Exhaust unit and method for low-pressure casting with metal mold

A technology of exhaust device and low pressure casting, which is applied in the field of metal mold low pressure casting exhaust device and exhaust, metal mold precision low pressure casting, can solve the problems of difficult fixing of copper screen, low work efficiency, waste, etc., to achieve the overall effect Good, cost-saving, high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

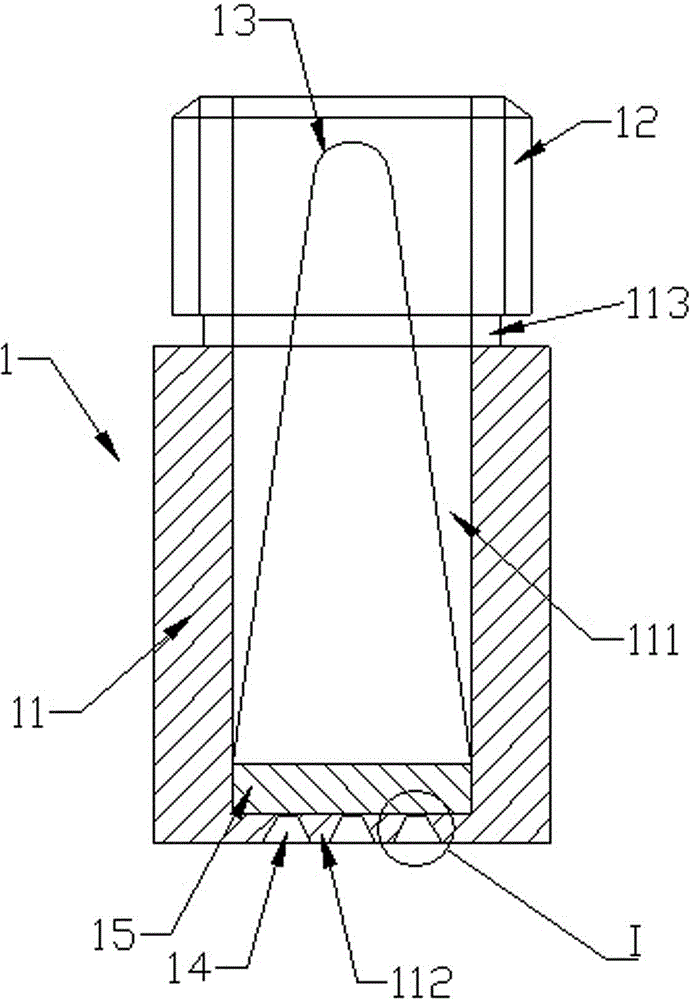

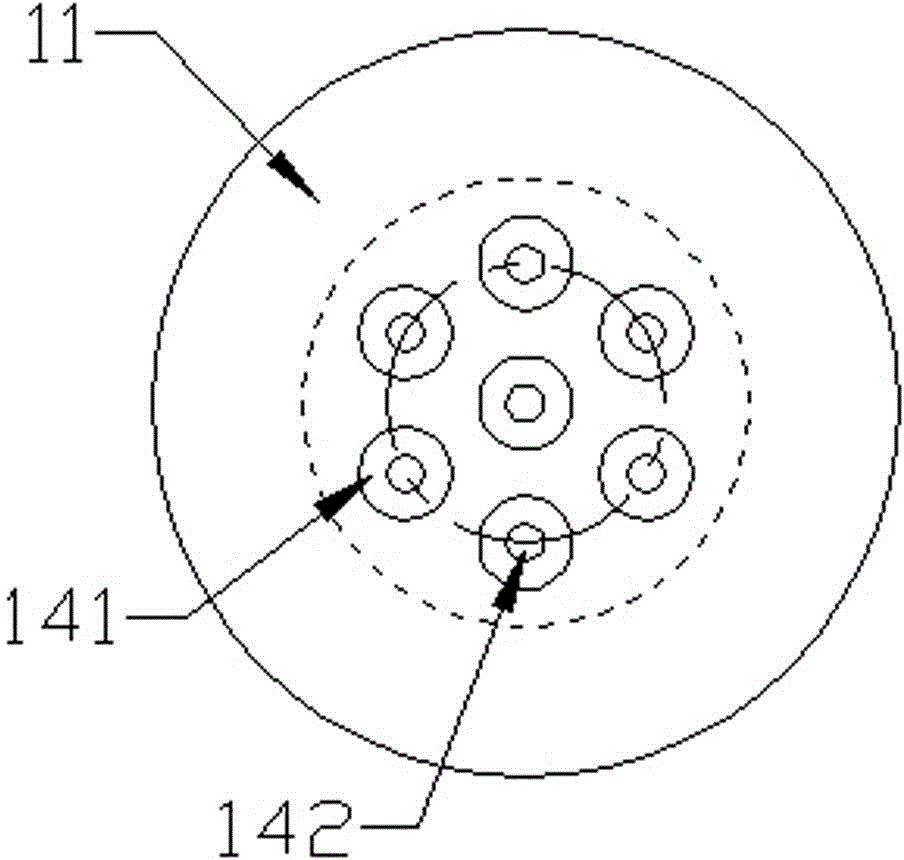

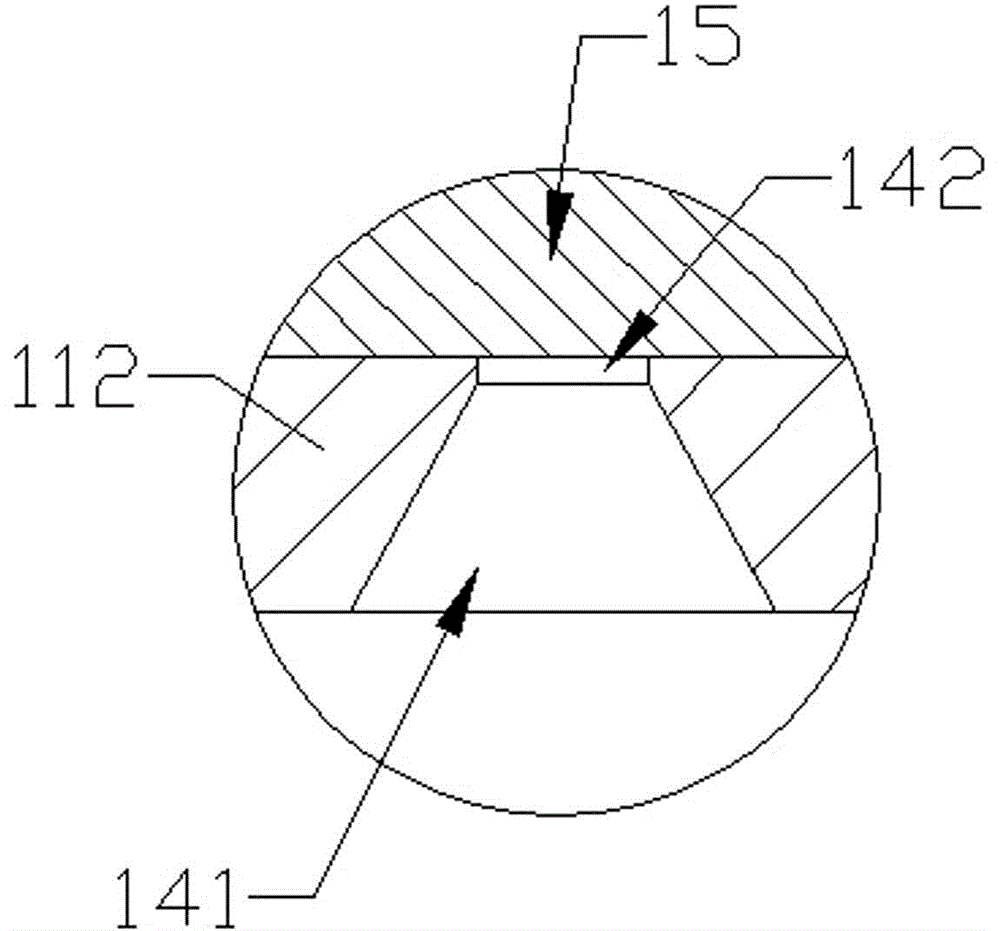

[0036] Example 1, such as figure 1 with figure 2 As shown, a metal type low-pressure casting exhaust device, the exhaust device 1 includes an exhaust device body 11, the exhaust device body 11 is cylindrical, and the center of the exhaust device body 11 is provided with a cavity 111 along the axial direction. The cross section of the cavity 111 is circular, one end of the cavity 111 is open, the other end of the cavity 111 and the end surface on the same side of the exhaust device body 11 are provided with an exhaust device bottom plate 112, and a fixing frame 13 is provided in the cavity 111. A high-temperature-resistant liquid-proof and breathable layer 15 is provided between the fixing frame 13 and the bottom plate 112 of the exhaust device. The high-temperature-resistant liquid-proof and breathable layer 15 is used to realize the overflow of gas generated during the casting process, and at the same time, it can prevent the alloy liquid from seeping out. 13 is used to fix an...

Embodiment 2

[0047] Example 2, such as Figure 8 with Picture 9 As shown, a metal-type low-pressure casting exhaust device includes an exhaust hole 14. The exhaust hole 14 is tapered. The big end of the exhaust hole 14 is located at the bottom to facilitate demolding. The rest of the structure is the same as in embodiment 1. This embodiment I won't repeat it in the example.

[0048] When the exhaust device in this embodiment is applied to the metal mold low-pressure casting process, the exhaust effect is good, the quality of the obtained workpiece is high, and the phenomenon of pores in the workpiece is effectively avoided, but the upper end of the mold release point is prone to thin-shaped sharp surfaces Although it does not affect the quality of the workpiece, it is easy to scratch the operator sometimes.

Embodiment 3

[0049] Example 3, such as Picture 10 As shown, a metal-type low-pressure casting exhaust device includes an exhaust hole 14, which is a straight hole, and the rest of the structure is the same as in Embodiment 1, and will not be repeated in this embodiment.

[0050] When the exhaust device in this embodiment is applied to the low-pressure metal casting process, the exhaust effect is good, the quality of the obtained workpiece is high, and the phenomenon of pores in the workpiece is effectively avoided, but it is difficult to demold. The exhaust hole 14 The solidified aluminum column is easy to block the vent hole and needs to be removed and cleaned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com