Mechanical failure monitoring system and method

A technology of mechanical fault and monitoring system, applied in the field of monitoring, can solve the problems of high power consumption, inability to monitor and analyze various mechanical faults, large equipment size, etc., achieve large frequency bandwidth, get rid of the dependence of CPU processing capacity, and achieve synchronization The effect of analysis and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

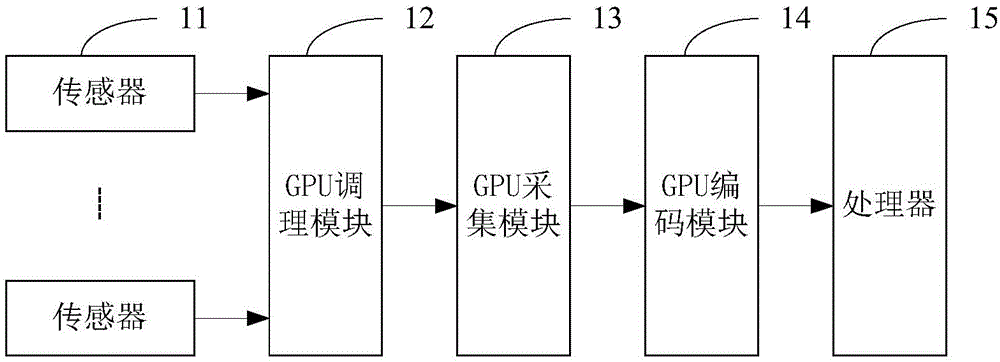

[0042] figure 1 The composition structure of the mechanical fault monitoring system provided by Embodiment 1 of the present invention is shown, and for the convenience of description, only the parts related to the present invention are shown.

[0043] In this embodiment, the low processing capability of the micro-x86 platform CPU is compensated by the GPGPU technology of the general-purpose computing image processor, and a multi-channel miniaturized mechanical fault monitoring system based on GPGPU is provided.

[0044] Such as figure 1 As shown, the mechanical failure monitoring system includes:

[0045] A plurality of sensors 11 are used to respectively detect operating parameters of mechanical equipment to obtain multi-channel operating parameters, and send the multi-channel operating parameters to the GPU conditioning module.

[0046] In this embodiment, the multiple sensors respectively detect operating parameters such as rotational speed, noise, displacement, and vibra...

Embodiment 2

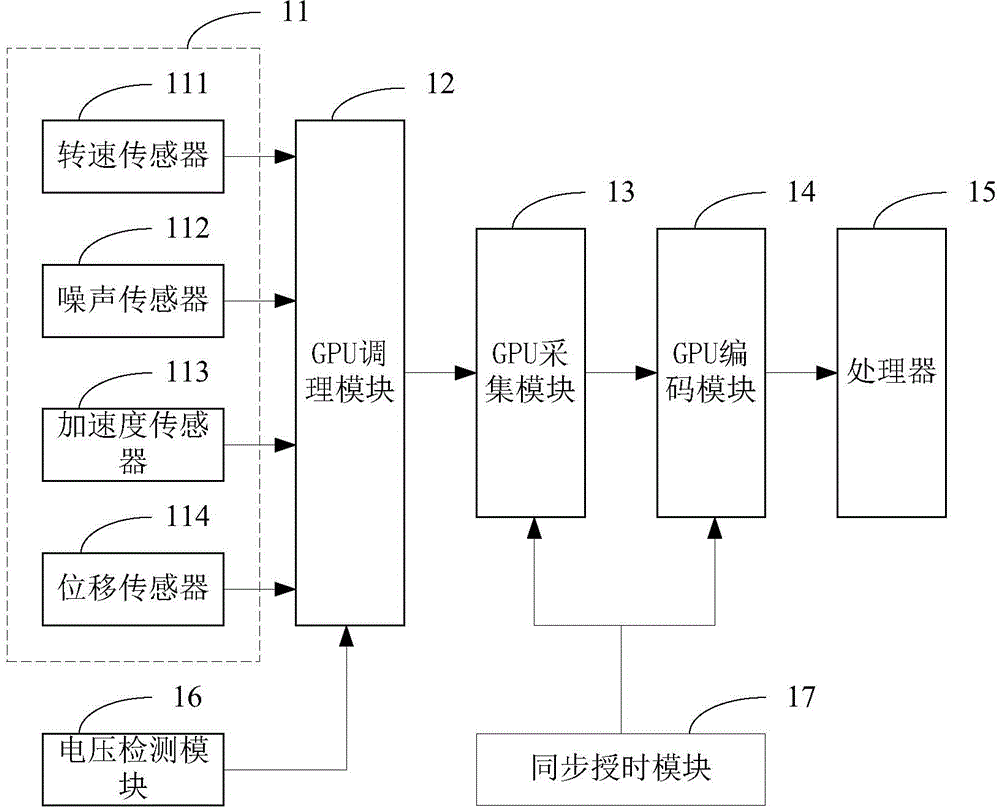

[0063] figure 2 The composition structure of the mechanical fault monitoring system provided by Embodiment 2 of the present invention is shown, and for the convenience of description, only the parts related to the present invention are shown.

[0064] Such as figure 2 As shown, the mechanical failure monitoring system includes:

[0065] A plurality of sensors 11 are used to respectively detect the operating parameters of the machine to obtain multi-channel operating parameters, and send the multi-channel operating parameters to the GPU conditioning module.

[0066] In this embodiment, the multiple sensors include a rotational speed sensor 111, a noise sensor 112, a displacement sensor 113, and an acceleration sensor 114 to detect operating parameters such as rotational speed, noise, displacement, and acceleration of the mechanical equipment during operation; Mechanical equipment for rotors or bearings can also detect the speed and axis trajectory of the rotor or shaft. Af...

Embodiment 3

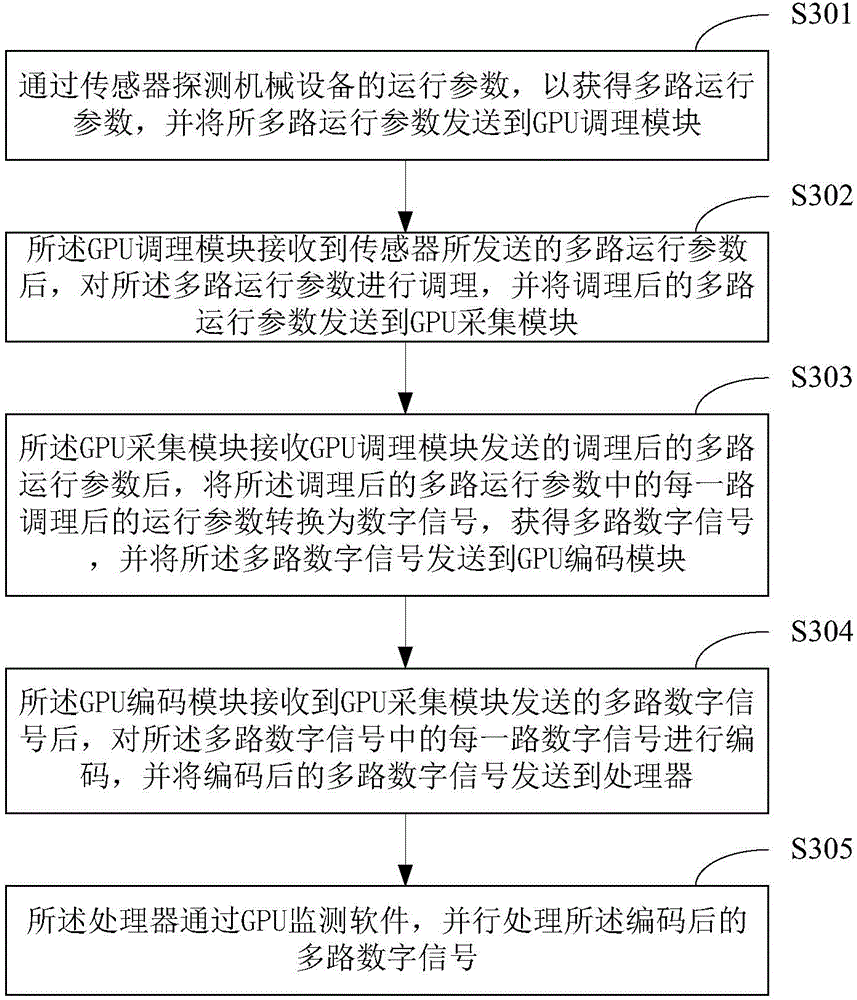

[0085] image 3 The implementation flow of the mechanical failure monitoring method provided by the third embodiment of the present invention is shown.

[0086] The method is applied to figure 1 or figure 2 In the mechanical failure monitoring system described in the embodiment, the system includes a plurality of sensors, a GPU conditioning module, a GPU acquisition module, a GPU encoding module and a processor.

[0087] Such as image 3 As shown, the method includes:

[0088] In step S301, the sensor detects the operating parameters of the mechanical equipment to obtain multiple operating parameters, and sends the multi-channel operating parameters to the GPU conditioning module.

[0089] In this embodiment, the sensors can be speed sensors, noise sensors, displacement sensors and acceleration sensors to detect operating parameters such as speed, noise, displacement and vibration of mechanical equipment during operation; for machines with rotors or bearings The equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com