Method and device for calibrating mobile phone production test system

A test equipment and production test technology, applied in the field of communication, can solve the problems of high calibration cost, inability to calibrate the consistency of mobile phone comprehensive test instruments, and consumption of large test machines, etc., to achieve the effect of rapid measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

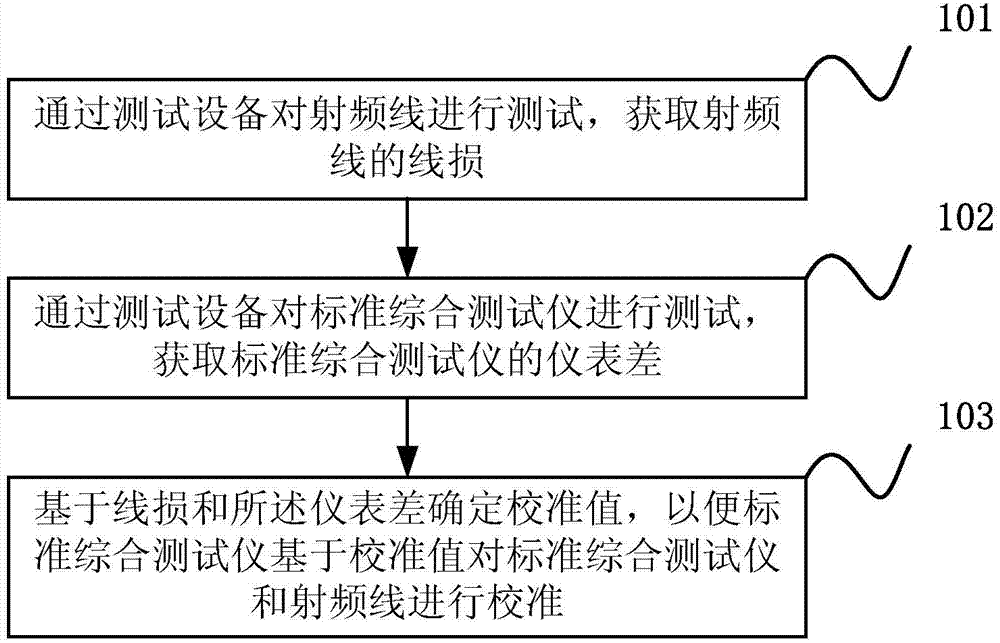

[0043] In view of the defects in the prior art, the embodiment of the present application proposes a calibration method for a mobile phone production test system, which is applied to a wireless terminal test system including a standard comprehensive tester and a radio frequency line, such as figure 1 shown, including the following steps:

[0044] Step 101. Test the radio frequency line by testing equipment to obtain the line loss of the radio frequency line;

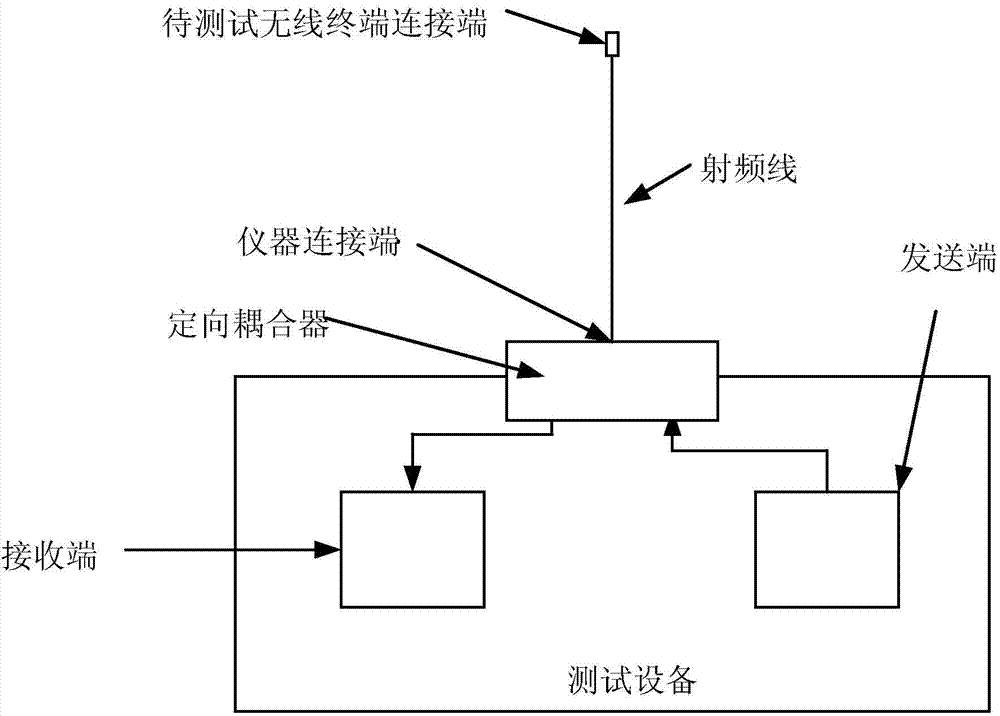

[0045] Specifically, the test equipment can be: a receiver and a module with the function of a vector network analyzer. Of course, it can also be other equipment, as long as the line loss of the radio frequency line and the instrument difference of the standard comprehensive tester can be obtained. .

[0046] Specifically, the process of obtaining the line loss includes:

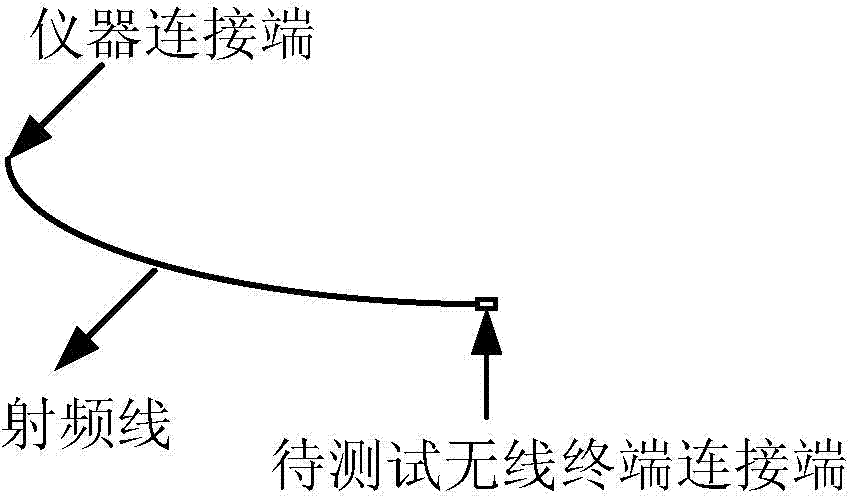

[0047] Connect the test equipment to the instrument connection end of the radio frequency line; send a signal to the radio frequency line through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com