Machining tool for main shaft barrel of impact crusher

A tooling and spindle technology, used in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve problems such as failure to meet technical requirements, and achieve the effect of good effect, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

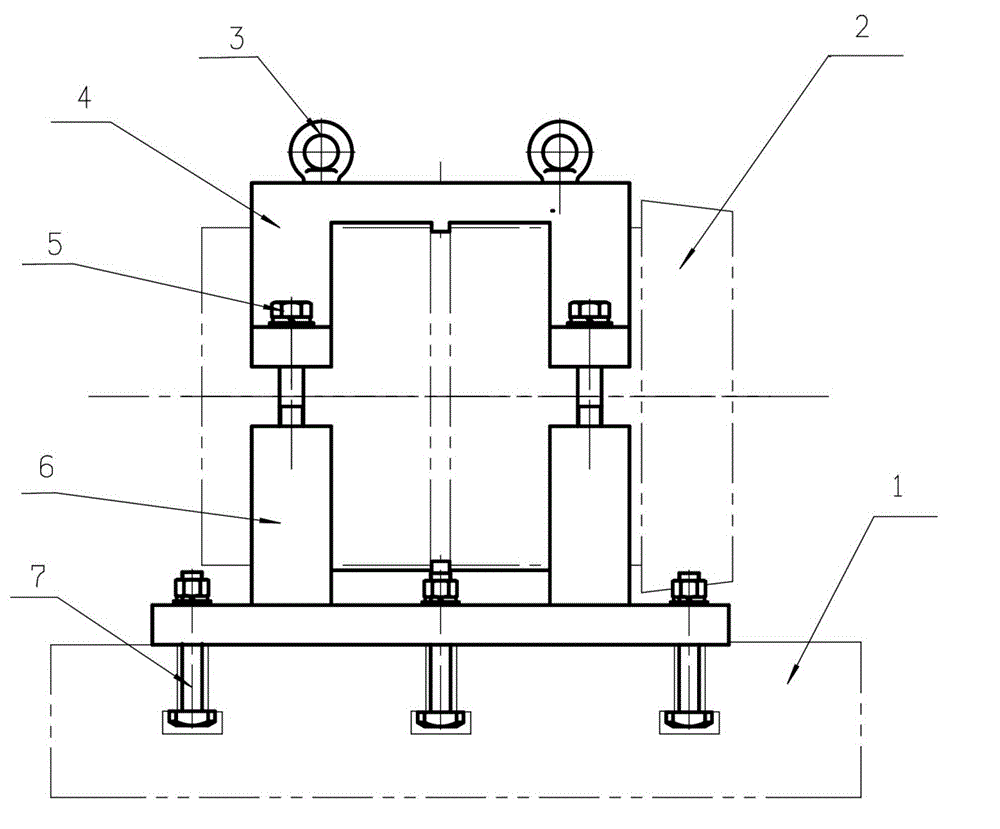

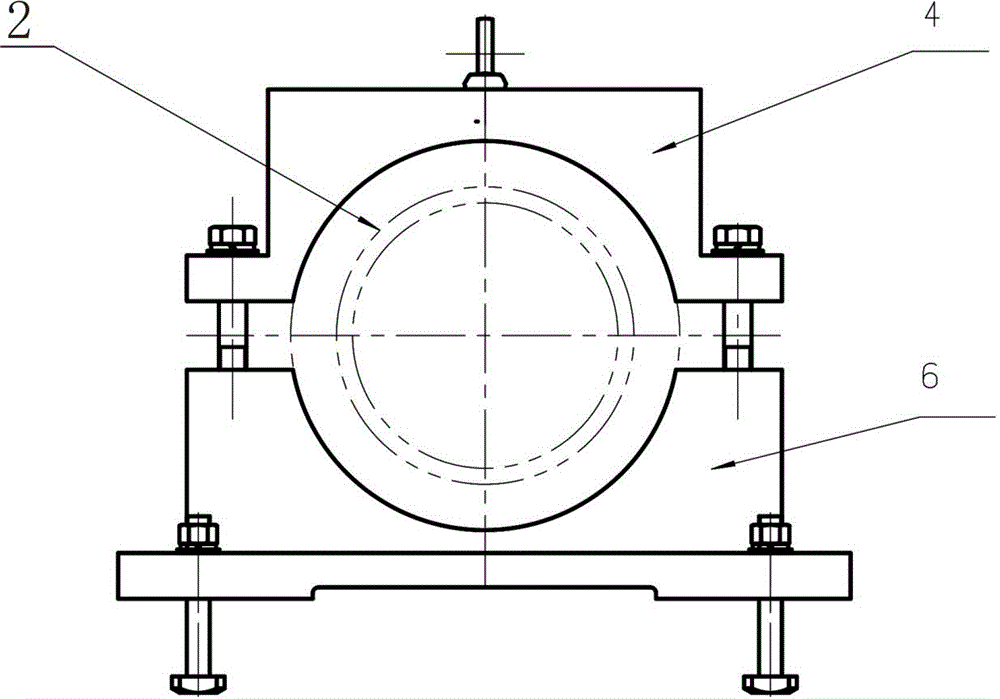

[0011] In the figure, above the boring machine workbench 1, there is an upper gland 4 for tooling, a hoisting ring 3 is arranged above the gland, clamping bolt perforations 5 are arranged on the side ears on both sides of the upper gland, and corresponding rings are arranged under the gland. The tooling base 6 of the base is provided with bolt thread holes corresponding to the perforation of the upper gland bolts on both sides of the base, and the bottom of the base is provided with base fixing bolts 7 connected with the boring machine workbench.

[0012] When in use, clamp the main shaft sleeve (workpiece) on the boring machine according to the drawing, align and lock it, and process it according to the requirements of the workpiece drawing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com