Portable Automatic Girth Welding Machine

A girth seam welding machine and portable technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing factory production costs, restricting production efficiency and production quality, and excessive human factors. , to achieve the effect of reducing labor intensity, light weight and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

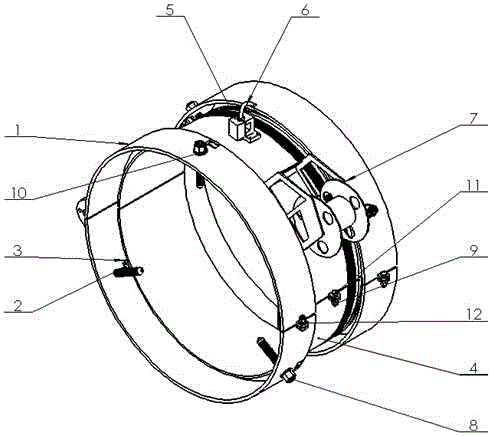

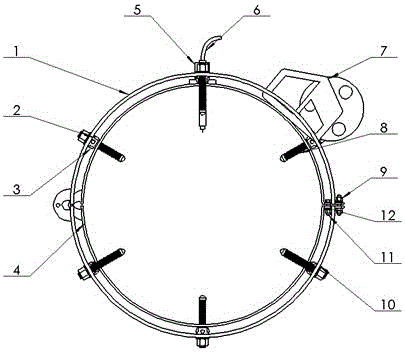

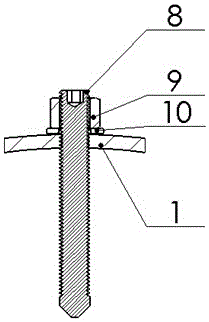

[0020] Such as Figure 1 to Figure 3 As shown, the portable automatic girth welding machine mainly includes: welding machine fixed ring 1, rolling wheel seat 2, rolling wheel 3, welding machine rotating ring 4, welding torch clamp 5, welding torch 6, wire feeder 7, inner hexagon Tapered end set screw 8, nut 9, flat washer 10, bolt 11, spring washer 12, etc.

[0021] The welding machine fixed ring 1 and the welding machine rotating ring 4 are rotatably connected through the rolling wheel seat 2 and the rolling wheel 3. The welding machine fixed ring 1 is provided with hexagonal cone end set screws 8 at a distance of 120 degrees, which are used for three-point contact to make the pipe fittings completely The constraint is fixed; the welding machine rotating ring 4 is provided with tooth slots, and the welding machine rotating ring 4 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com