Smashing separating and drying method for viscous fermented feed

A technology of fermented feed and drying method, which is applied in the direction of feed, drying gas arrangement, drying, etc., and can solve the problem of easy-bonding agitator, orifice plate and feeder, easy-bonding agitator and feeder, and inadaptability Viscous materials and other problems can be achieved to shorten the drying time, reduce the adhesive force and increase the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

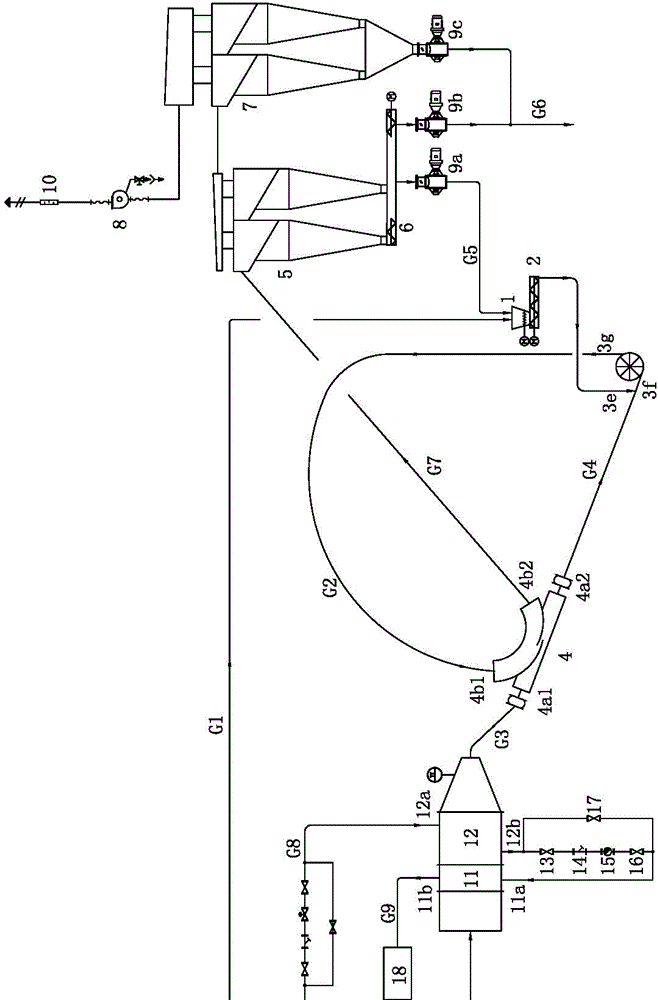

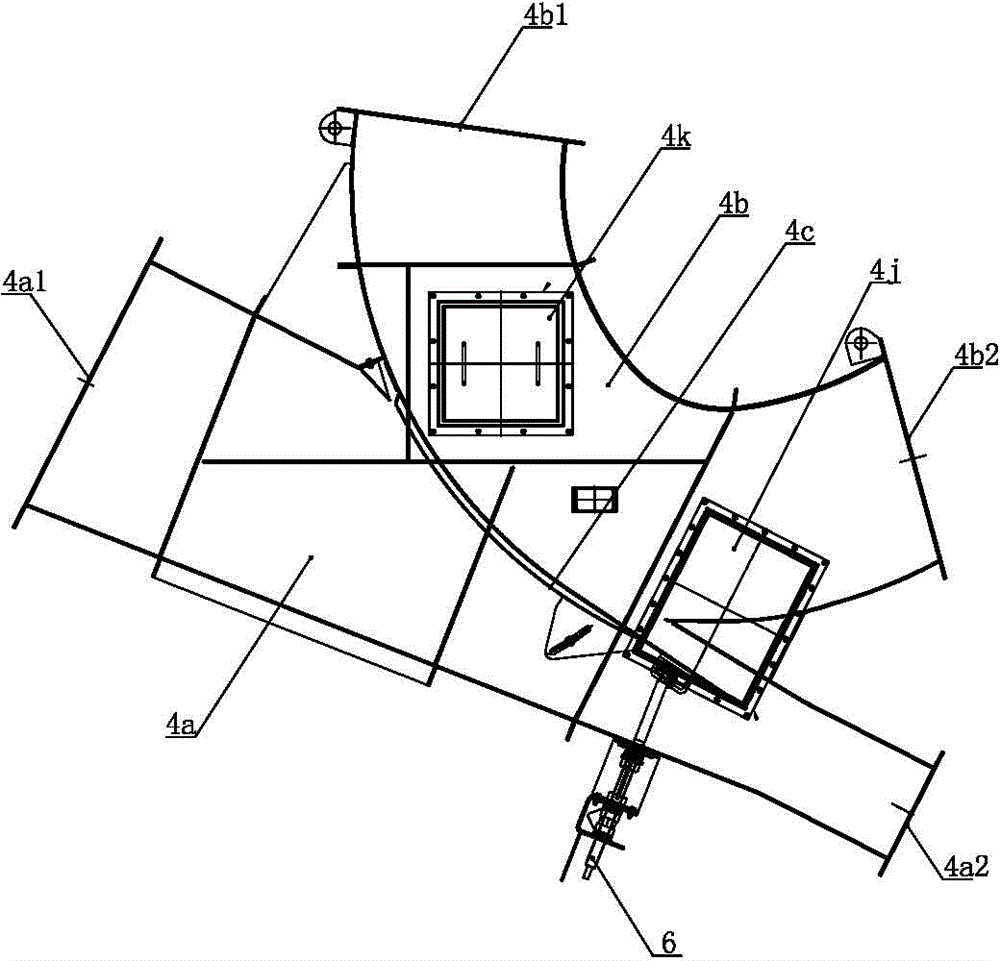

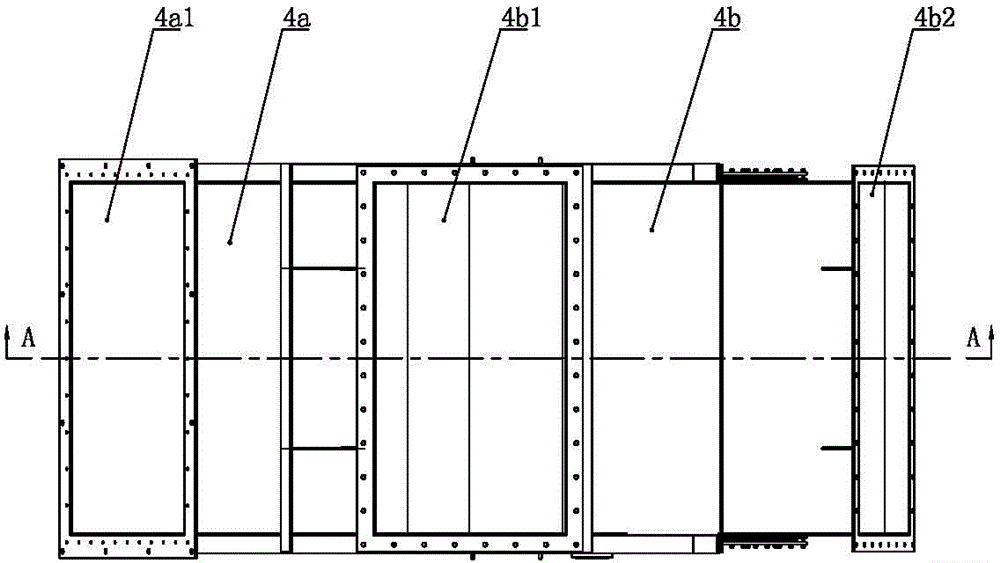

[0032] Such as figure 1 As shown, the pulverization, separation and drying system of viscous fermented feed includes a mixer 1, a pulverizing hoist 3, a centrifugal air separator 4, an air preheater 11 and an air heater 12, and the wet fermented feed feed pipe G1 and the mixer 1 The feed port of the mixer 1 is connected to the inlet of the feeder 2, the outlet of the feeder 2 is connected to the crushed new material inlet 3e of the crushing lift 3, and the crushing lift 3 The pulverizing discharge port 3g is connected with the inlet of the fermented feed drying pipe G2, the outlet of the fermented feed drying pipe G2 is connected with the wind separator feed port 4b1 of the centrifugal air separator 4, and the wind separator of the centrifugal air separator 4 The air inlet 4a1 is connected with the hot air pipeline G3, and the air separator wet material outlet 4a2 of the centrifugal air separator 4 is connected with the crushing feed inlet 3f of the crushing elevator through t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap