A two-way drive mechanism

A driving mechanism and two-way driving technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of inconvenient installation of sensors, difficulty in serialization and marketization, complex control, etc., and achieve cost saving, space occupied by motors, and high response speed and control accuracy, the effect of radial rotation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

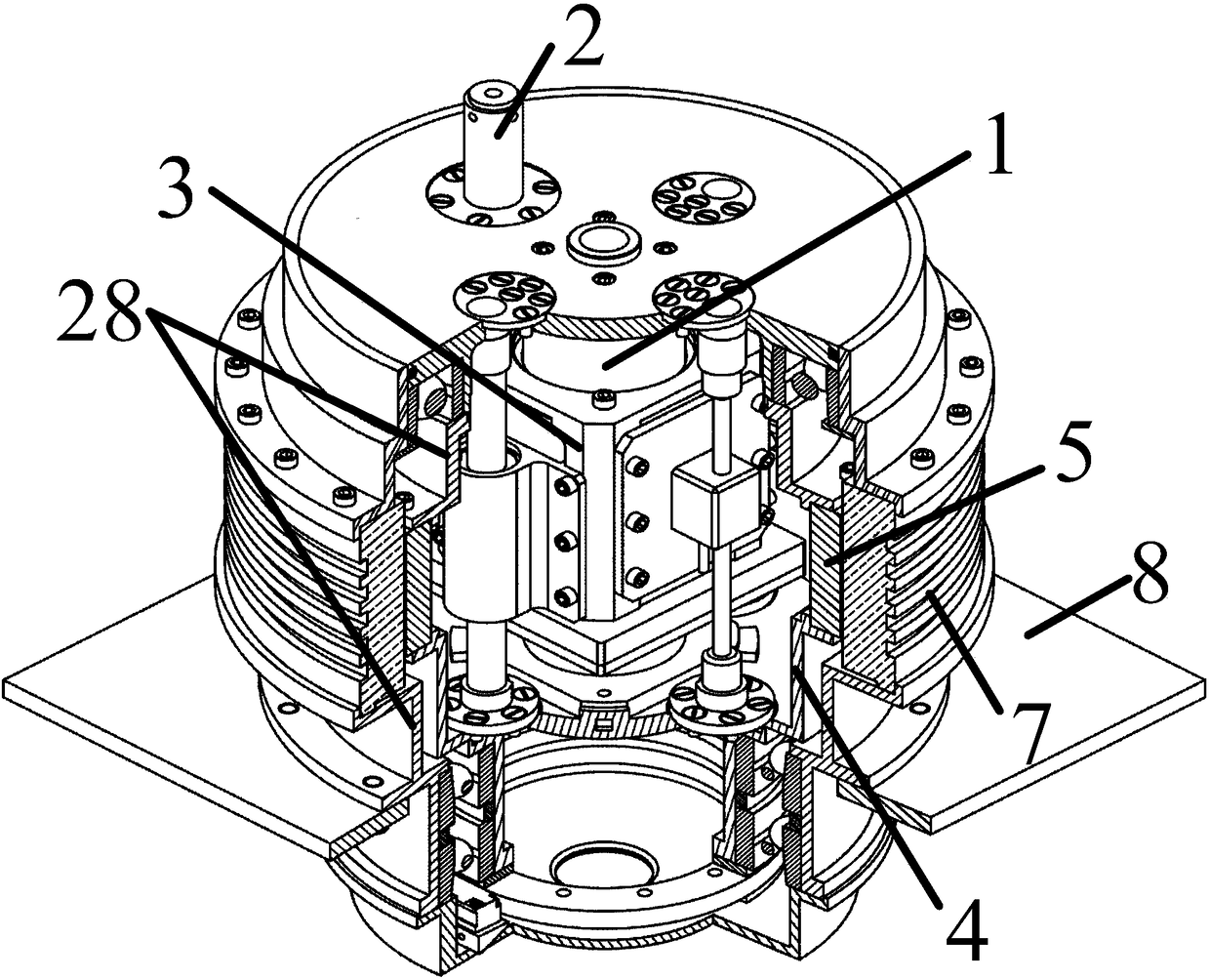

[0040] Such as figure 1 As shown, a bidirectional drive mechanism, the drive mechanism includes a linear motor stator 1 and a push rod 2;

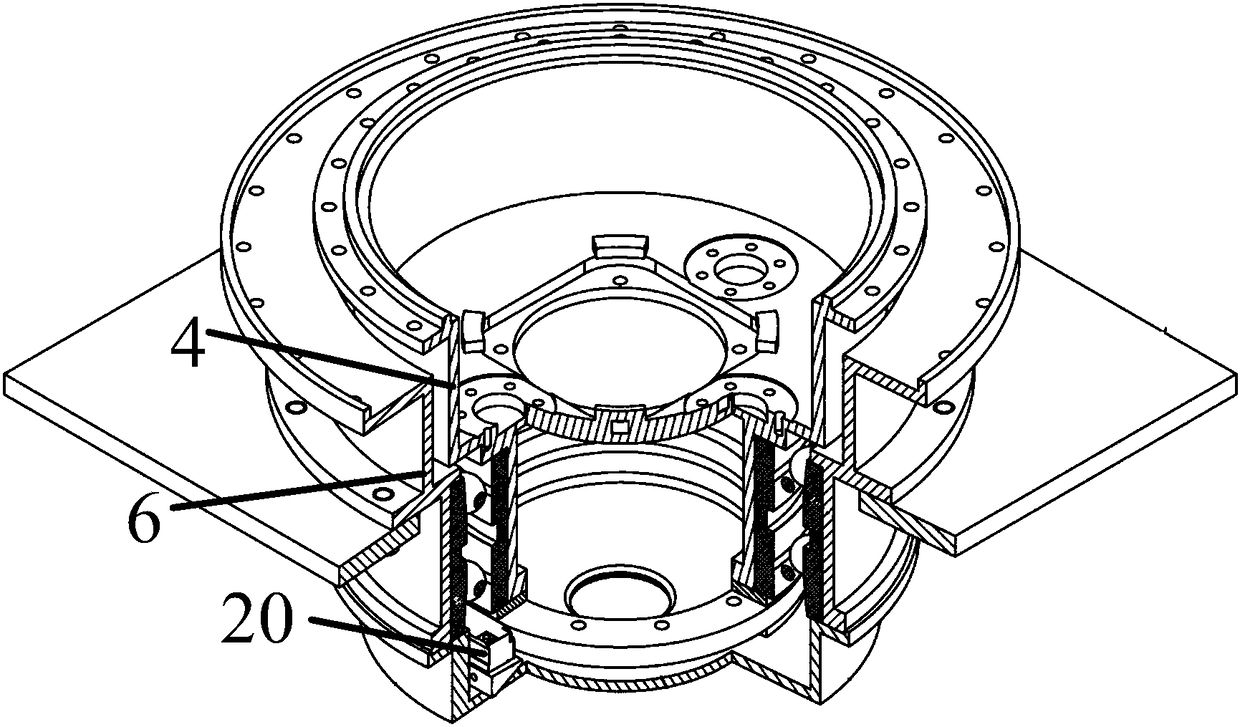

[0041] The drive mechanism also includes a base 8, a movable sleeve 3 arranged outside the linear motor stator 1, a rotary motor rotor 5 and a rotary motor stator 7 with support seats 28 at both ends.

[0042] Such as Figure 4 As shown, the movable sleeve 3 is a cuboid whose lower end is provided with an end cap 9 .

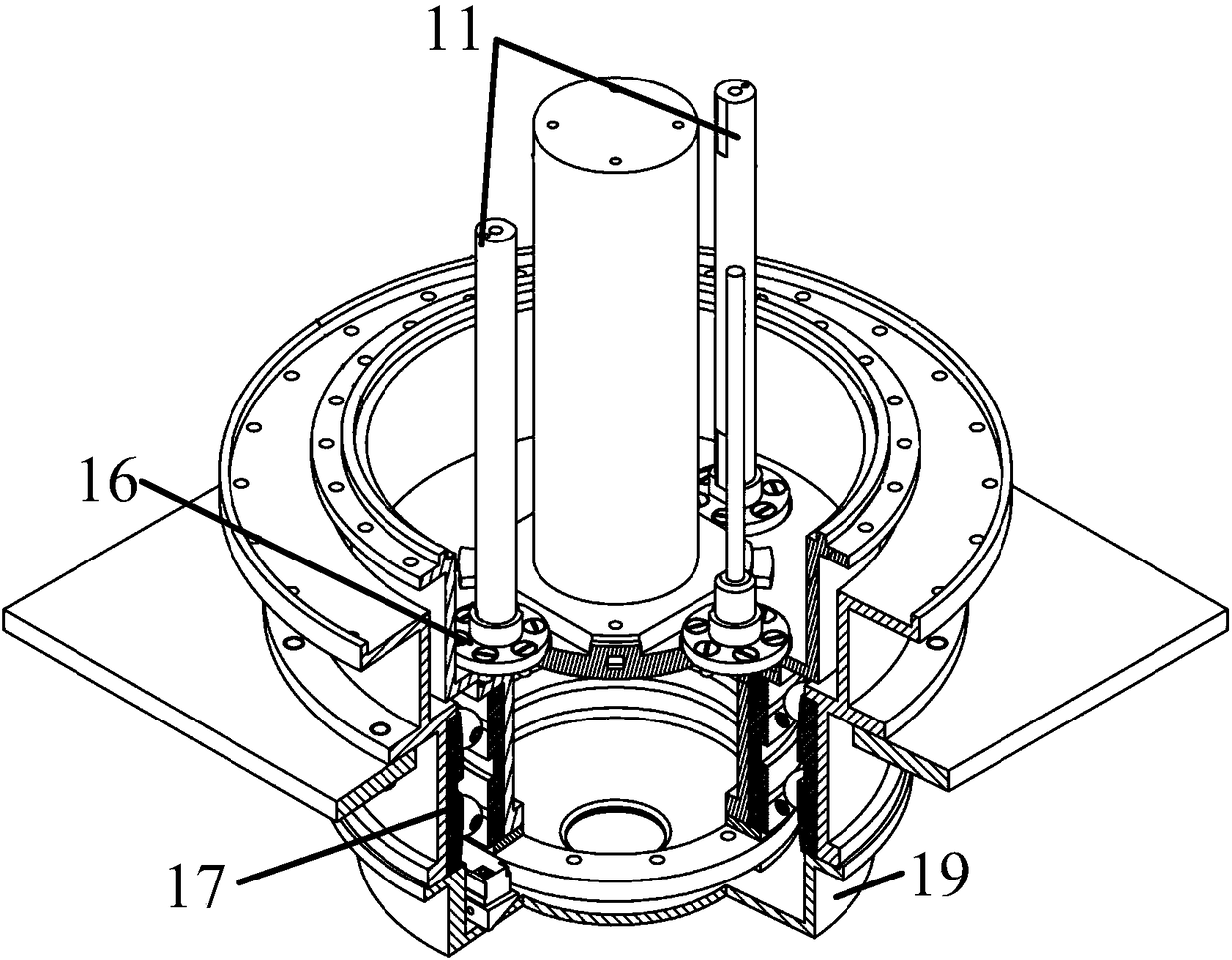

[0043] Such as Figure 5 with Image 6 As shown, bolts are arranged perpendicular to the axial direction of the movable sleeve 3, and the bolts are connected to a fixed plate 10 arranged parallel to the axial direction;

[0044] The fixed plate 10 is two mutually parallel rectangular plates, the surface of which is provided with a fixed sleeve arranged along the axis direction, and a guide rod 11 movably connected with it is provided in the fixed sleeve;

[0045] The bolts arranged on the other two sides of the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com