Semiconductor imaging device and manufacturing method thereof

A technology of imaging device and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem that it is difficult to obtain semiconductor imaging devices, and achieve the effect of reducing characteristic differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

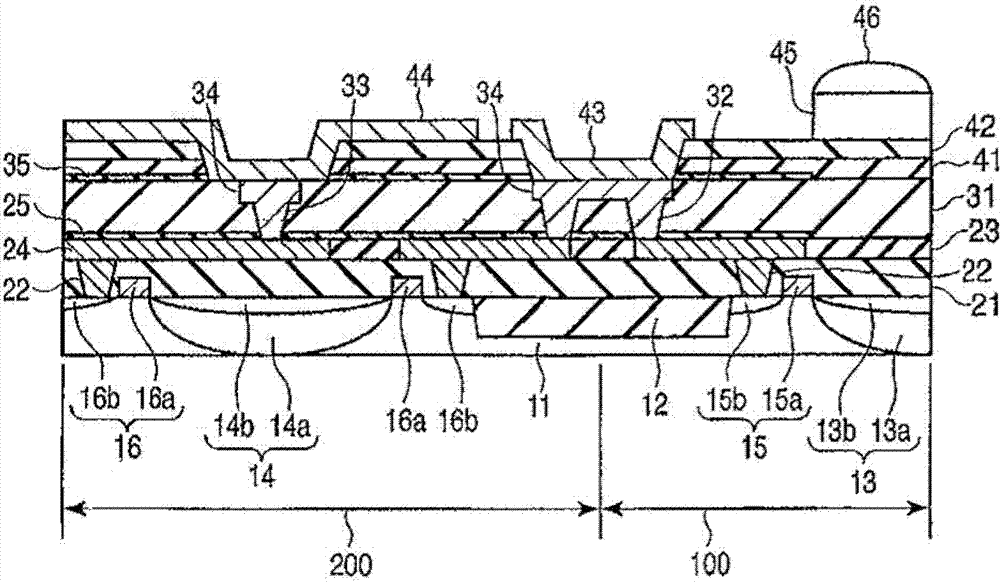

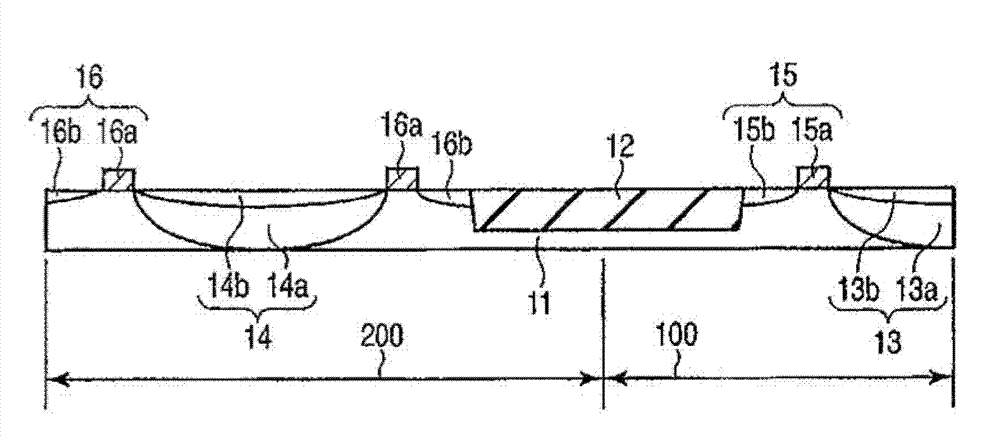

[0017] Embodiments will be described below with reference to the drawings.

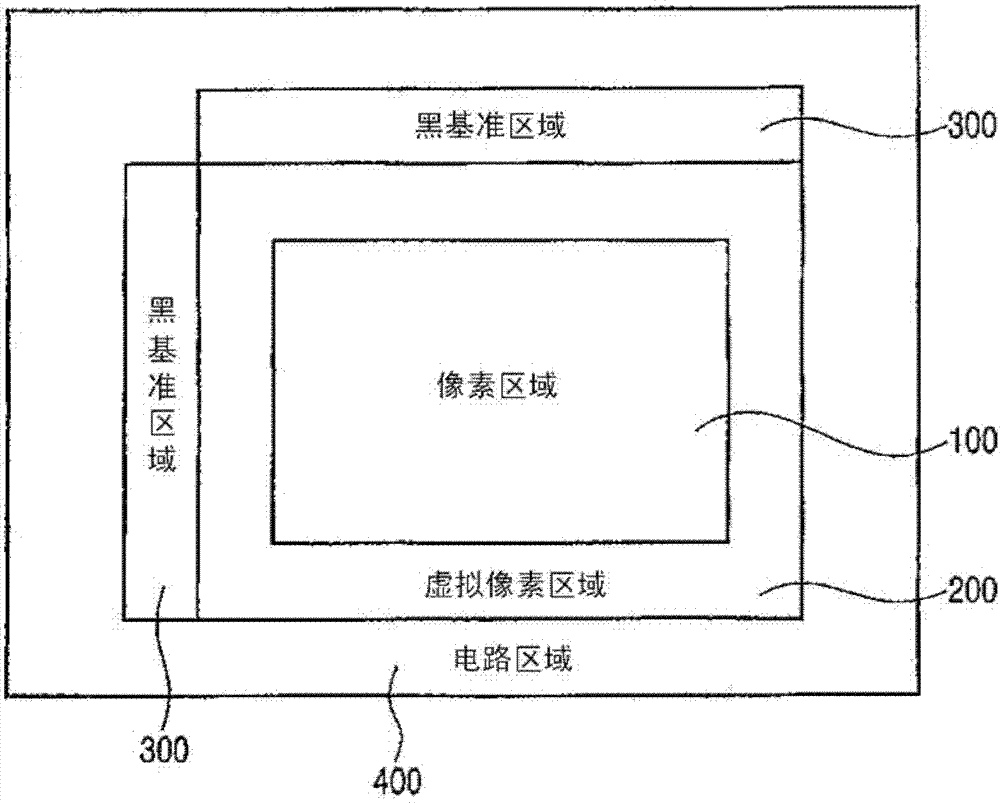

[0018] figure 1 It is a diagram schematically showing the overall configuration of the semiconductor imaging device (CMOS image sensor) according to the embodiment.

[0019] Such as figure 1 As shown, the semiconductor imaging device includes a pixel area 100 , a dummy pixel (Dummy Pixel) area 200 , a black reference area 300 and a circuit area 400 .

[0020] In the pixel area 100, a plurality of pixels are arranged in a matrix. In each pixel, a photodiode (photoelectric conversion element) and a MOS transistor are provided. A dummy pixel region 200 is arranged around the pixel region 100 . The dummy pixel region 200 is not used in the actual imaging operation, but is provided due to requirements in the manufacturing process and the like. The black reference area 300 is an area where a black reference signal is generated. In non-pixel regions such as the dummy pixel region 200 and the black refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com