A preheating mixing device and method for blending alcohol-based fuel into natural gas

A technology of alcohol-based fuel and mixing device, which is applied in the direction of fuel heating of turbine/propulsion device, turbine/propulsion fuel delivery system, charging system, etc., to achieve the effect of ensuring uniformity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Preheating mixing device and method for blending alcohol-based fuel into natural gas

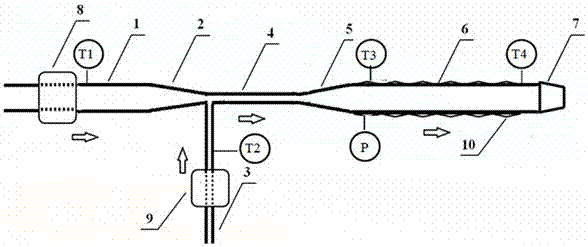

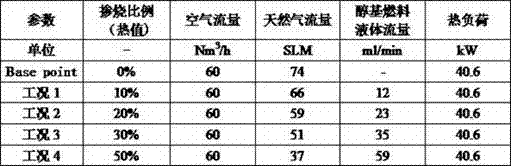

[0022] Such as figure 1 , a device for blending alcohol-based fuel into natural gas, comprising a fuel pipeline, a heating unit, a temperature measurement unit and a pressure measurement unit; the fuel pipeline sequentially includes a natural gas pipeline section 1, a contraction section 2, a high-speed mixing section 4, The expansion section 5, the low-speed mixing section 6 and the nozzle 7, the high-speed mixing section 4 near the constriction section 2 are branched with an alcohol-based fuel pipeline section 3; The oil bath heating device 9 of the fuel pipeline section and the electric heating sheet 10 arranged in the low-speed mixing section, the heating sheet 10 is wrapped on the pipeline; The first thermometer T1 between them, the second thermometer T2 located between the second heater 9 and the high-speed mixing section 4 on the alcohol-based fuel pipeline section ...

Embodiment 2

[0027] Example 2: The influence of the inner diameter ratio of the natural gas pipeline section and the high-speed mixing section on the uniformity of mixed gas

[0028] The OH* (OH autofluorescence) distribution can reflect the heat release intensity of the flame. Natural gas mixed with different proportions of alcohol-based fuels has different heat release intensity during combustion, so the OH* distribution is also different. The test of OH* distribution is obtained with ICCD (enhanced CCD) camera combined with BP308 / 10 narrow-band filter. The distribution of OH* in the flames of natural gas mixed with different proportions of alcohol-based fuels is different. The difference reflected is that the color distribution on the photos obtained by ICCD is different, which means that the flame heat release intensity in different regions is different. Therefore, if natural gas and alcohol-based fuel are blended uniformly, the color distribution of multiple photos obtained within a ...

Embodiment 3

[0030] Example 3: Effect of the ratio of length and inner diameter of the high-speed mixing section on the uniformity of mixed gas

[0031] In Example 1, the inner diameter of the high-speed mixing section is 3 mm, the length is 500 mm, and the length is about 167 times the inner diameter. In order to study the effect of the ratio of the length and inner diameter of the high-speed mixing section on the uniformity of the mixed gas, four other devices with different ratios were designed. The inner diameter of the high-speed mixing section is 3mm, and the lengths are: 420mm (ratio of length to inner diameter is 140:1), 450mm (ratio of length to inner diameter is 150:1), 540mm (ratio of length to inner diameter is 180:1) ) and 570mm (the ratio of length to inner diameter is 190:1), and the other pipe dimensions are the same as in Example 1. Use these 5 devices to blend alcohol-based fuel into natural gas according to the blending method in Example 1 (the blending ratio is 50%, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com