Multi-range continuously variable transmission

A continuously variable transmission, multi-range technology, applied to the transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of poor efficiency, decoupling of the transmission device, and inability to drive continuously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

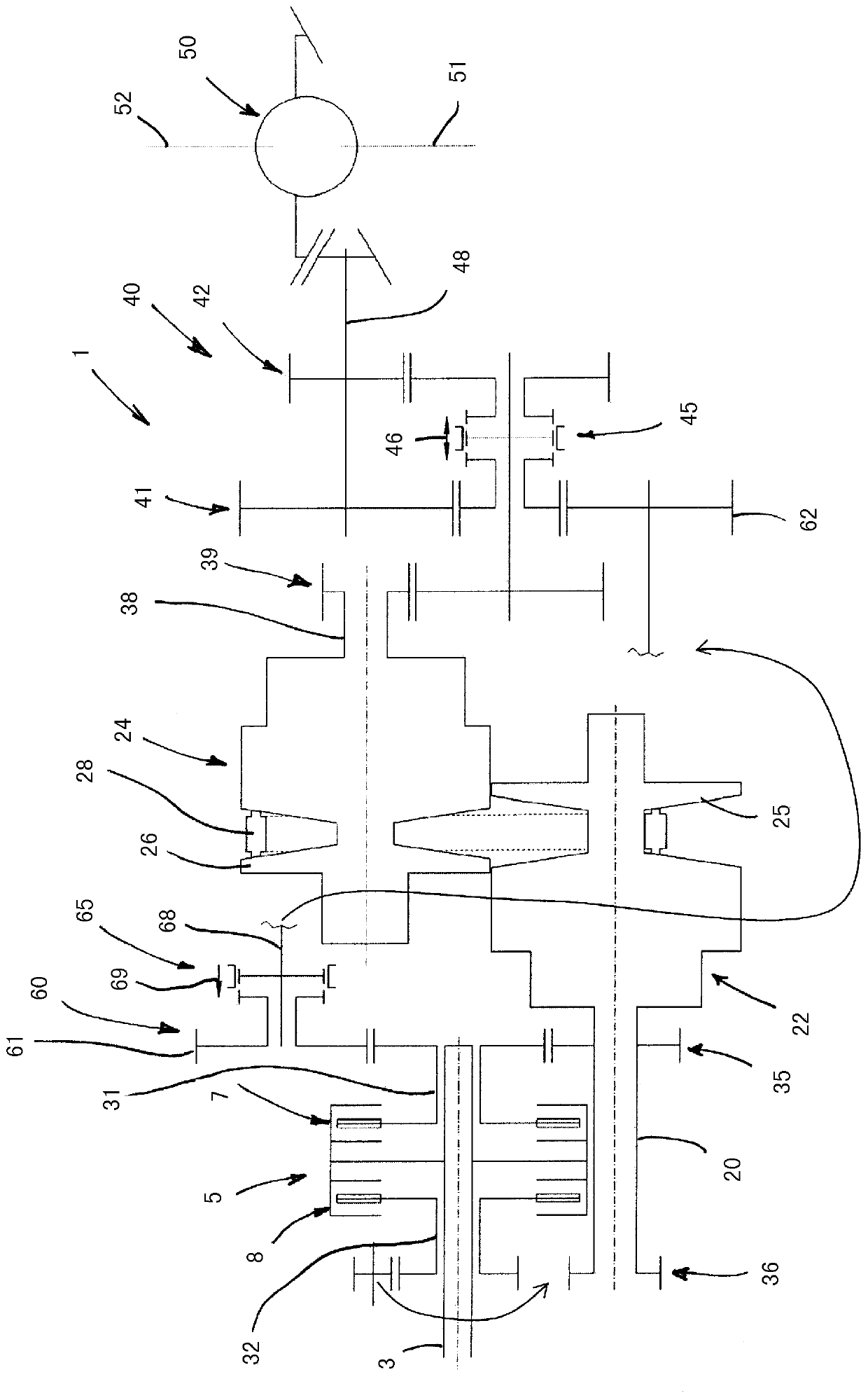

[0018] exist figure 1 A simplified cross-sectional view of a multi-range continuously variable transmission according to the present invention is shown in . The multi-range continuously variable transmission 1 is particularly well suited for use in commercial vehicles, since the vehicle is driven at low rotational speeds but with high output-side torque. The multi-range continuously variable transmission 1 is used, for example, in tractors.

[0019] Conventional multi-range continuously variable transmissions have the disadvantage, in particular, of interrupting the force flow during a range change between two operating ranges. This interruption of traction also makes it difficult to switch over when starting a heavily loaded vehicle on an incline. A cost-effective improved shifting between operating ranges is provided by the multi-range continuously variable transmission 1 according to the invention. Here, in particular, full-load switching between these two operating rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com