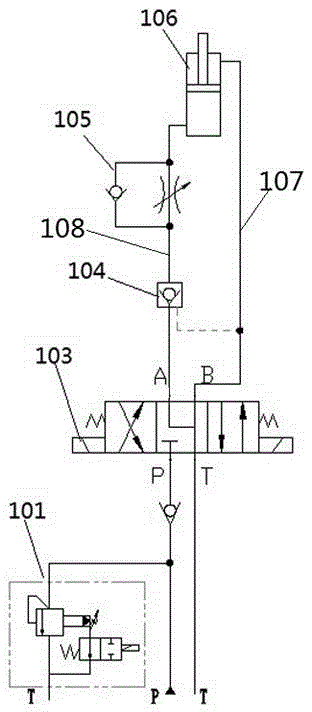

Piston lifting mechanism and hydraulic control device thereof

A lifting mechanism and control device technology, applied in the direction of fluid pressure actuating device, mechanical equipment, servo motor, etc., can solve the problem of easy vibration of the piston, and achieve the effect of avoiding the vibration of the piston when moving, reducing the impact and improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

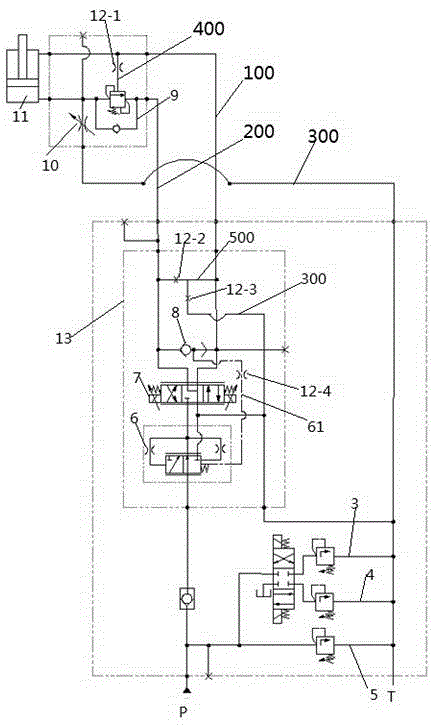

[0024] Such as figure 2 Shown, a kind of embodiment of piston elevating mechanism, the piston elevating mechanism in this embodiment comprises piston cylinder 11, is connected with piston rod on the piston of piston cylinder 11, and the inner chamber of piston cylinder 11 is divided into rod cavity and chamber by piston. The rodless chamber also includes a hydraulic control device for driving the piston to reciprocate. The hydraulic control device includes a first oil circuit 100 corresponding to the rod chamber of the piston cylinder 11 and a first oil passage 100 communicated with the rodless chamber of the piston cylinder 11. The second oil passage 200, where the first oil passage and the second oil passage communicate with the speed compensation module 13, where the two working ports of the proportional reversing valve 7 in the speed compensation module 13 are respectively connected to the first oil passage The oil passage 100 and the second oil passage 200 communicate, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com