Automatic folding type flap gate of construction lifter

A technology for construction elevators and flap doors, which is applied in the field of elevators, can solve the problems that the flap doors cannot be opened normally, and the cage cannot be completely closed, so as to achieve the effects of guaranteed component strength, simple structure, and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

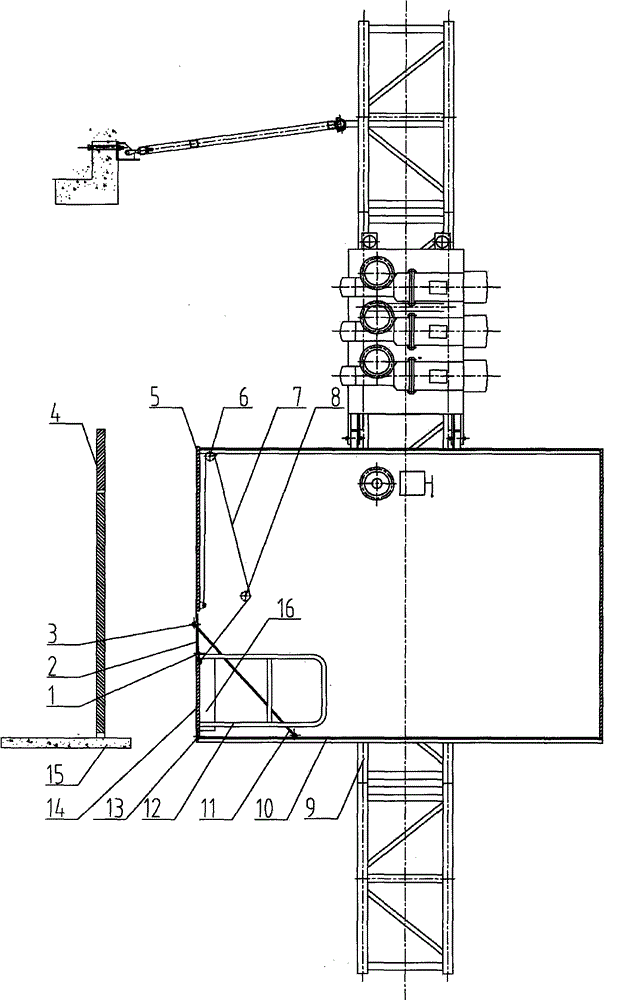

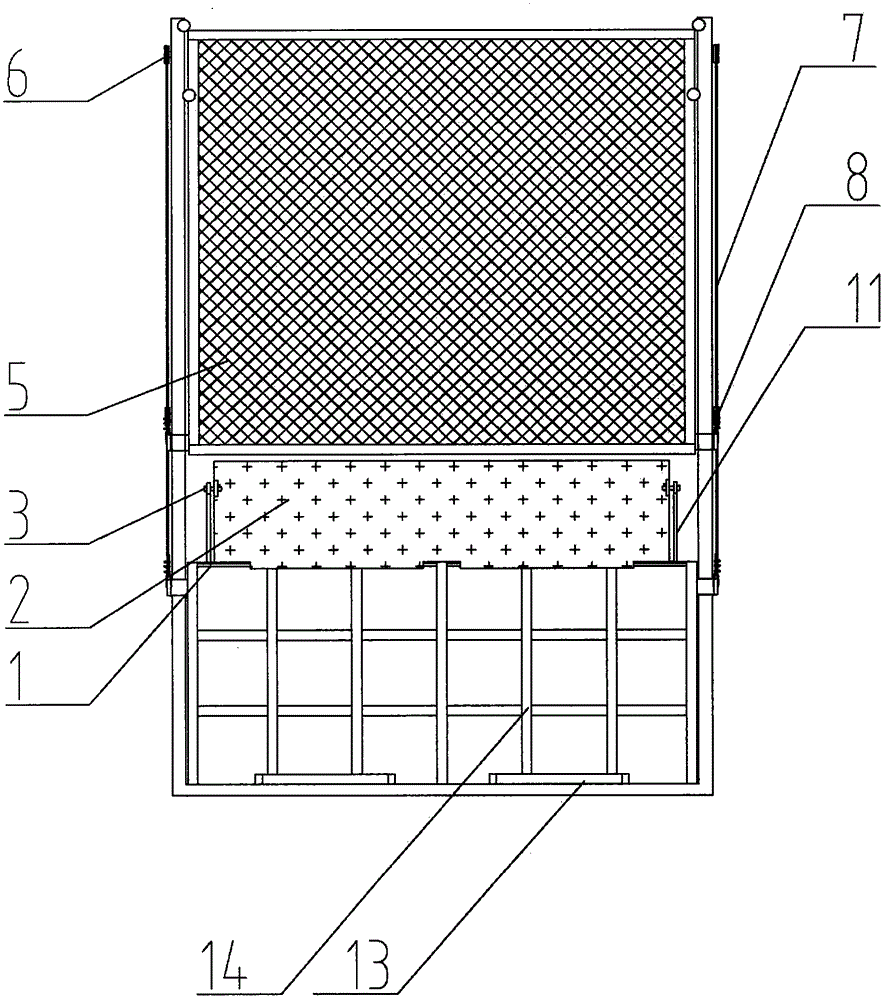

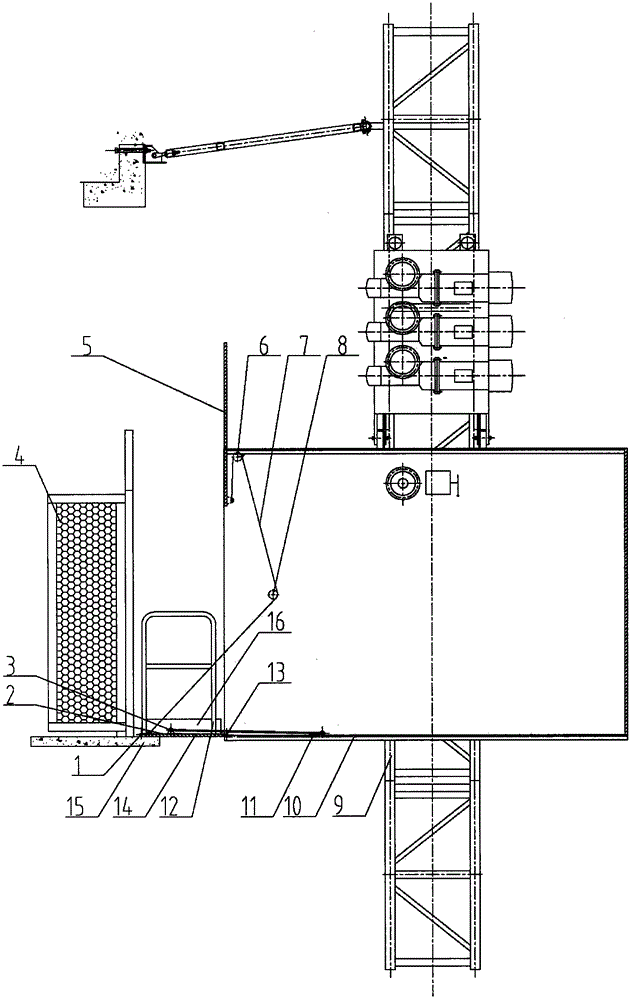

[0020] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is an automatic folding flap door of a construction elevator, which is installed on one side of a hanging cage 10. The hanging cage 10 is arranged on a guide rail frame 9 and can be lifted up and down along the guide rail frame 9.

[0021] The automatic folding flap door of the construction elevator of the present invention is composed of lower flap door 14, upper sliding door 5, folding baffle plate 2, connecting rod 11, steel wire rope 7, upper fixed pulley 6, lower fixed pulley 8 and connecting rod 11 etc. Partial composition.

[0022] Wherein, the lower flap door 14 is pivotally connected to the bottom of the cage 10 through a flap door shaft 13 . The upper sliding door 5 is installed on the top of the cage 10 and can be lifted and lowered along the cage 10 . The folding baffle 2 is pivotally connected to the top of the lower flap door 14 through a folding baffle shaft 1 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com