Rolling separation device for pcb board automatic sorting machine

An automatic sorting and separation device technology, applied in the field of mechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

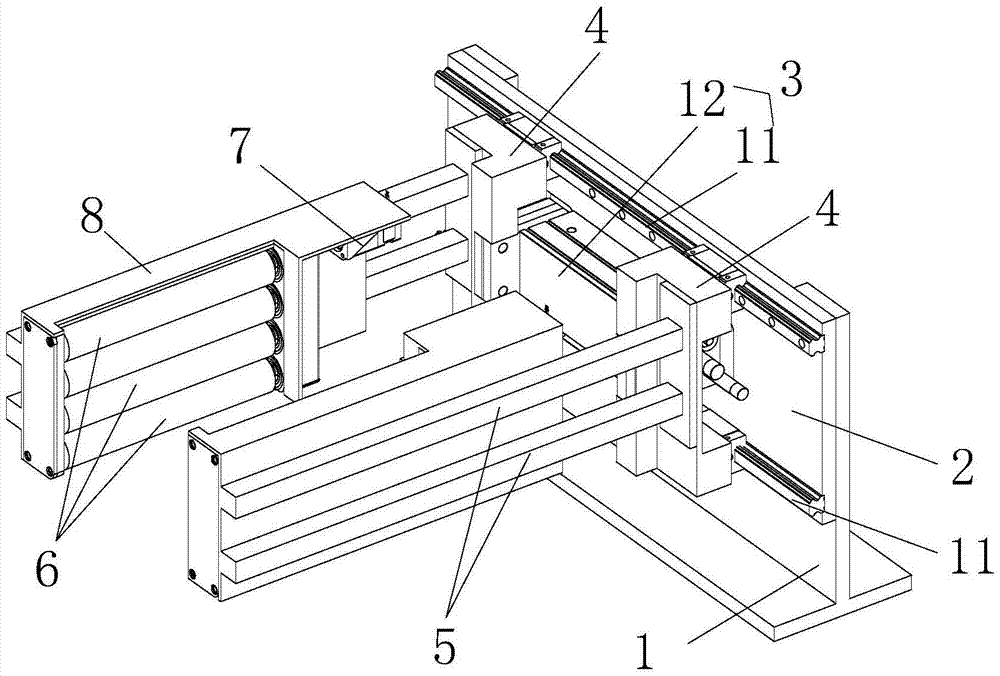

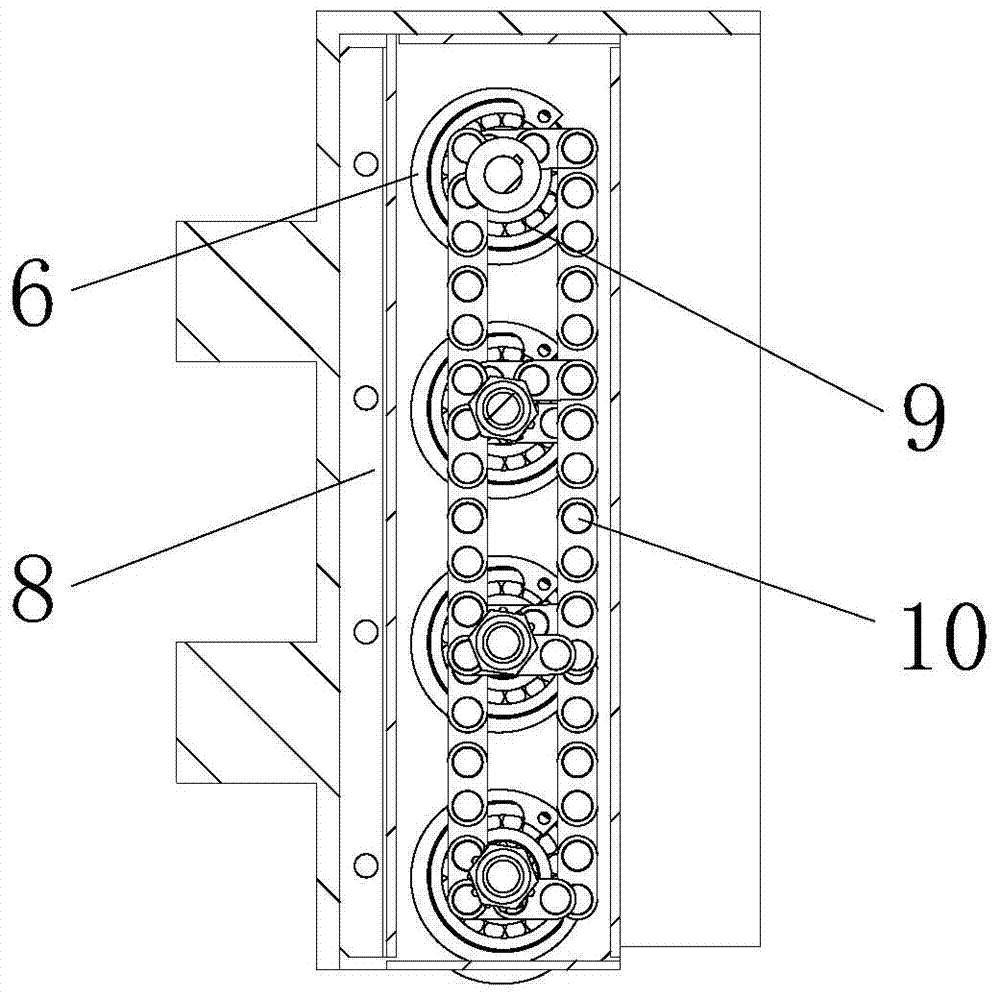

[0016] Embodiment of the present invention: a kind of rolling separation device for PCB board automatic sorting machine, such as figure 1 As shown, it includes a base 1, a connecting plate 2, a distance adjustment mechanism 3, a separator fixing seat 4, a separator connecting rod 5, a separation roller 6 and a drive motor 7, the connecting plate 2 is fixed on the base 1, and the distance adjustment mechanism 3 is set On the board surface of the connecting plate 2, two separator fixing seats 4 are installed on the distance adjustment mechanism 3 and are slidably connected with it. The two separator fixing seats 4 are respectively provided with a separator connecting rod 5 and two sets of separation rollers. 6 are respectively fixed on the separator connecting rod 5 through the separation roller mounting shell 8; the two separation roller mounting shells ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com