Water-driven filtering and reverse cleaning device for micro irrigation and filtering and reverse cleaning method

A water-driven, back-cleaning technology, applied in the directions of loose filter material filters, filtration separation, separation methods, etc., to achieve the effects of small head loss, safe and reliable work, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

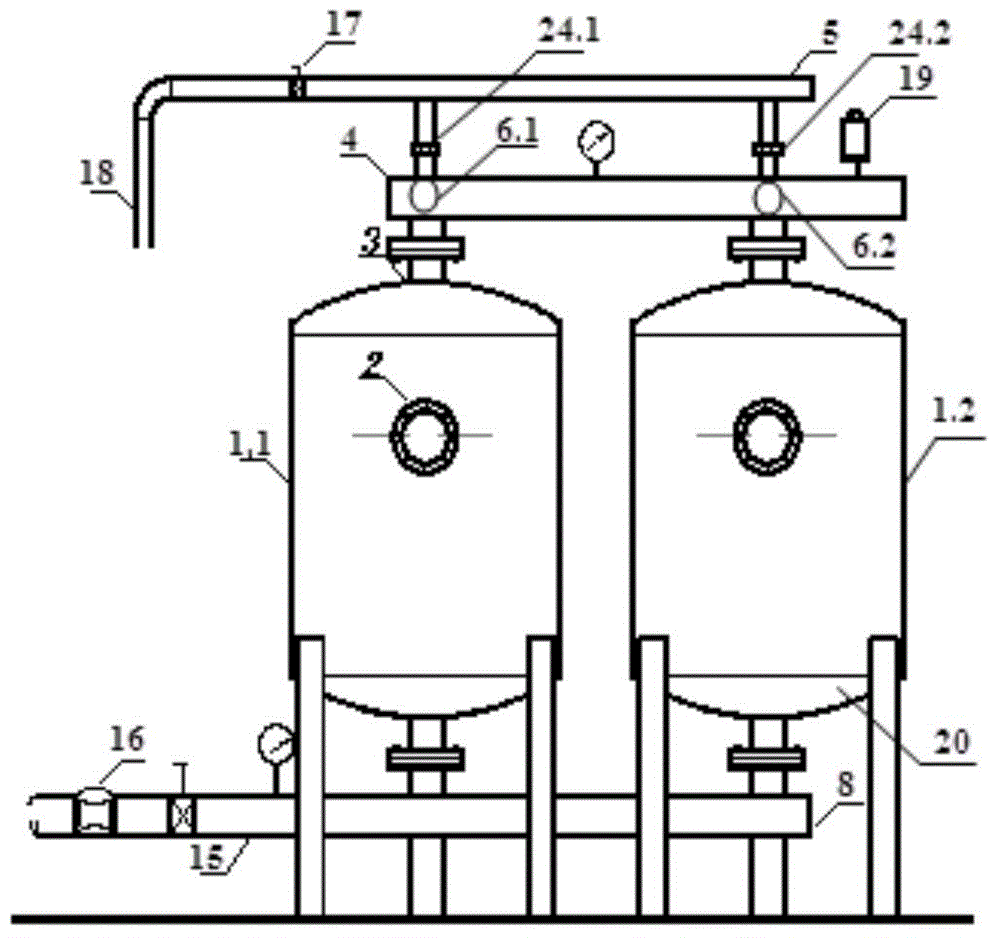

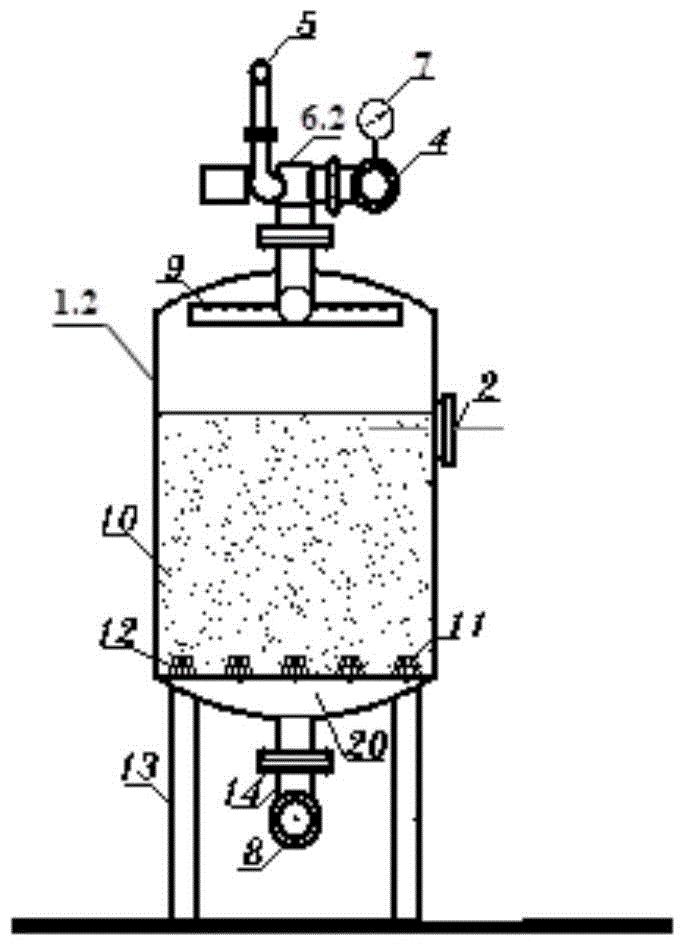

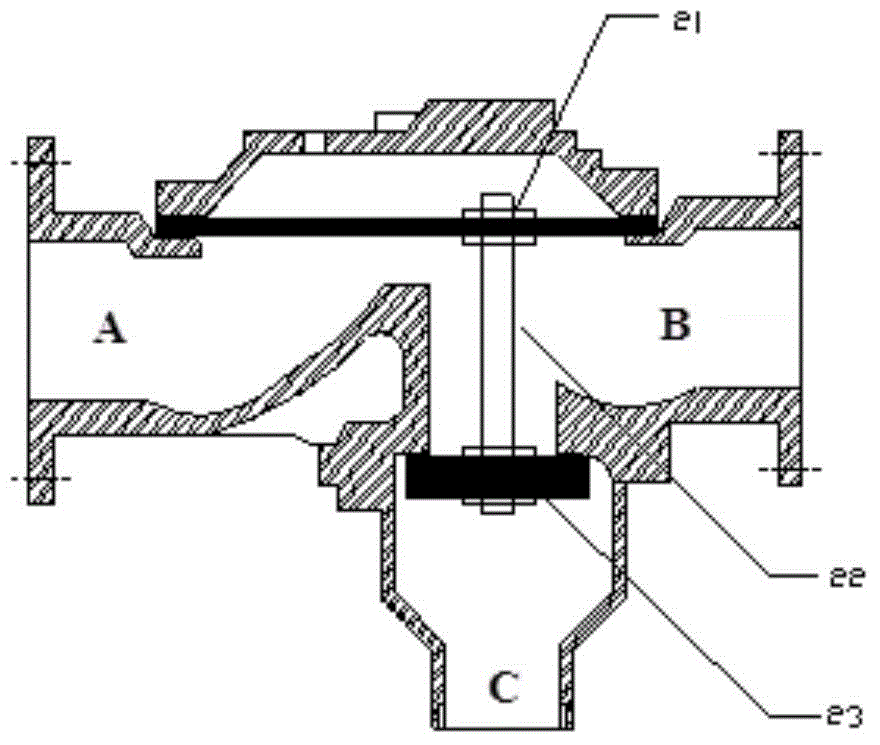

[0028] The invention provides a micro-irrigation water-driven filtration and backwashing device, referring to figure 1 , figure 2 and image 3 , including a tank body with a water inlet 3 at the top and a water outlet 14 at the bottom, a water inlet pipe 4 and a water outlet pipe 8. There are two tank bodies, namely tank body I1.1 and tank body II1.2, and tank body I It is installed on a pair of supporting legs 13 in parallel with tank body II. Both the water outlets of the tank body I and the tank body II are connected with the water outlet pipe, and the water outlet pipe is provided with a master control valve 15; the inside of the tank body I and the tank body II are divided into two upper and lower cavities by the support plate 12, and the support plate Laminated water filter caps 11 are evenly arranged on the top, the size of the launders on the laminations is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com