Rapid oil drain device with one-way valve type oil plug of oil pan

A technology of oil draining device and oil pan, which is applied in the direction of adding/discharging lubricants and lubricating parts, etc., which can solve the problems of long time, low oil draining efficiency, and high risk, so as to save rest time, Efficient and fast oil draining, reducing the intensity of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

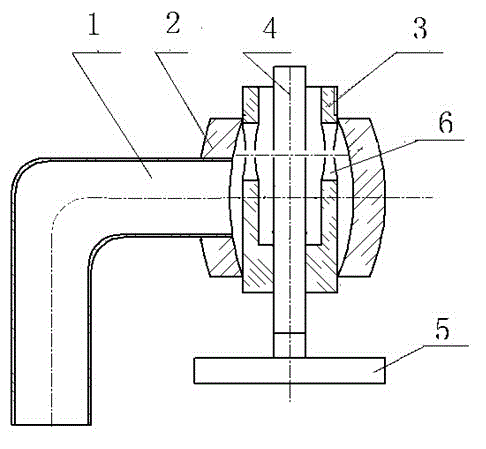

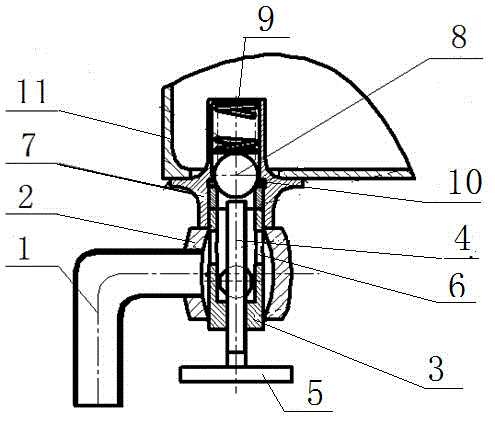

[0019] Oil sump one-way valve type oil plug fast oil drain device, such as figure 1 As shown, it includes an elbow 1 with a curvature of 90°. One end of the elbow 1 is welded to a body 2. The body 2 is a hollow spherical structure. Elbow 1. A hollow tubular mandrel 3 is fixed vertically inside the body 2 , and the connection between the mandrel 3 and the body 2 is also sealed and welded. The top end of the mandrel 3 is open and the bottom end is closed. The part of the upper end of the mandrel 3 exposed to the body 2 is provided with an external thread. The external thread of the mandrel 3 matches the internal thread of the oil drain seat 7 of the oil pan 11, so Connect to the inner hole of the oil drain seat 7 by threads. The part of the mandrel 3 included by the body 2 is provided with two round holes 6 , the two round holes 6 are of the same size and opposite to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Camber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com