Method for producing crystalline semiconductor film

A manufacturing method and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve problems such as component differences and uneven crystallinity, and achieve the effect of reducing the difference in transistor characteristics and effective laser annealing treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] One embodiment of the present invention is described below.

[0060] Using 50 nm-thick amorphous Si as a non-single crystal semiconductor film, pulsed laser irradiation was performed by changing the number of times of irradiation under the following conditions.

[0061] Excimer laser: LSX315C / wavelength 308nm, frequency 300Hz

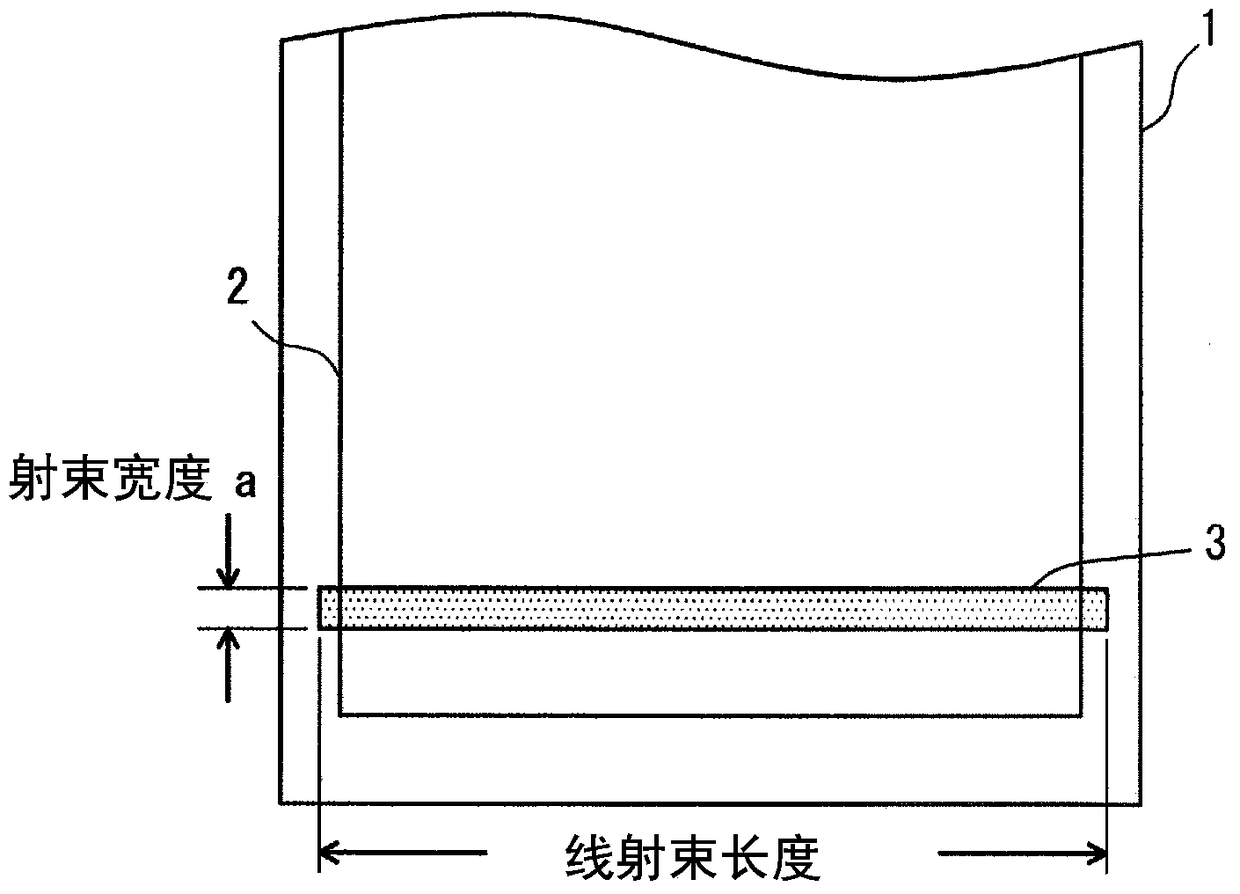

[0062] Beam size: beam length 500mm × beam width 0.16mm

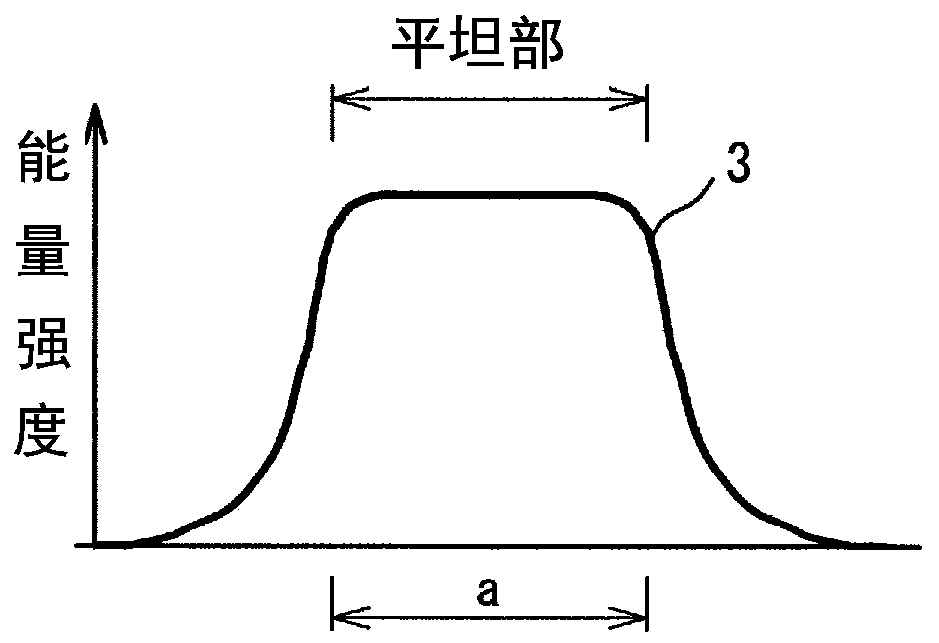

[0063] The beam width is the flat portion in the high-intensity region where the maximum energy intensity is 96% or more

[0064] Scanning pitch: 40μm~80μm

[0065] Irradiation pulse energy density: 370mJ / cm 2

[0066] Channel length: 20μm

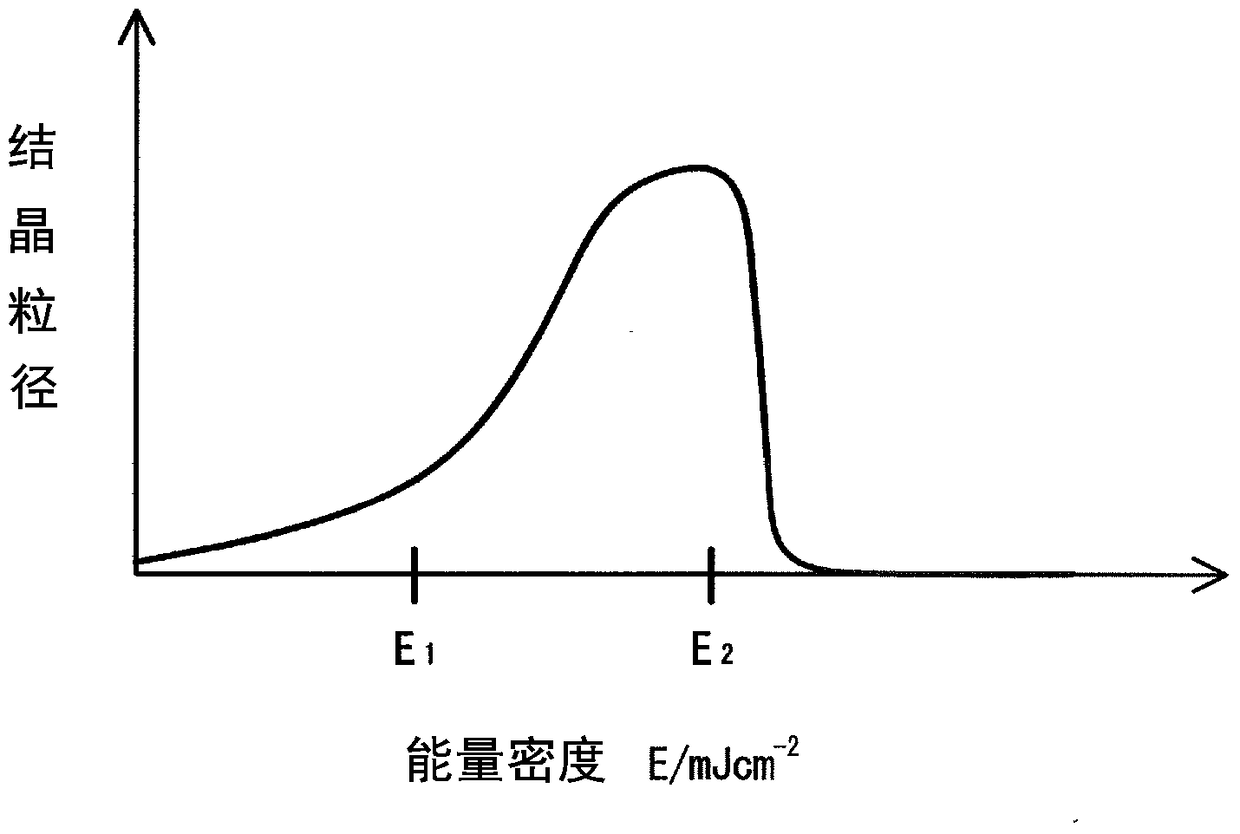

[0067] The irradiation pulse energy density of the above-mentioned pulsed laser is below the irradiation pulse energy density capable of producing microcrystals, and within the range of irradiation times from four times to eight times, the crystal grain size gradually grows, and when the number of times of irradiation exceeds eight times When , t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap