Tyre vulcanizer

A technology of tire vulcanization and pushing, which is applied to tires, other household appliances, household appliances, etc., and can solve problems such as imperfections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

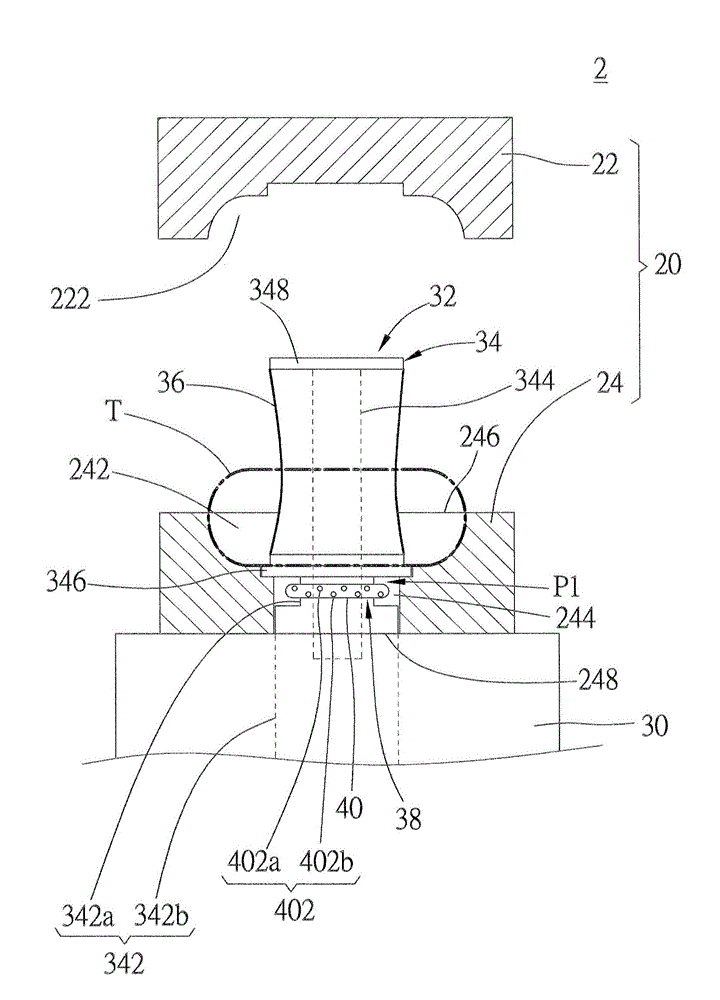

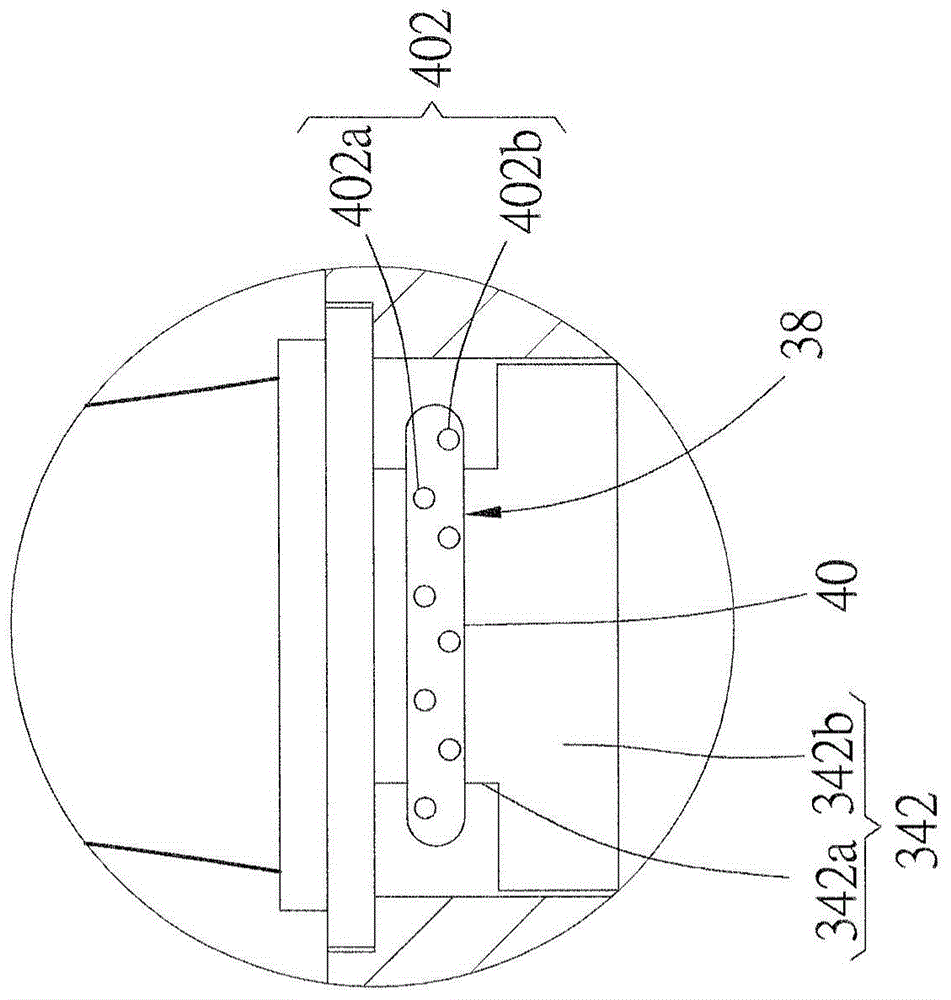

[0031] In order to illustrate the present invention more clearly, preferred embodiments are given together with diagrams in detail as follows.

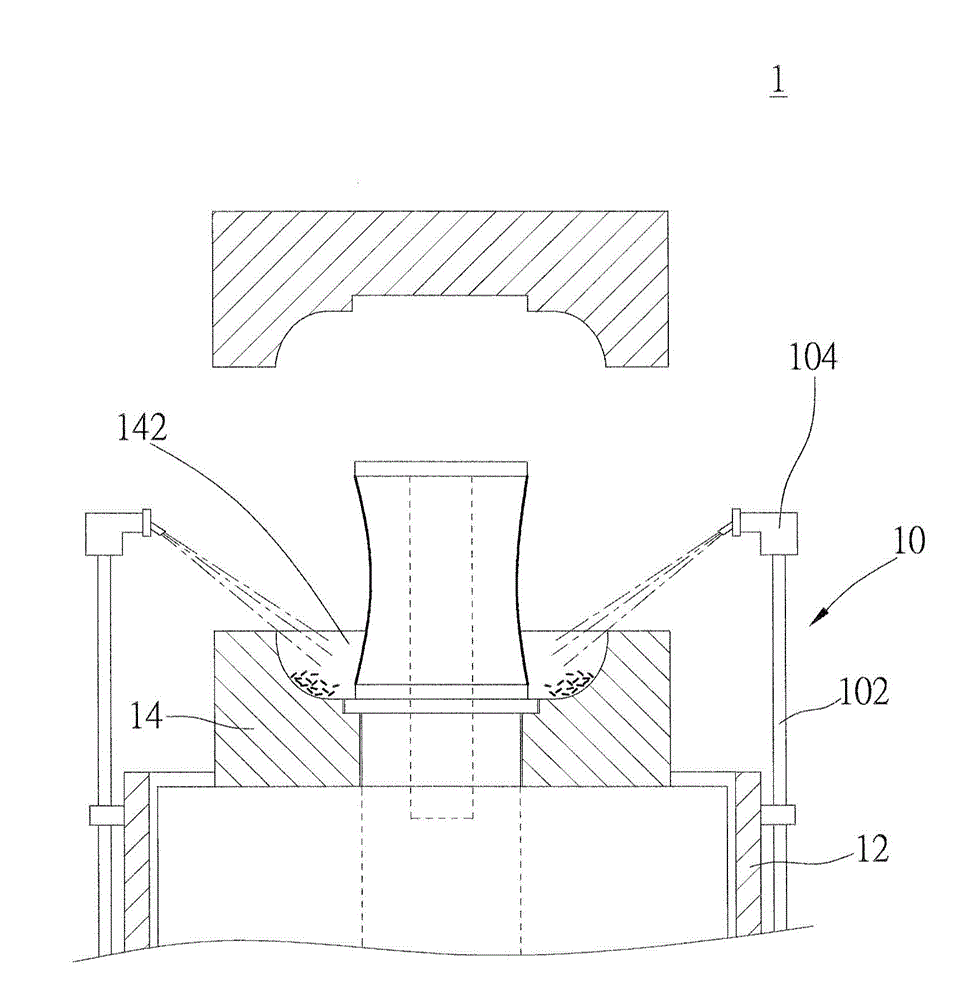

[0032] The tire vulcanizing machine provided by the present invention includes a mould, a pusher, an air bag and an air injection device. Wherein, the mold has an upper mold body and a lower mold body, wherein the lower mold body has a mold cavity and an upper opening and a lower opening communicating with the mold cavity; the upper mold body can be connected to the lower mold body according to a predetermined path Combination or separation; the push piece extends into the lower mold body through the lower opening of the lower mold body, the push piece can reciprocate between a first position and a second position, the push piece When in the first position, it is accommodated in the lower mold body, and when the pusher is in the second position, it protrudes from the upper opening of the lower mold body; the air bag is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com