A riser filling valve with structure and operation state self-checking function

An operating state, riser technology, applied in wellbore/well valve devices, sealing/packing, wellbore/well components, etc. Difficulty in finding and discharging faults, lagging in the daily management of riser filling valve equipment, etc., to achieve the effects of improving monitoring capabilities, improving operational stability and reliability, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

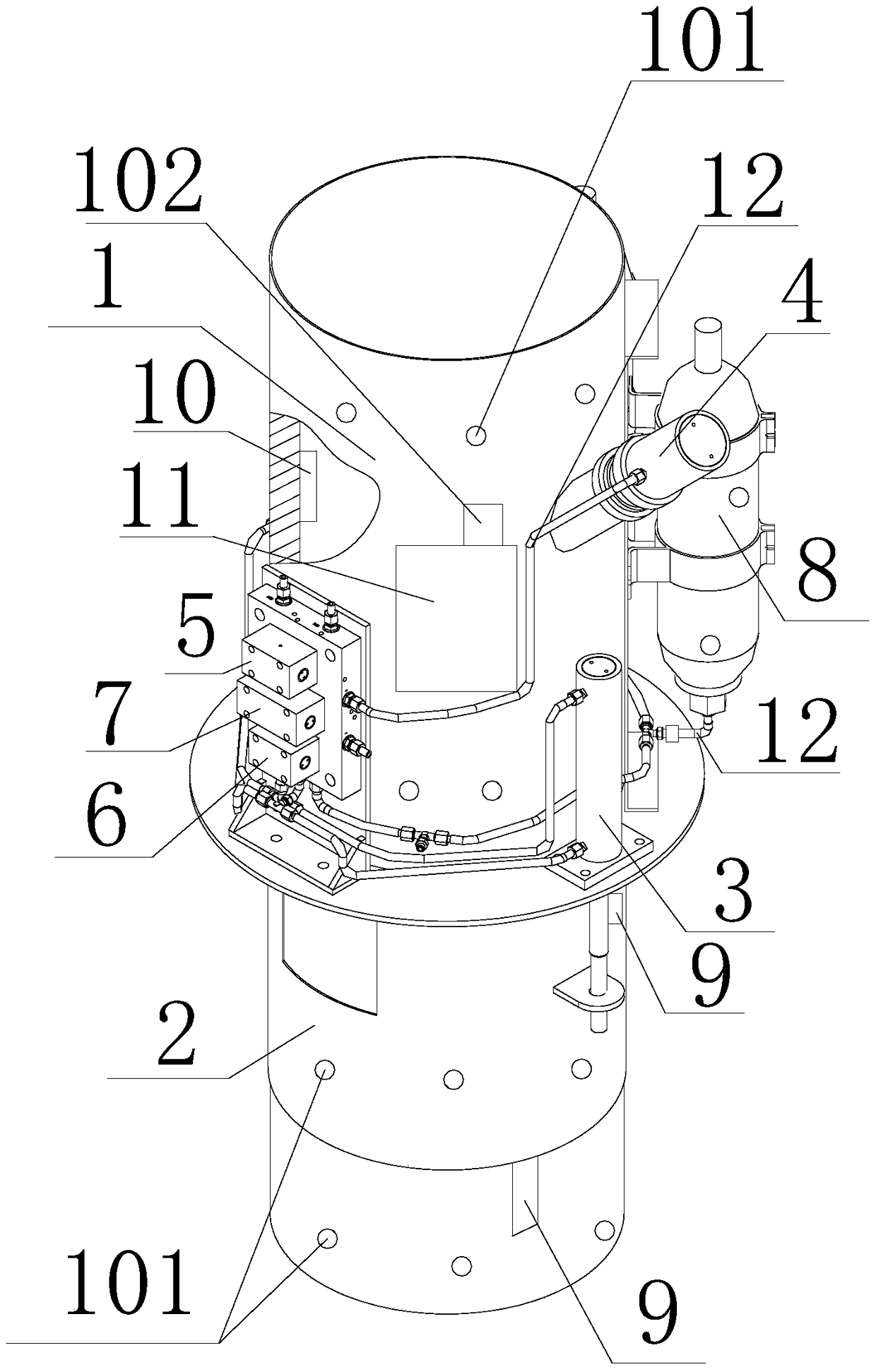

[0012] Such as figure 1 The riser filling valve with self-checking function of structure and operating status includes riser main body 1, riser hatch 2, driving cylinder 3, balance valve 4, main control valve 5, lock valve 6, switching valve 7. Accumulator 8, stroke sensor 9, pressure sensor 10, ultrasonic flaw detection device and detection control device 11, wherein the main control valve 5, lock valve 6, switching valve 7, energy storage device 8 and detection control device 11 are all located in the isolation On the outer surface of the riser body 1, the riser hatch 2 covers the lower part of the riser body 1 and is slidably connected to the riser body 1 through the driving cylinder 3. The balance valve 5 is additionally embedded in the riser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com