Screening gravel grab bucket

A gravel and grab technology, which is applied to earth movers/excavators, construction, etc., can solve the problems that affect the strength of buildings, do not have screening or filtering, and grab stones with small volume, so as to improve the grab Efficiency, increased volume, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

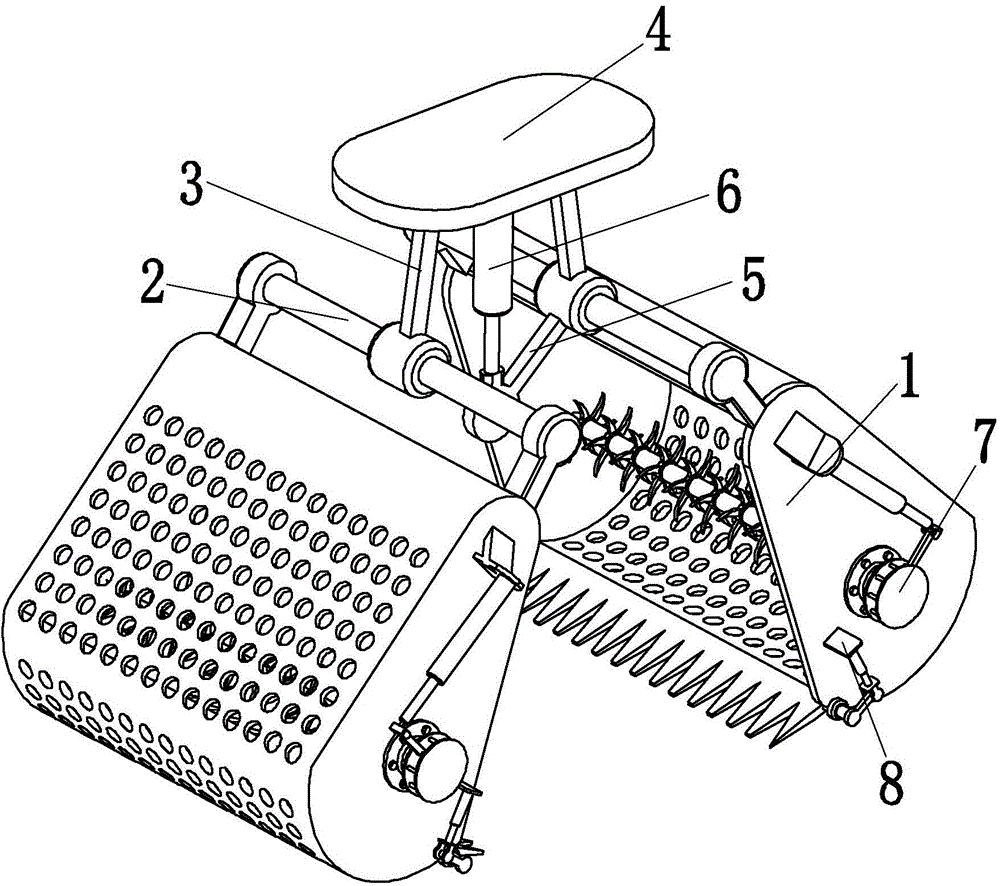

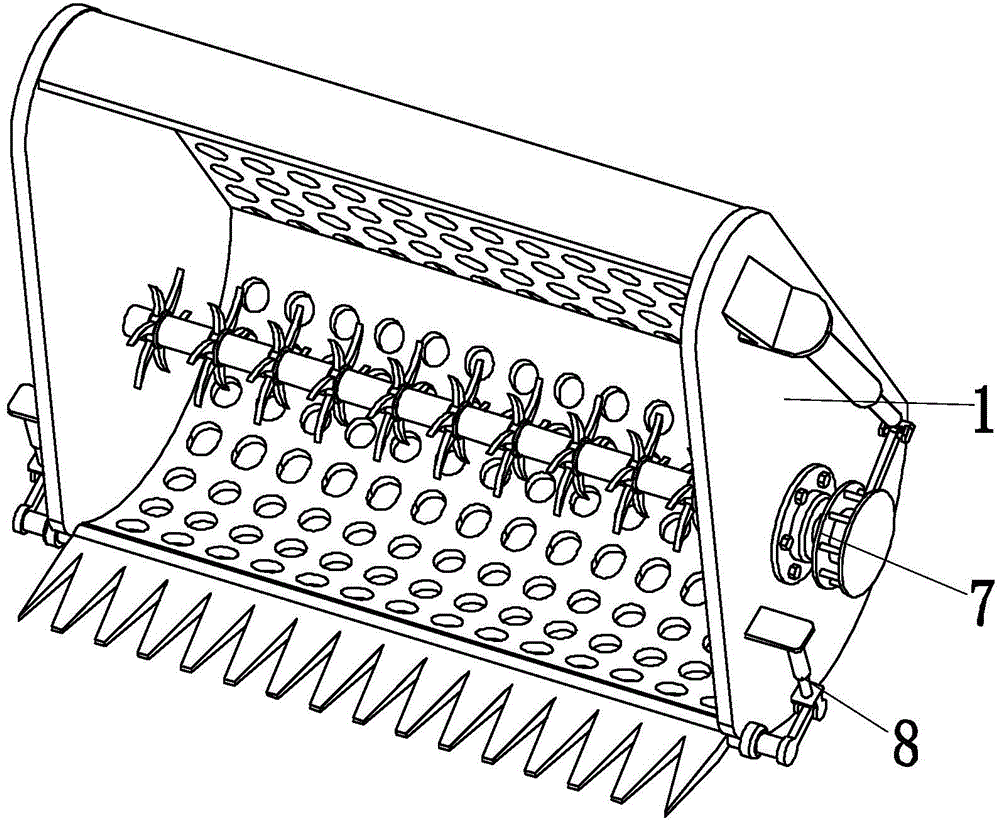

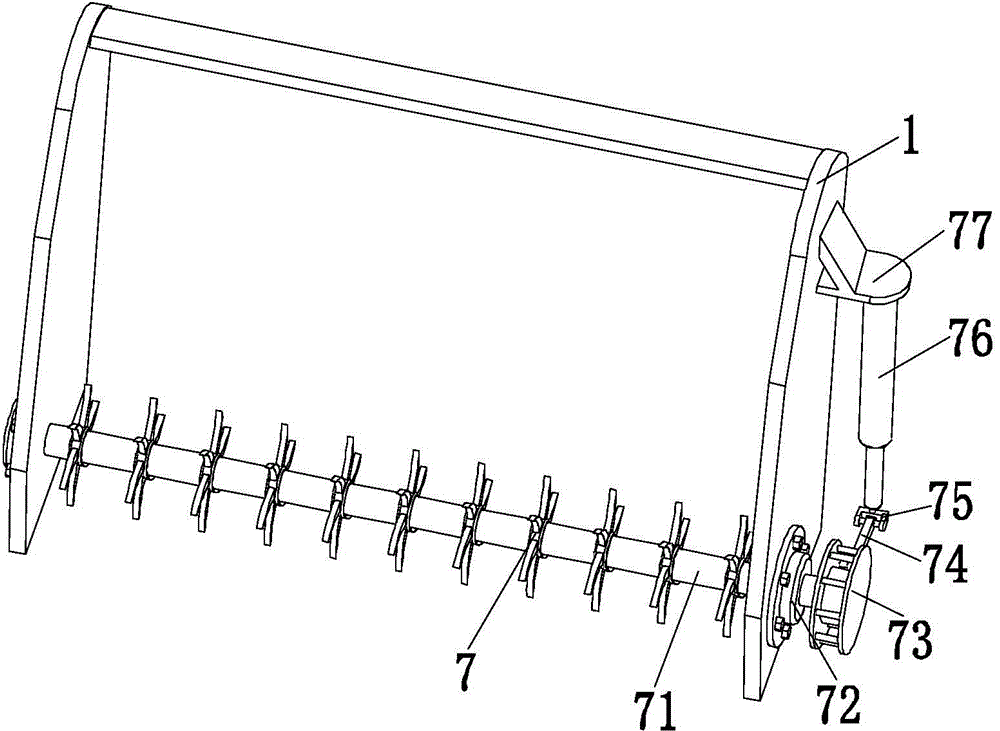

[0022] Such as Figure 1 to Figure 6 As shown, a sieveable gravel grab includes two grab buckets 1, two lower bearing beams 2, two upper supporting rods 3, upper bearing beams 4, two lower supporting rods 5, and a hydraulic cylinder 6 , two stirring and screening devices 7 and two claw head adjusting devices 8, the grab bucket 1 is composed of a left side plate, a right side plate and a main bucket, the left side plate and the right side plate are both shell-shaped structures, the main The bucket has an arc-shaped structure, the left side plate and the right side plate are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com