Cabinet system wind resistance test method

A test method and technology for cabinets, applied in the field of cabinets, can solve the problems of over-temperature, long time-consuming, and over-temperature faults of the whole machine, and achieve the effect of solving fan selection, easy operation and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

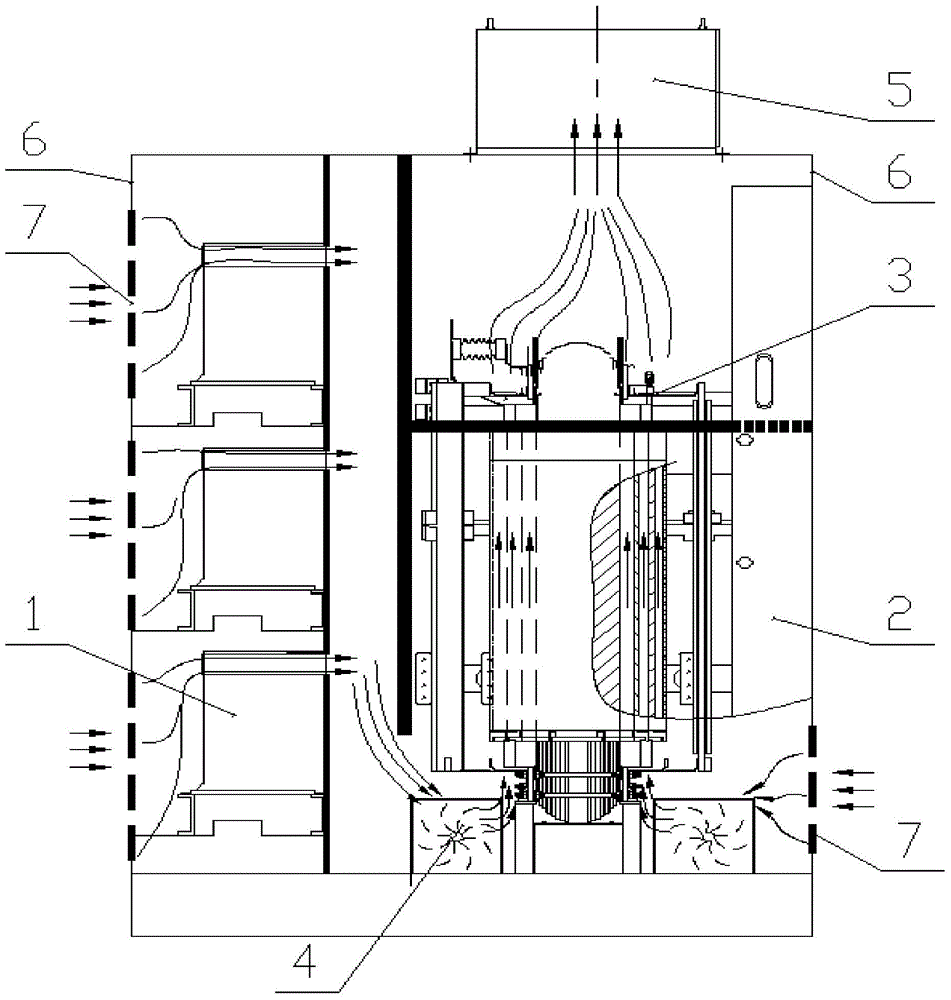

[0034] Such as figure 1 with figure 2 As shown, the method for testing the air resistance of the cabinet system in this embodiment, the method steps of the present invention are as follows:

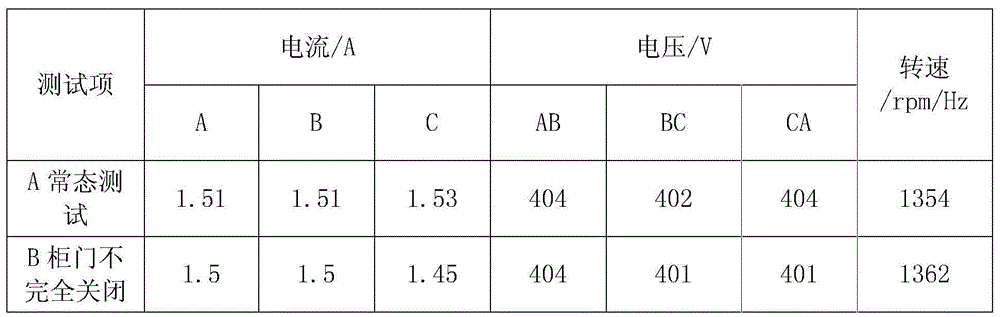

[0035] S1: When the cabinet is powered on and running, measure the operating parameters of the exhaust components of the cabinet under the two working conditions of opening and closing the cabinet door;

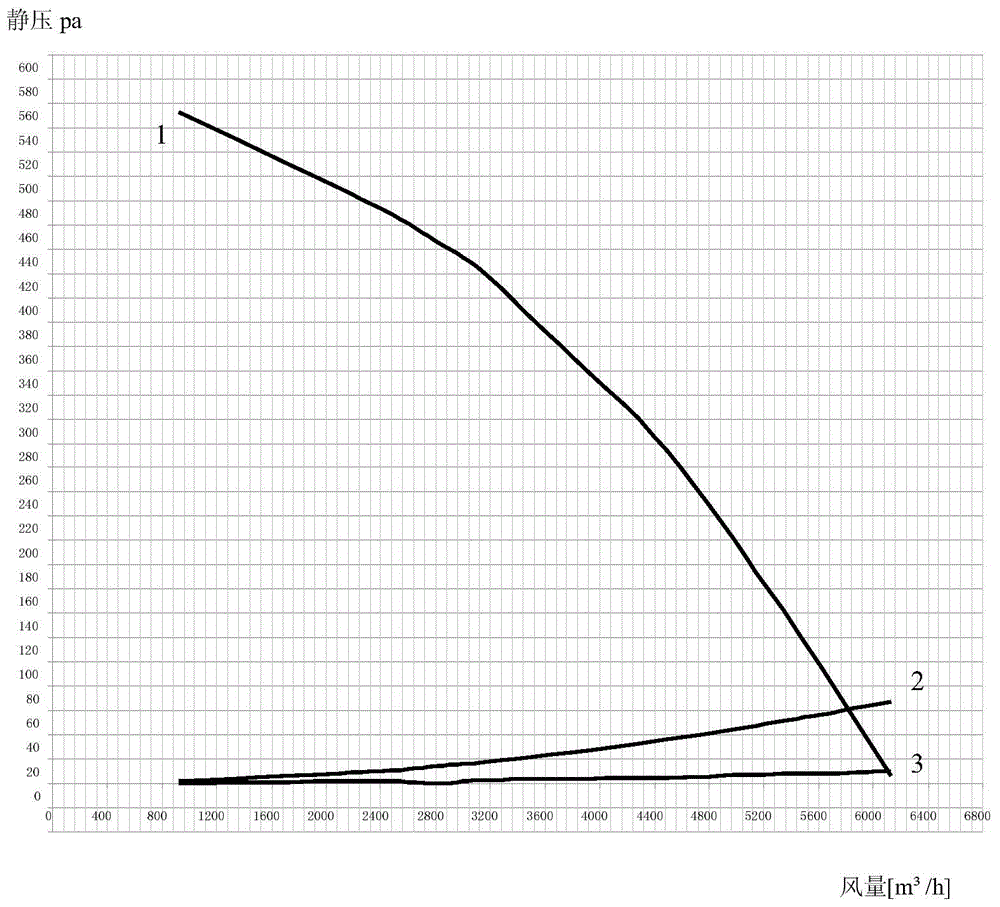

[0036] S2: Comparing and analyzing the operating parameters of the exhaust assembly under the two working conditions in step S1 and the factory test data of the exhaust assembly, and obtaining the corresponding air volume Q and static pressure P of the exhaust assembly under the condition of closing the cabinet door, thereby Calculate the resistance coefficient K=P / Q of the cabinet system 2 ;

[0037] S3: Through the resistance coefficient K of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com