Magnetic flux modulated composite motor in parallel hybrid excitation structure

A technology of magnetic flux modulation and mixed excitation, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of small output torque, low power factor, etc., achieve the effect of improving overload capacity, high electric excitation efficiency, and realizing brushless

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

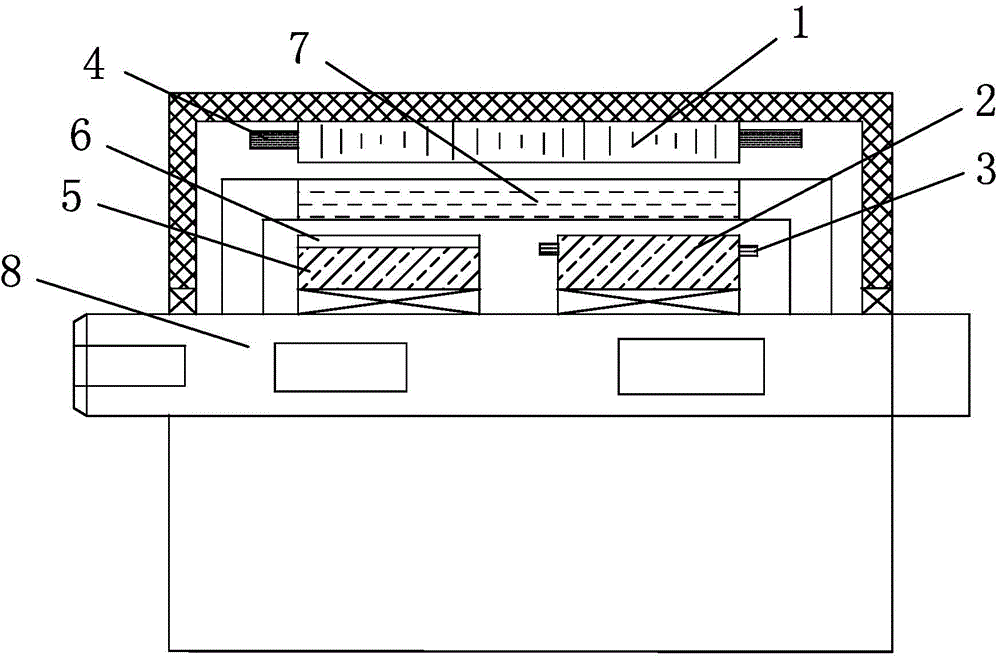

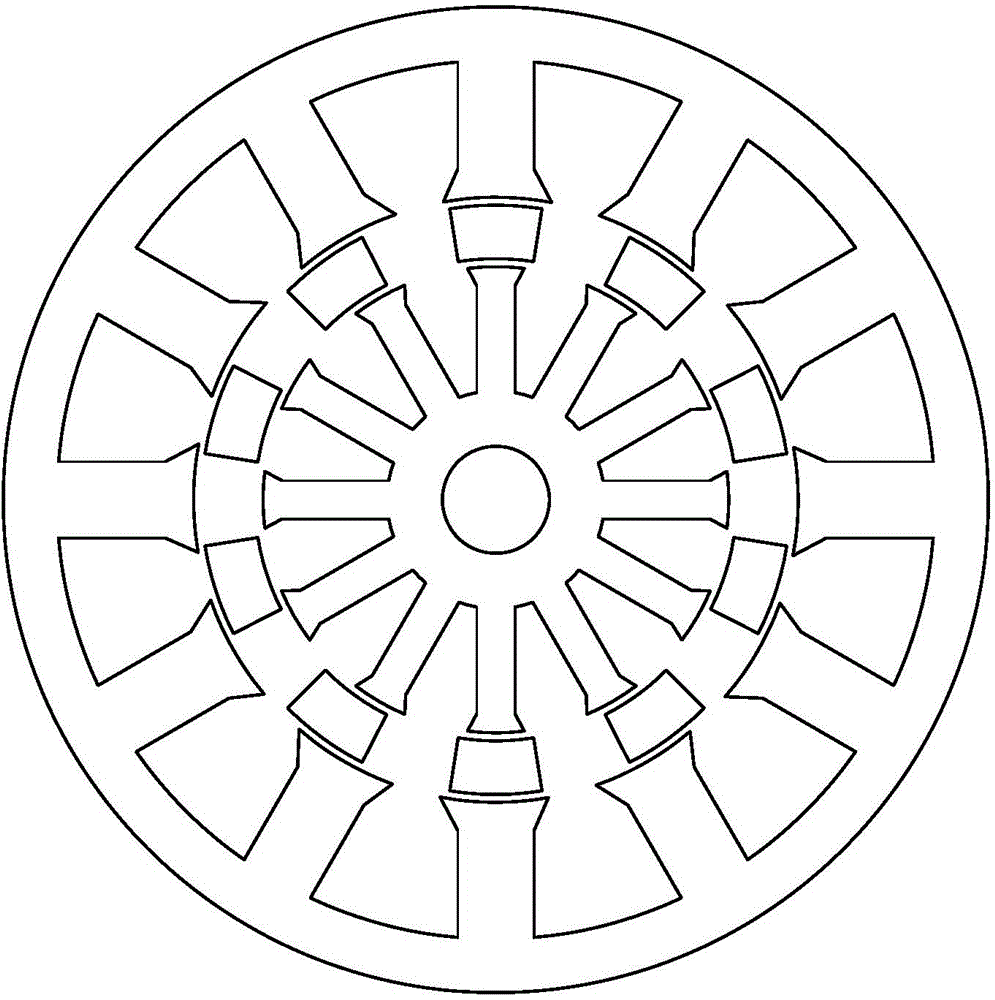

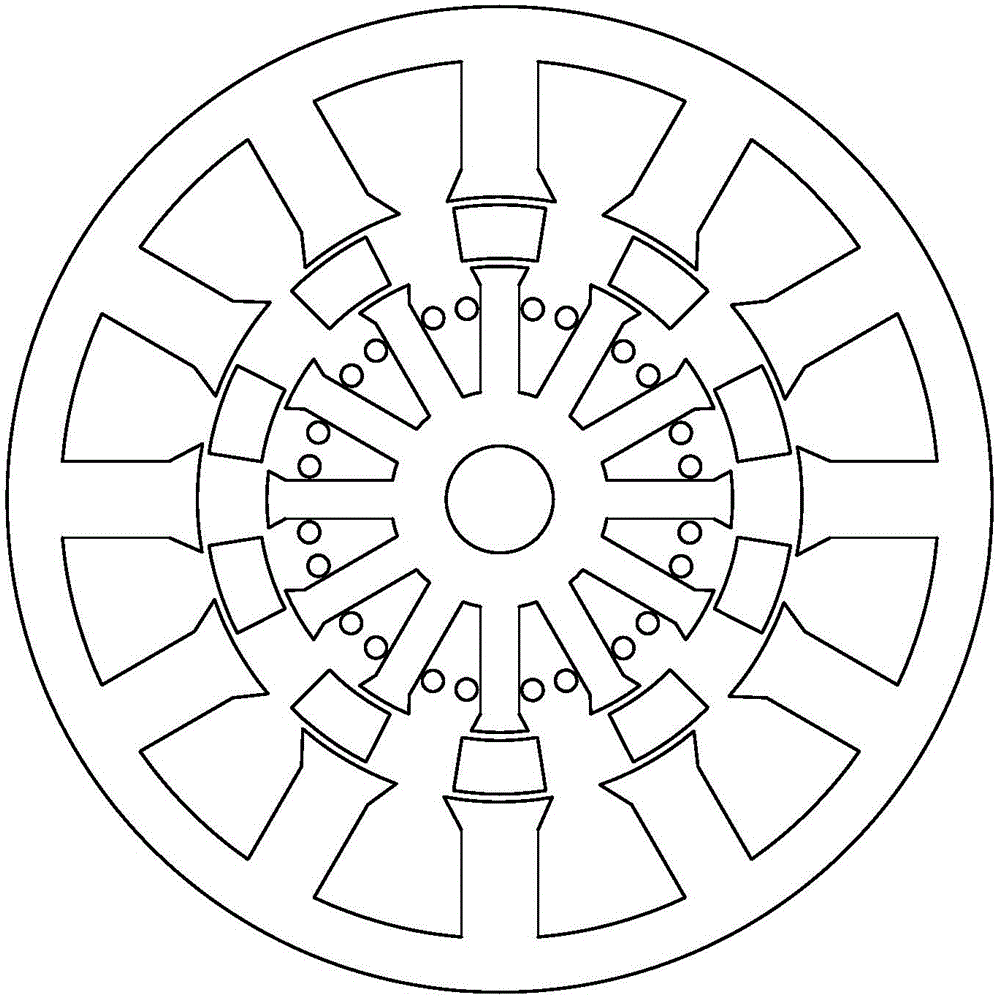

[0011] Specific implementation mode 1. Combination Figure 1 to Figure 3 Describe this specific embodiment, the magnetic flux modulation composite motor of the parallel hybrid excitation structure described in this specific embodiment includes an outer stator 1, a permanent magnet inner stator 5, an electric excitation inner stator 2, a keyway 8, an excitation winding 3, an electric The armature winding 4, the permanent magnet 6 and the magnetic ring rotor 7, the outer stator 1 is fixed on the motor casing, the armature winding 4 is wound on the outer stator 1, the permanent magnet inner stator 5 and the electric excitation inner stator 2 They are respectively fixed on the left and right sides of the motor shaft and separated by an air gap. The permanent magnet 6 is fixed on the core of the permanent magnet inner stator 5, the excitation winding 3 is wound on the iron core of the electric excitation inner stator 2, and the magnetic ring rotor 7 is located on the inner and outer...

specific Embodiment approach 2

[0016] Embodiment 2. The difference between this embodiment and the parallel hybrid excitation structure magnetic flux modulation composite motor described in Embodiment 1 is that the permanent magnet inner stator 5 adopts a built-in tangential magnetic steel structure or a surface-mounted Type magnetic steel structure is realized.

specific Embodiment approach 3

[0017] Specific embodiment three. The difference between this specific embodiment and the magnetic flux modulation compound motor with parallel hybrid excitation structure described in specific embodiment two is that the number of pole pairs of the permanent magnet inner stator 5 is the same as that of the electric excitation inner stator 2 The number of pole pairs is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com