Piezoelectric vibrator

A piezoelectric vibrator and vibrator technology, applied in electrical components, impedance networks, etc., can solve the problems of limited miniaturization of the vibrator, gaps and cracks at the end of the vibrator, and increasing the length of the electrodeless part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

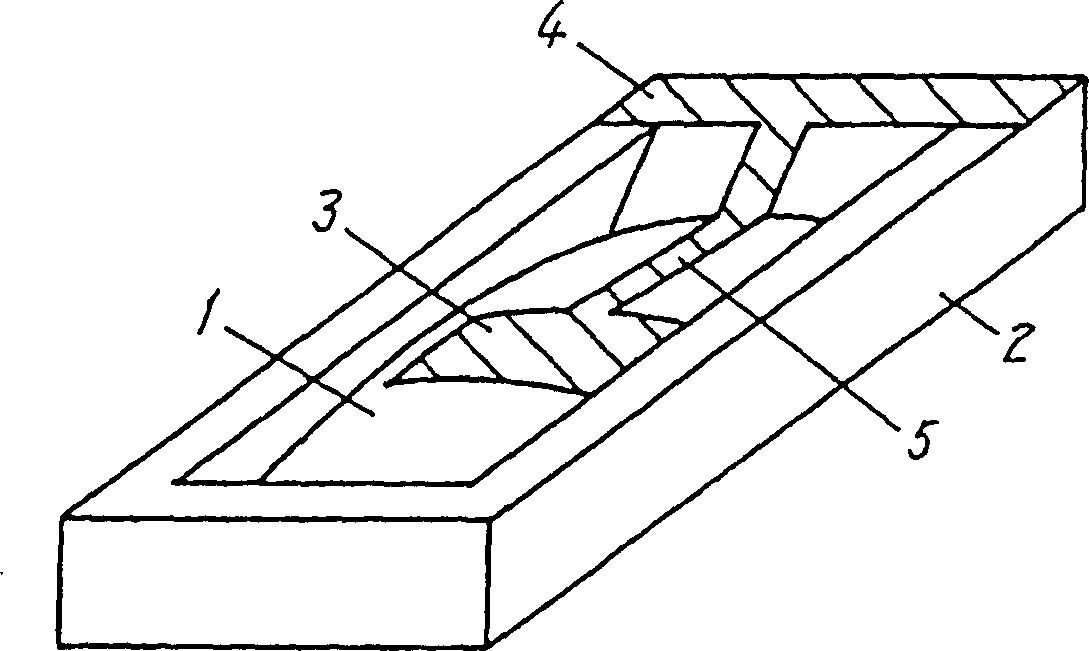

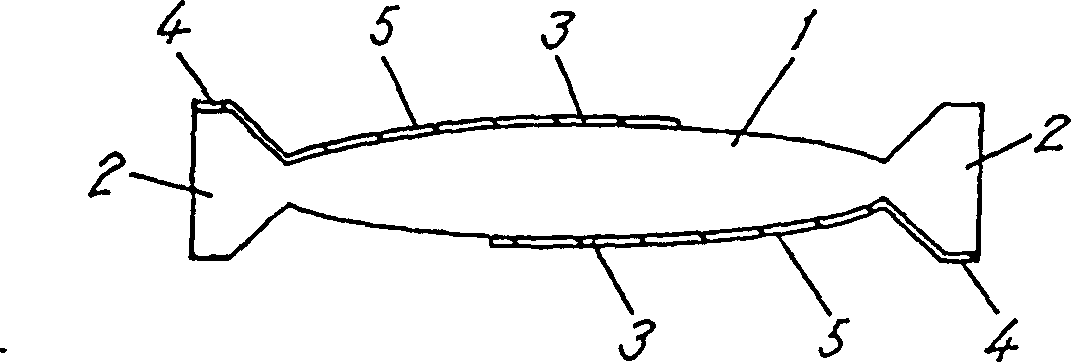

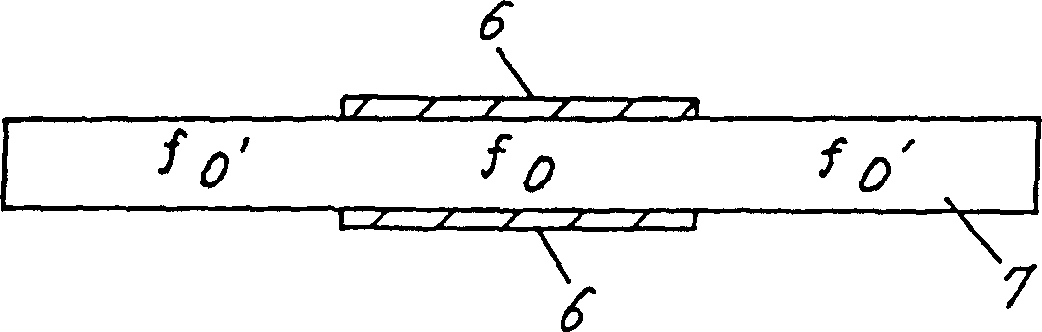

[0042] Refer to the following figure 1 , figure 2 , Figure 4-Figure 9 , an embodiment of the present invention will be described. exist figure 1 Among them, 1 is a piezoelectric vibrator, 2 is a supporting part integrated with the vibrator 1, 3 is an electrode for excitation provided opposite to the front and back of the vibrator 1, 4 is an electrode for external connection, and 5 is for external lead-out electrode.

[0043] As an example, consider a vibrator using a lithium tantalate single crystal X plate, in which thickness shear vibration is the main vibration. Now if it is considered that the resonant frequency of the vibrator is 20 MHz, the thickness H of the vibrator is about 100 μm. In a conventional design example, since L / H is set to 14 or more, assuming that L / H is equal to 14, the length L of the vibrator in the longitudinal direction when H is about 100 μm is about 1.4 mm. Calculate the attenuation degree of the vibration displacement at this time. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com