Shielding ring and shielding assembly using the same

A technology for shielding rings and components, which is applied in the direction of connecting parts to protect grounding/shielding devices, clamping/spring connections, etc., and can solve problems such as loosening and poor connection reliability of shielding structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

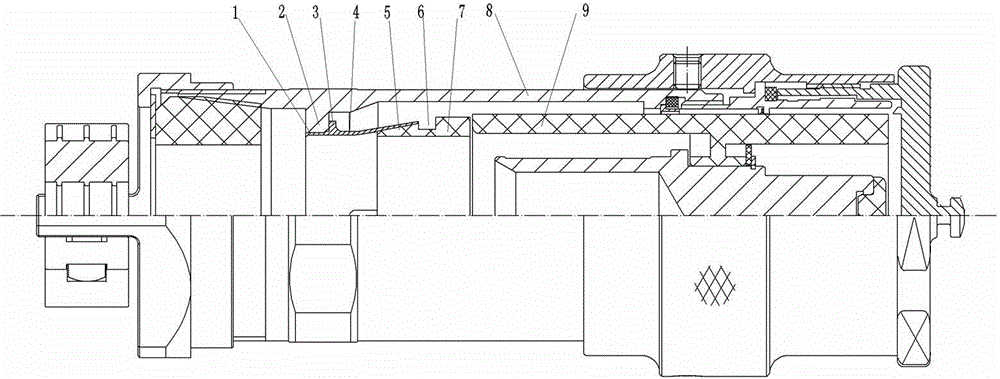

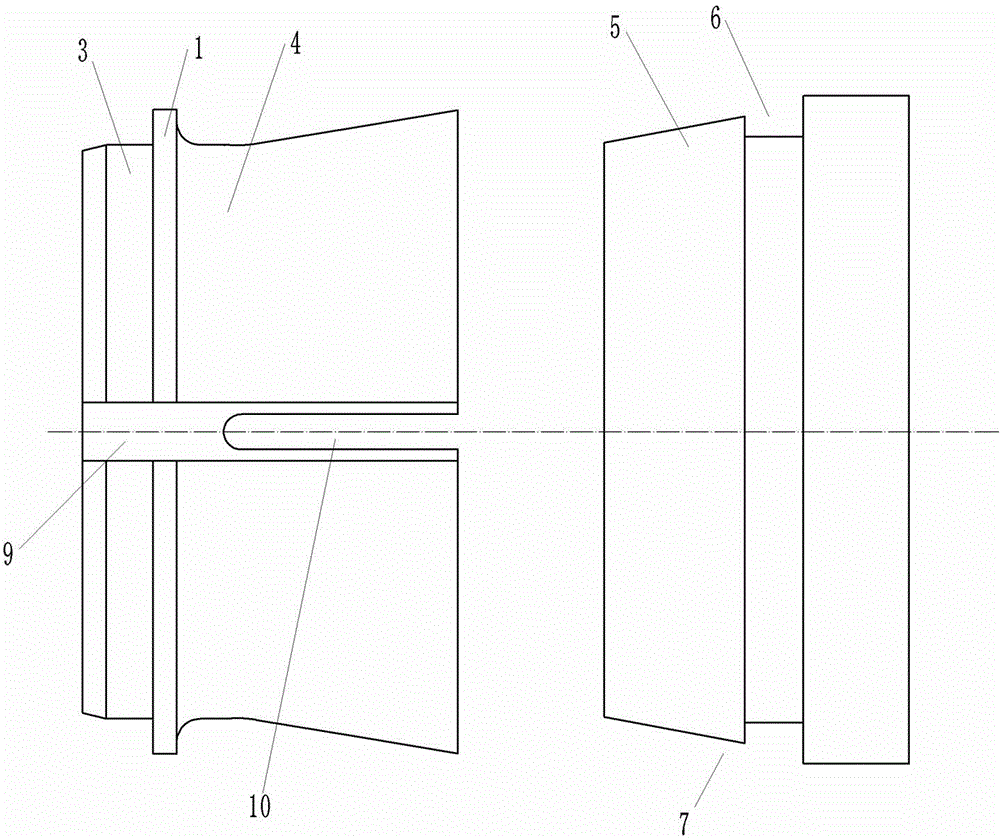

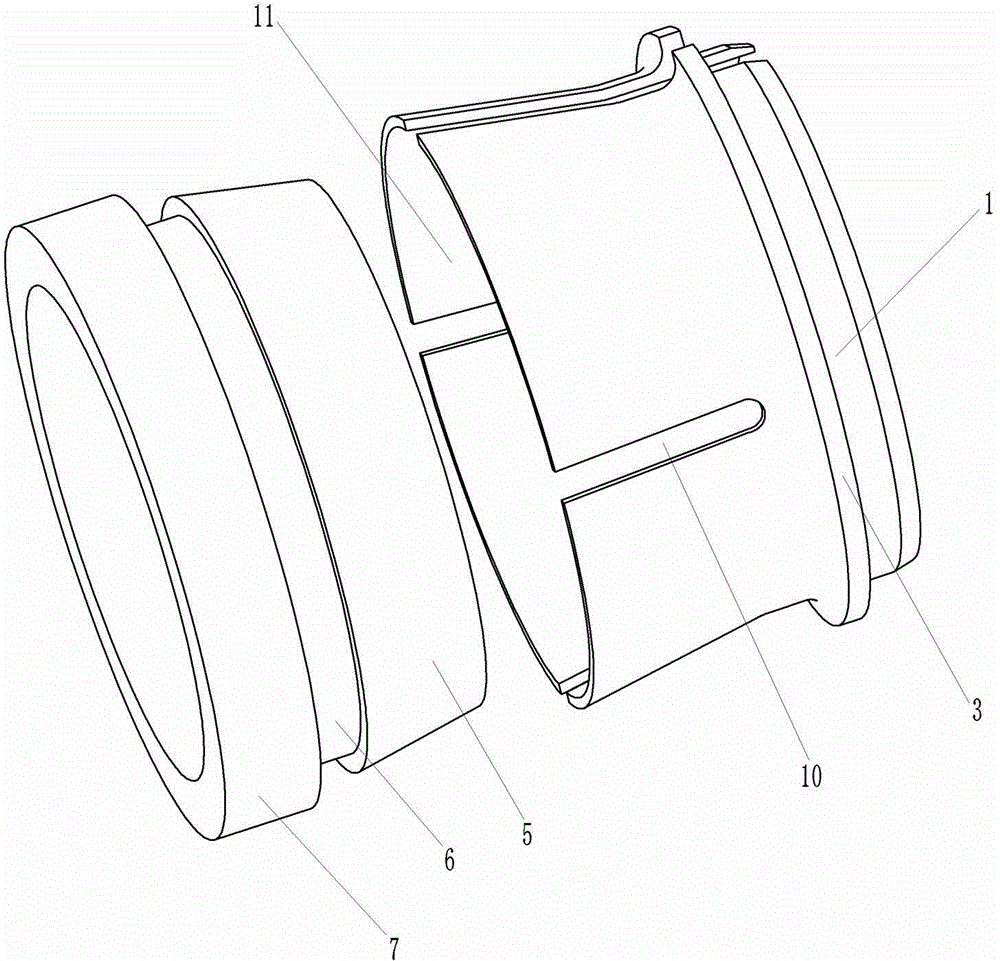

[0019] Examples of shielding components are Figure 1~5 As shown: the shielding ring is used in the electrical connector. The electrical connector includes a housing 8 with a plug-in end at the front end and a shielding assembly arranged in the housing. The shielding assembly includes a shielding ring 4 and a compression ring 7. The shielding ring 4 includes The shielding ring body whose axis is in contact with the housing extends along the front-to-back direction, and the compression ring 7 includes a compression ring body whose axis extends along the front-to-back direction. The hole section 11 is a flaring structure whose diameter gradually increases from the back to the front. In this embodiment, the shielding wire connection hole section 11 is tapered. The front end extending in the direction extends to the crimping deformation groove 10 on the front end surface of the shielding ring body, through the crimping deformation groove, the hole wall of the shielding wire connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com