Manufacturing method of launching barge rocker arm hinged support

A manufacturing method and hinge bearing technology, which are applied in ship construction, manufacturing tools, ship parts, etc., can solve the problems of high manufacturing cost, high manufacturing difficulty, complicated procedures, etc., so as to reduce the difficulty of operation, reduce the difficulty of manufacturing, and avoid correction. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

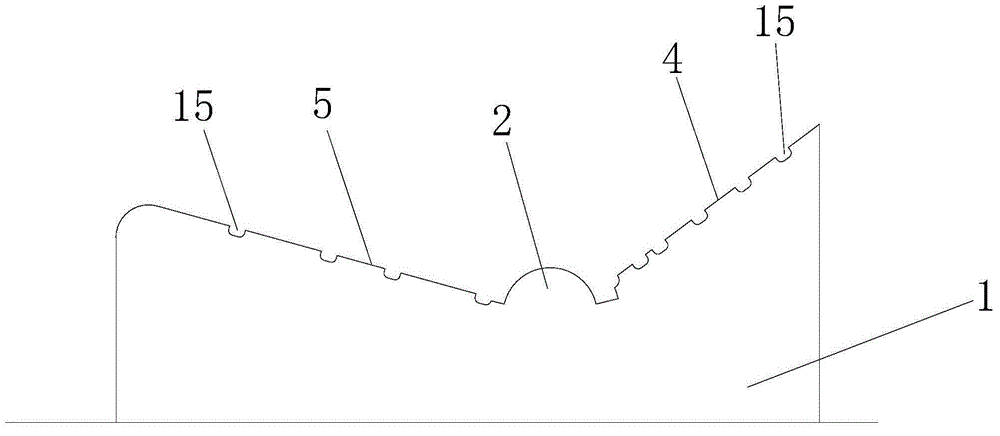

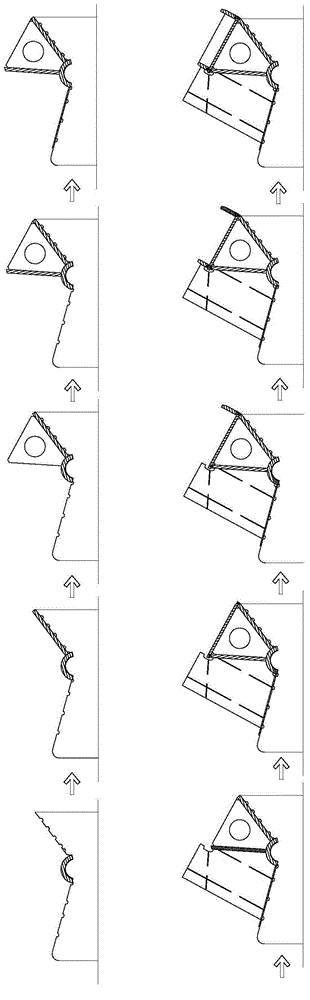

[0031] Such as Figure 1-4 As shown, the manufacturing method of the rocker hinge support of the launching barge in this embodiment includes the following steps:

[0032] 1) The manufacture of the tire frame 1, the middle part of the tire frame 1 is provided with a semicircular protrusion 2, and the semicircular sleeve 3 of the rocker hinge support can be placed upside down on the protrusion 2, and the protrusion 2 Both sides of the riser 2 are respectively extended with a first slope 4 and a second slope 5, the angle between the first slope 4 and the horizontal plane is 36.7°, and the angle between the second slope 5 and the horizontal plane is 15.3°;

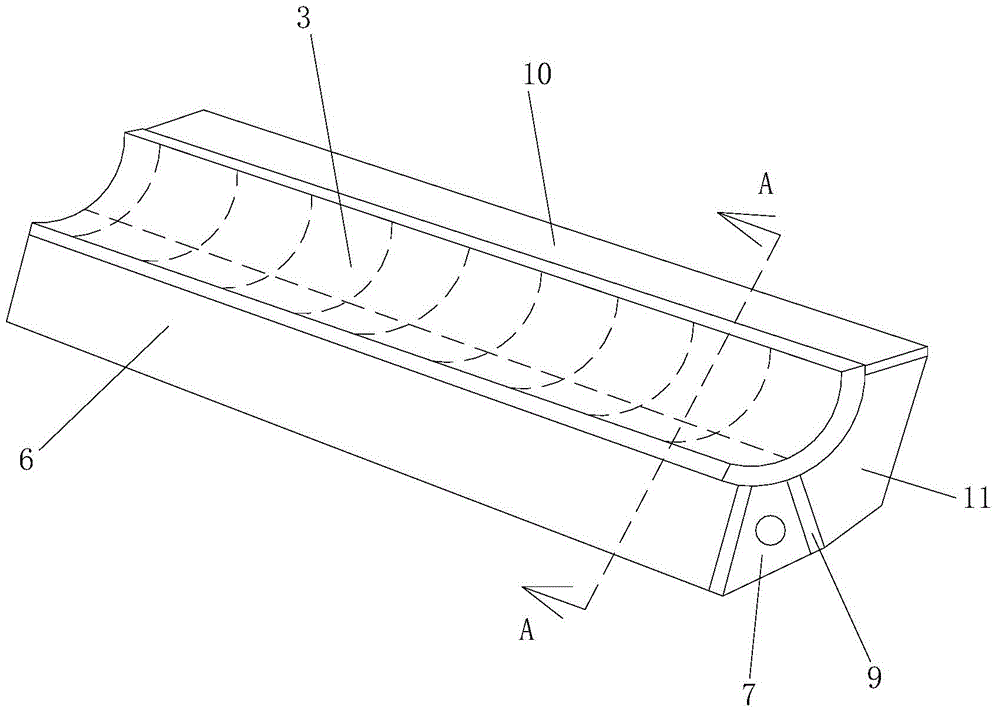

[0033] 2) Fixing of the half-circle sleeve 3, place the undercut of the half-round sleeve 3 for making the rocker hinge support on the protrusion 2, and fix it with a card code;

[0034] 3) Prepare the first support plate 6 for making the rocker hinge support, place the first support plate 6 on the first slope 4 and abut agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com