Tea leaf winnowing and color sorting equipment

A color sorting and air sorting technology, which is applied in tea treatment before extraction, chemical instruments and methods, and separation of solids from solids by air flow, etc., can solve the problems of low production efficiency, difficulty in connecting equipment, and difficulty in tea differentiation. To achieve the effect of complete sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

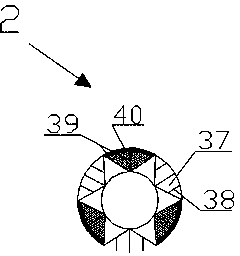

[0017] Example. A device for winnowing and color sorting of tea, which consists of Figure 1-Figure 4 As shown, the feed port 1 is included, the feed port 1 is connected with the material wheel 2, the conveying device 4 is arranged under the material wheel 2, the first material channel 5 is provided under the conveying device 4, and the bottom end of the first material channel 5 is provided with Miscellaneous discharge port 7, the upper left of miscellaneous discharge port 7 is provided with the first blower fan 6, and the upper right side of the first fan 6 is provided with winnowing room narrow part 10, and winnowing room narrow part 10 top is provided with winnowing room wide part 11, The first fan 6 blows the tea leaves to the narrow part 10 of the winnowing room, and heavy stones or branches etc. are discharged from the miscellaneous outlet 7. The side wall of the wide part 11 of the winnowing room is provided with a second fan 8, and There is a return slide 9, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com