Shear fork-type ejection mechanism

A jacking mechanism, scissors and forks technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of poor stability, and achieve the effects of easy maintenance and assembly, good lifting stability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

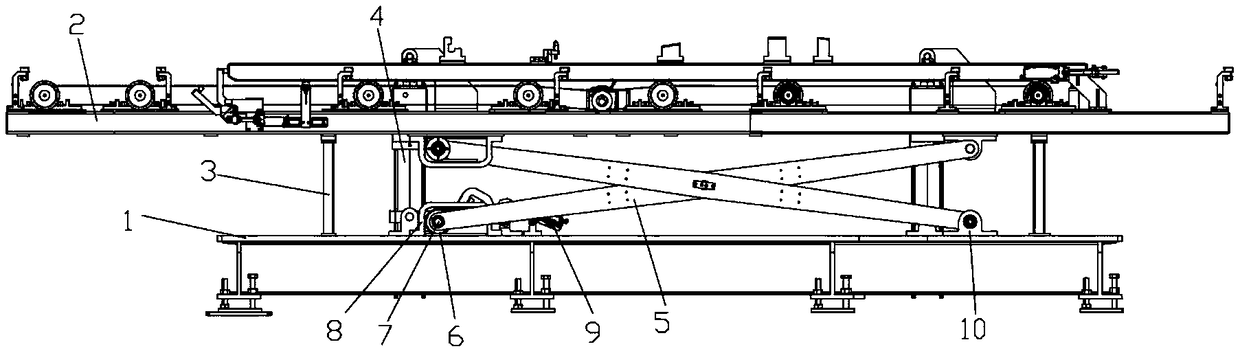

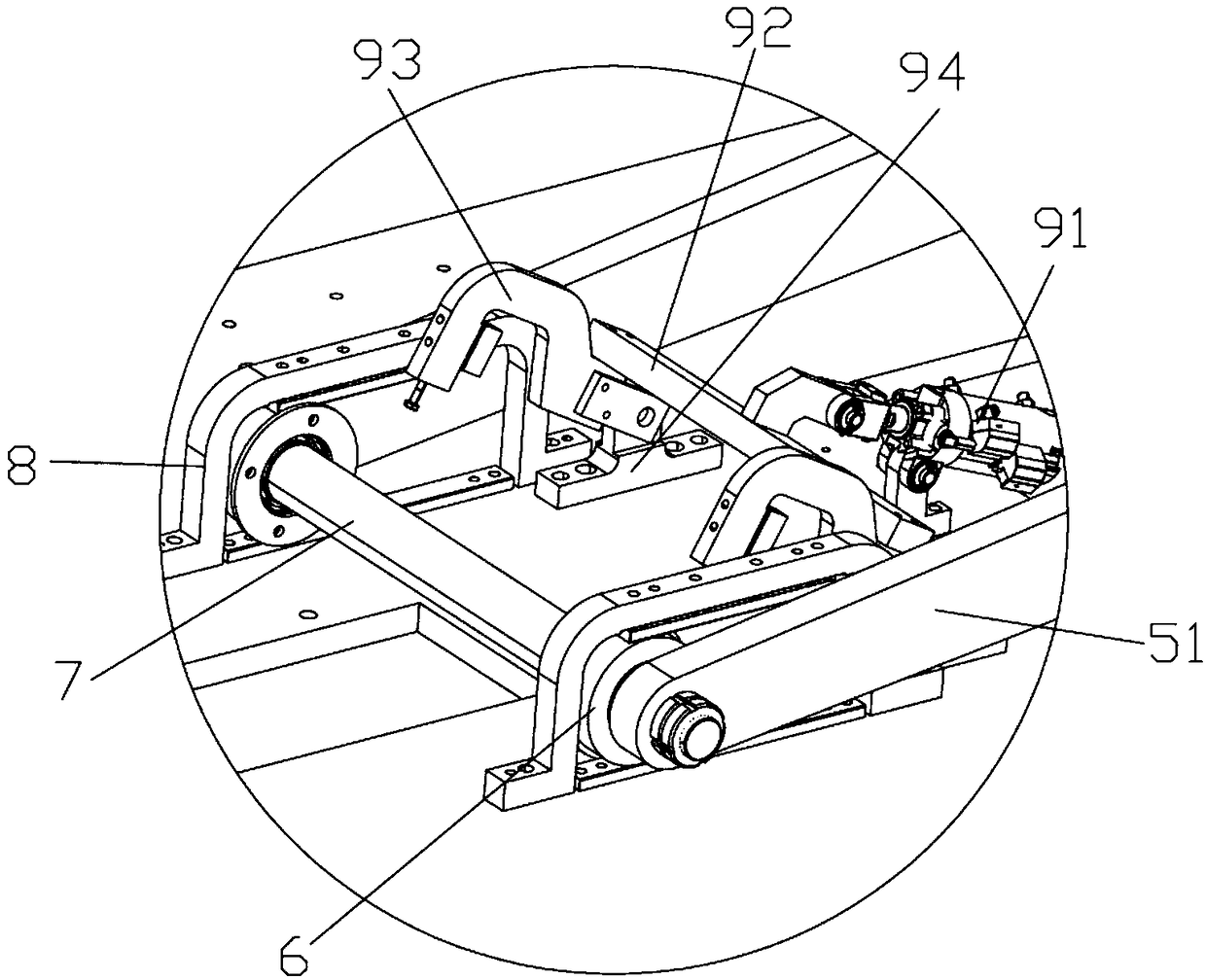

[0021] This scissors fork type jacking mechanism of the present invention, as figure 1 As shown, it includes the base 1, and also includes the jacking frame 2 set above the base 1 driven by the lifting cylinder 4. 5.

[0022] Such as figure 1 As shown in , one side of the scissors and fork assembly 5 is a fixed end, and one side is a sliding end. The upper end and the lower end of the fixed end of the scissor-fork assembly 5 are respectively hinged on the jacking frame 2 and the base 1 through the hinge seat 10;

[0023] In the present invention, the scissor fork assembly 5 includes two cross-connected jacking rods 51, and the two jacking rods 51 are rotatably connected by a pin shaft to form a scissor-shaped cross-connected structure. Stability during the process, stably supporting the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com