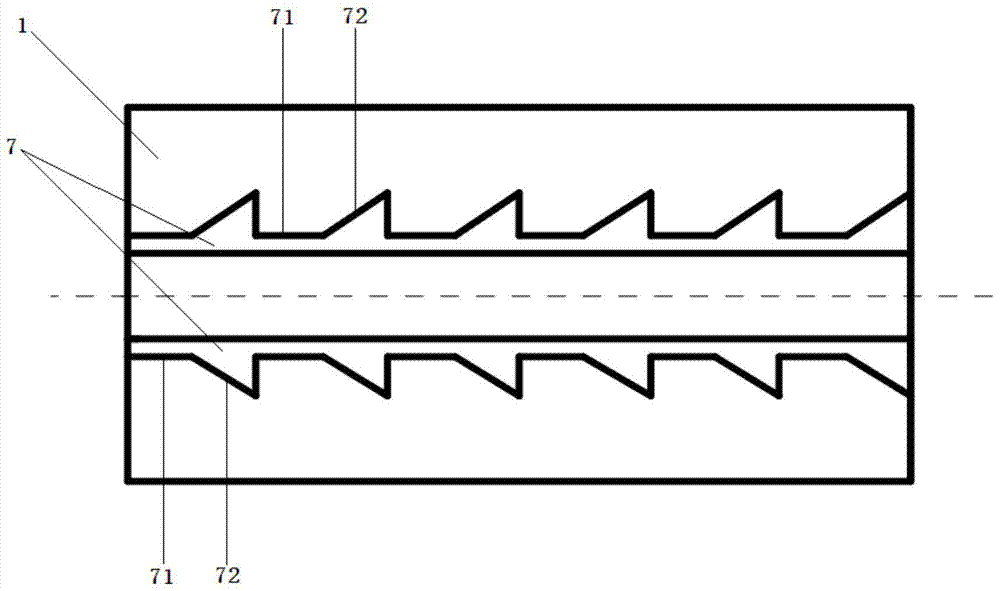

[0029] Such as figure 1 and figure 2 As shown, a permanent magnet differential transmission mechanism includes an inner shaft 1, an outer shaft 2, a permanent magnet rotor 3 and a magnetically permeable rotor 4. The magnetically permeable rotor 4 includes a first ferromagnetic block 41 and a second ferromagnetic block 41 arranged symmetrically. Two ferromagnetic blocks 42.

[0030] The inner shaft 1 is connected to the outer shaft 2 through a bearing 5, and an accommodating cavity 6 is provided between the inner shaft 1 and the outer shaft 2 for accommodating the permanent magnet rotor 3 and the magnetic permeable rotor 4; the permanent magnet rotor The quantity ratio of 3 and magnetic permeable rotor 4 is 1:2, and they are evenly spaced; the inner shaft 1 is connected to the permanent magnet rotor 3, and the circumferential surface of the inner shaft 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com