Fireproof composite board with vacuum insulation and decoration functions and preparation method of composite board

A technology of vacuum insulation and thermal insulation boards, which is applied in covering/lining, construction, building construction, etc. It can solve the problems of high thermal conductivity and reduced flame retardancy of integrated boards, so as to improve its own strength and avoid hollowing and cracking , The effect of eliminating thermal bridge problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings.

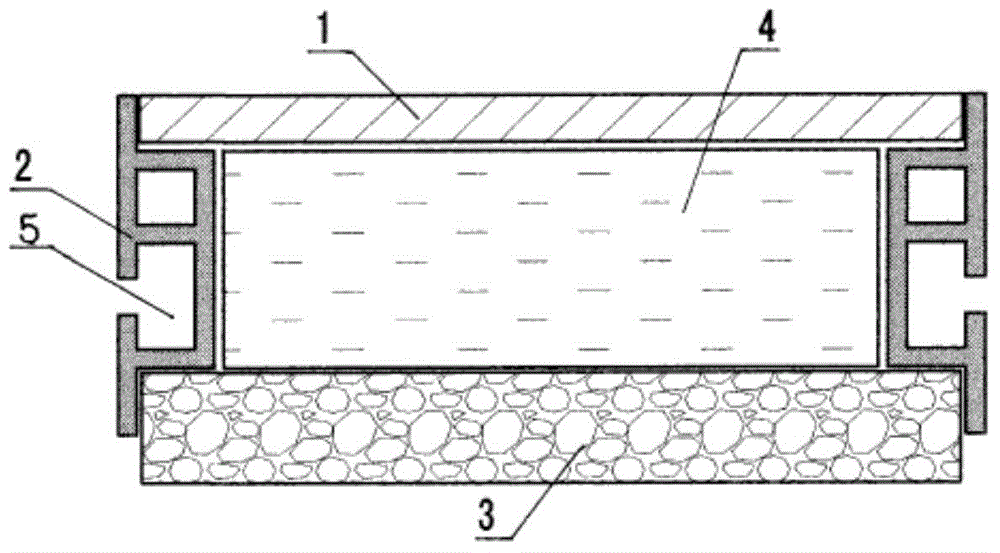

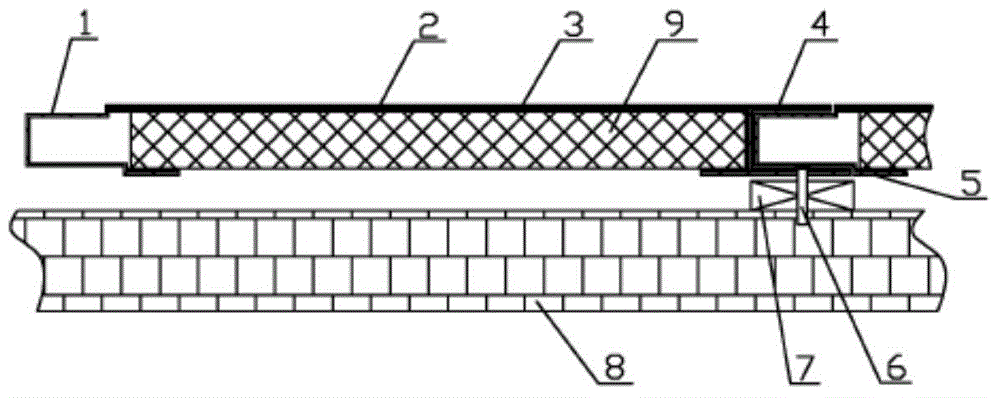

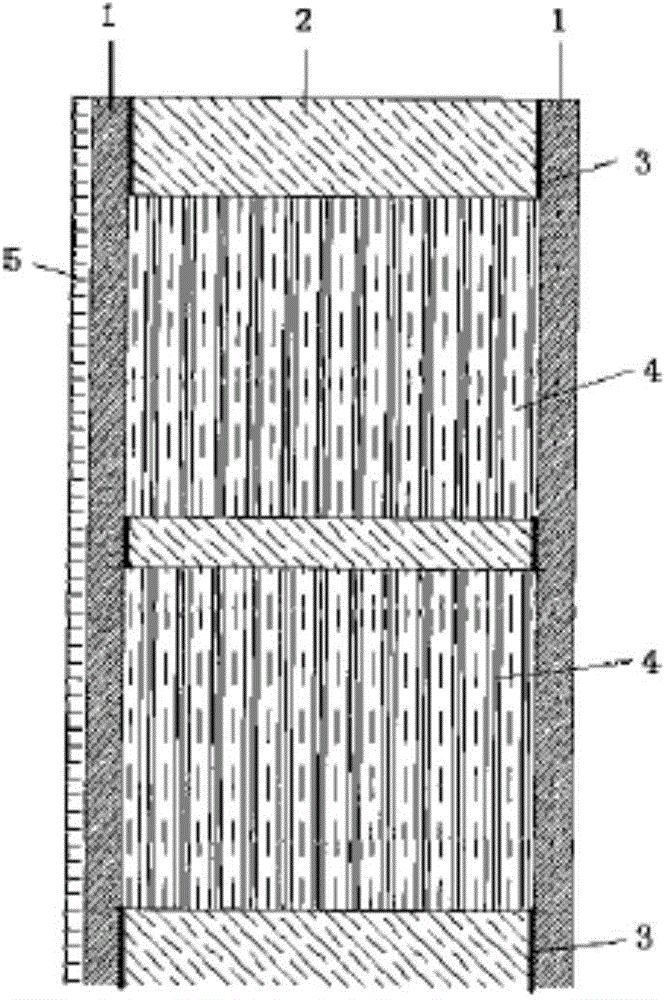

[0043] Such as Figure 4As shown, the present invention discloses a fireproof vacuum insulation decorative composite board, which includes a decorative panel 1 , a thermal insulation board 2 , a protective frame 5 , a first protective layer 3 and a second protective layer 4 . Wherein, the heat preservation board 2 is co-embedded in the protection frame 5, that is, the protection frame 5 is socketed with the outer edge of the heat preservation board 2 to tightly hold the heat preservation board 2, so that the protection frame 5 can protect the heat preservation board 2 to the greatest extent. corners and perimeters. The thickness of the heat preservation board 2 in this embodiment is consistent with the height of the framework of the protection frame 5, so that both sides of the heat preservation board 2 do not protrude from the protection frame 5 after the heat pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com