Method for preparing hydration-resistance CaO clinker

A technology of anti-hydration and calcium oxide, which is applied in the field of refractory preparation and can solve problems such as easy hydration

Inactive Publication Date: 2015-08-26

SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But CaO has a fatal disadvantage: easy hydration

To this end, countries have done a lot of research and made some progress. Som

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

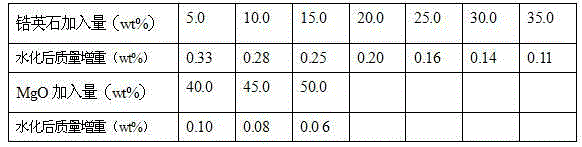

[0027] In this method, 200-2000 mesh 5.0-50.0wt.% zircon powder is added to 200-2000 mesh CaO, mixed evenly, pressed into balls or briquettes, and then calcined at a high temperature of 1260-1900°C, and carried out at a temperature above 1250-1900°C. The CaO sand with excellent hydration resistance was prepared by cold quenching treatment. Pictures of CaO sand as figure 1 As shown, its water absorption rate after placing it for 2 months is shown in Table 1.

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention discloses a method for preparing hydration-resistance CaO clinker and relates to a fireproofing material preparation method. The method includes: adding a certain amount of zircon powder into CaO, molding by compressing into balls and blocks after being mixed uniformly, conducting high-temperature calcination and cold quenching at the temperature of more than 1250 DEG C, and preparing the CaO clinker which is superior in hydrate resistance property. The method for preparing hydration-resistance CaO clinker is simple in process, convenient to operation, capable of effectively preparing the CaO clinker which can resist the hydration. The method firstly proposes that air cooling is conducted on the calcium oxide block body or ball body which is added with the zircon powder after high-temperature calcination at the temperature of 1250-1900 DEG C so that the hydration resistance property of CaO can be improved.

Description

technical field [0001] The invention relates to a method for preparing a refractory material, in particular to a method for preparing hydration-resistant CaO sand. Background technique [0002] CaO is an excellent refractory material, one of the most stable oxides, and hardly reacts with various molten metals. Compared with other refractory materials, CaO has the following significant advantages: [0003] 1. Good fire resistance [0004] Calcium oxide has a relatively high melting point and boiling point, its melting point is 2570°C, and its boiling point is 2850°C. at high temperature [0005] Under the condition of calcium oxide, the saturated vapor pressure is lower than that of other basic oxides, so it is a better refractory material. [0006] 2. Stable thermodynamic performance [0007] CaO is one of the most stable oxides and hardly reacts with various molten metals. According to the research on the properties of some oxides, at 1500 ° C, the absolute value of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C04B35/66C04B35/01C04B35/622

Inventor 曹大力

Owner SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap