Lighting device having small tube seat

A technology of lighting device and tube socket, which is applied in the directions of lighting device, lighting device parts, lighting and heating equipment, etc., to achieve the effects of high support force, reduced assembly cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

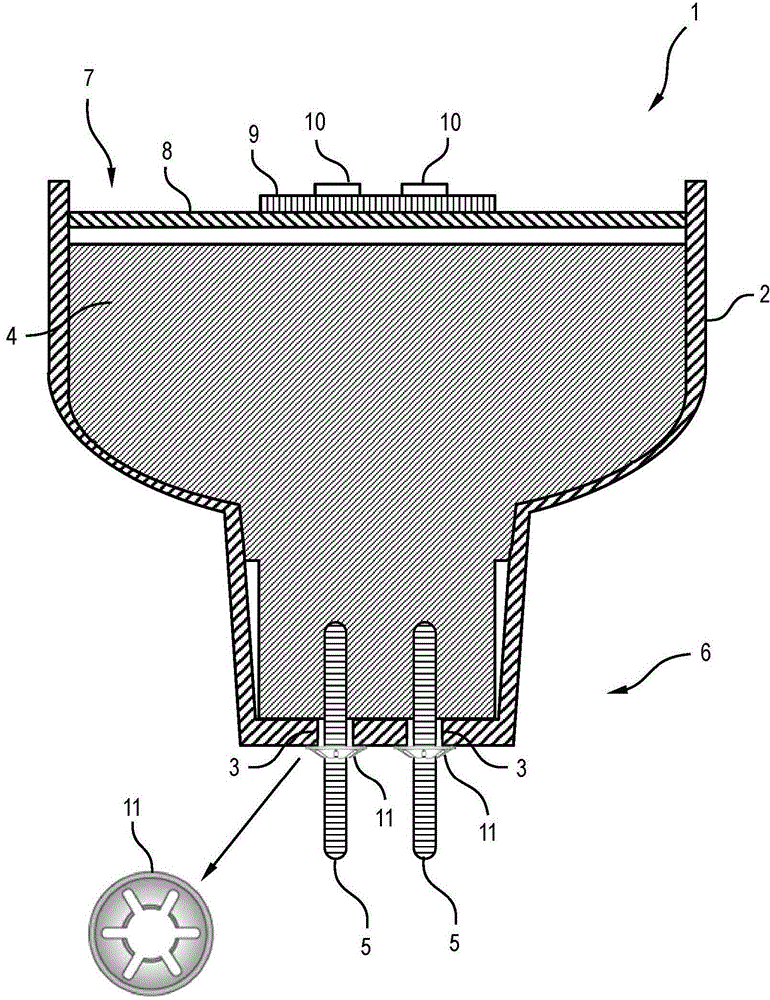

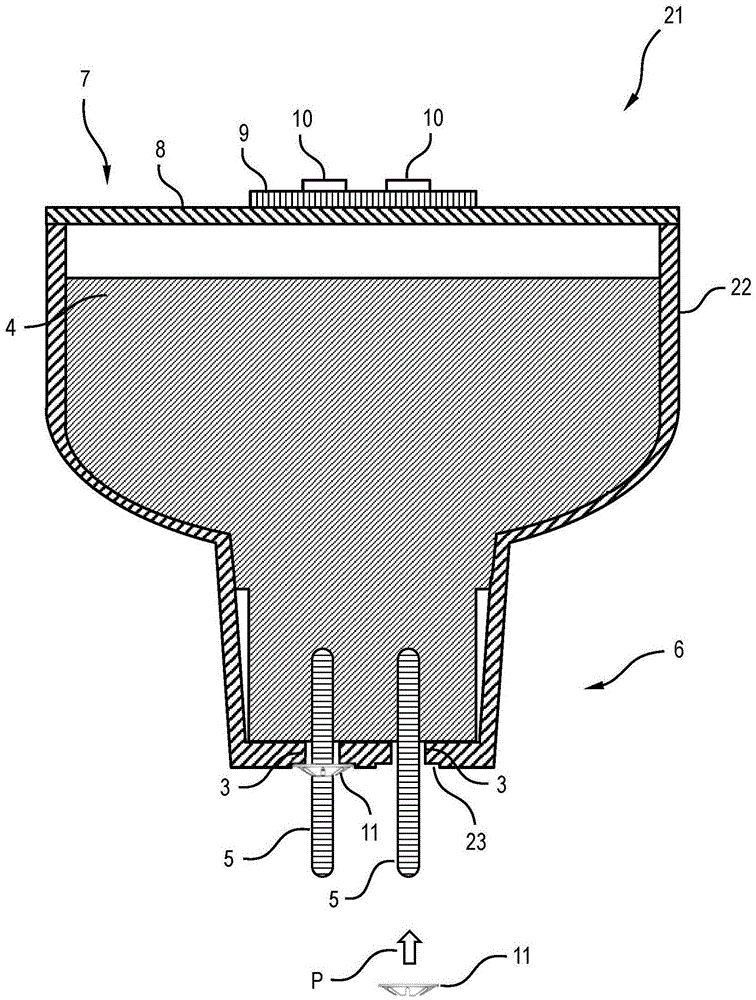

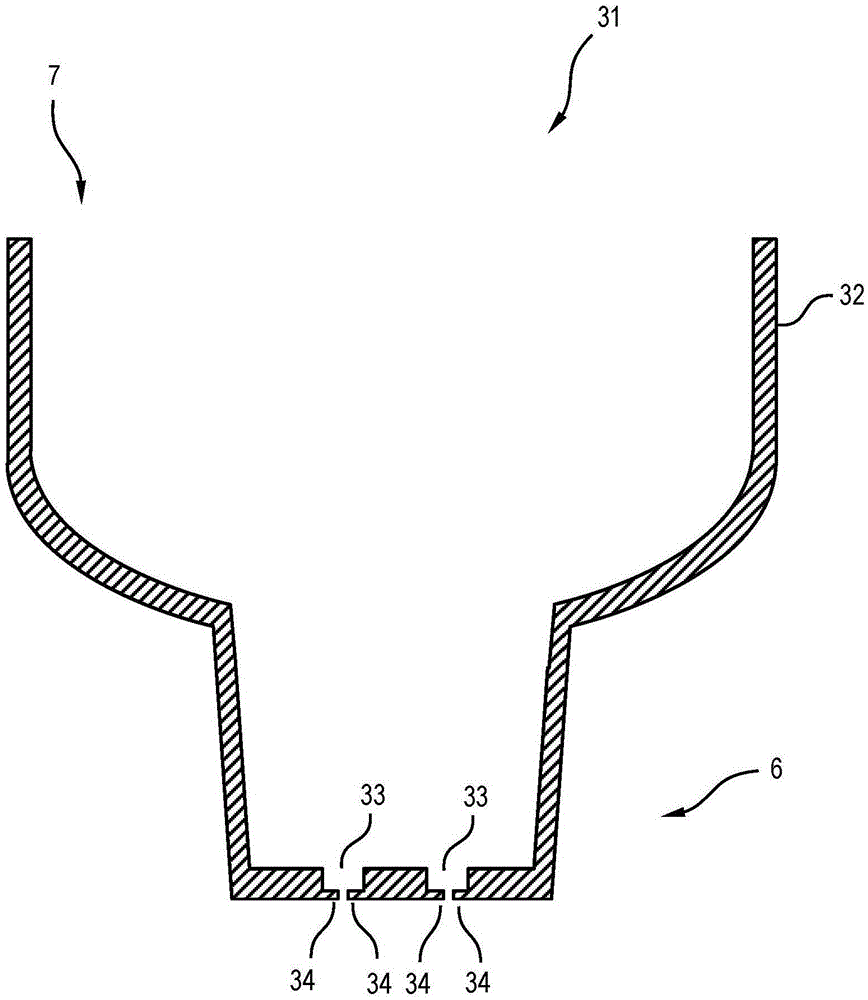

[0036] figure 1 A side sectional view of a lighting device in the form of a retrofit lamp 1 for replacing a conventional MR16 lamp according to a first embodiment is shown.

[0037] The retrofit lamp 1 has a housing 2 which is open on its front side and has two feedthroughs 3 on its rear side. A driver 4 in the form of drive electronics is accommodated in the housing 2 . Fastened on the driver 4 , for example welded, are two contact pins 5 , which protrude partially through the lead-through 3 . The contact pins 5 together with the counter area 6 of the housing 2 form a socket of the type GU5.3. The sockets 5, 6 are suitable for use in matching lamp sockets.

[0038] The front open side 7 of the housing 2 is covered by a cover 8 on which a base body 9 for the semiconductor light source in the form of an LED 10 is arranged on the outside. Here, the LED 10 emits its light into the front half area. Not shown but there could be a light-transmissive (transparent or opaque) cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com