Ship

A ship and hull technology, applied in the direction of hull, ship construction, ships, etc., to achieve the effects of improving rapidity, improving resistance performance, good flow field and pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

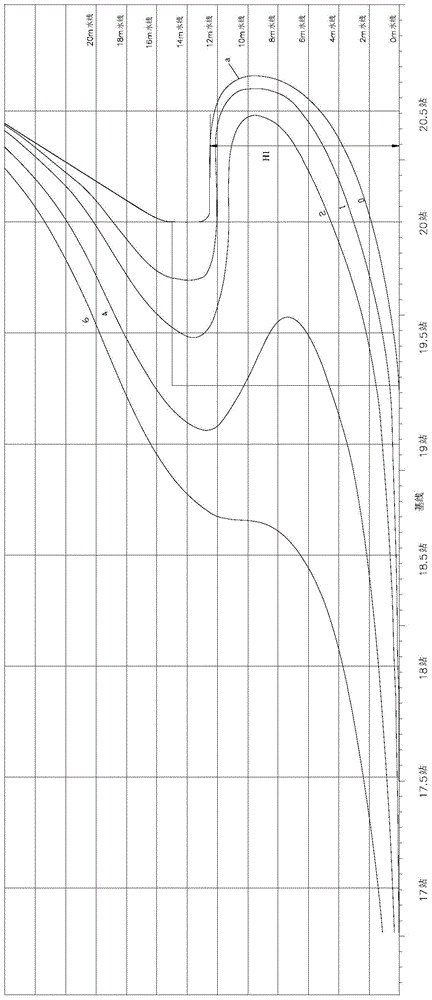

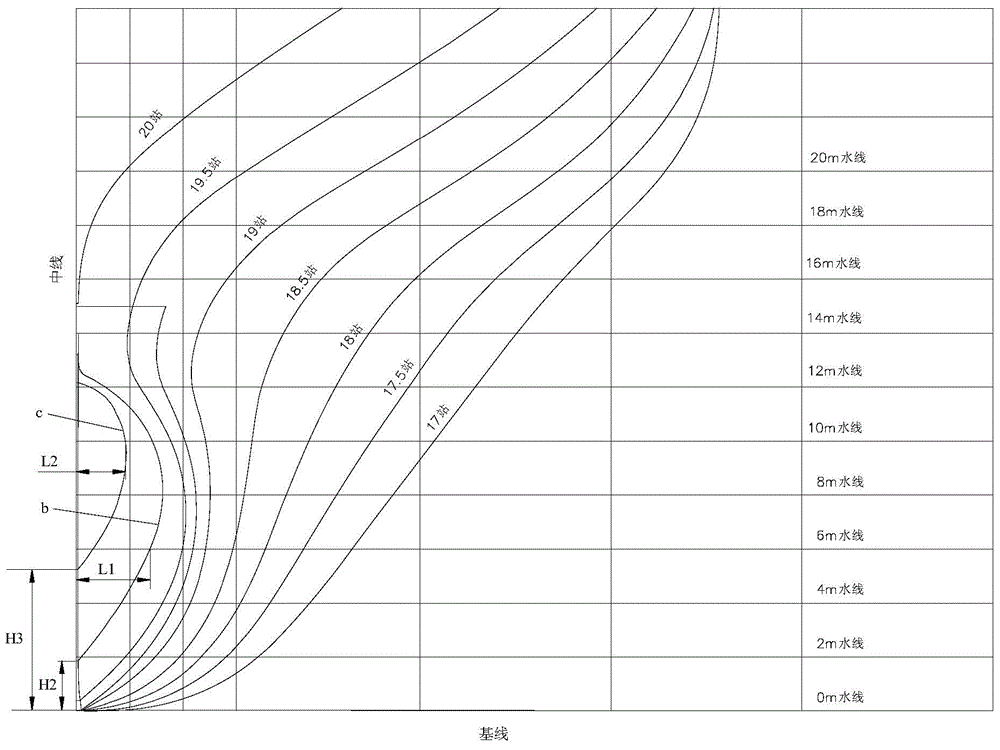

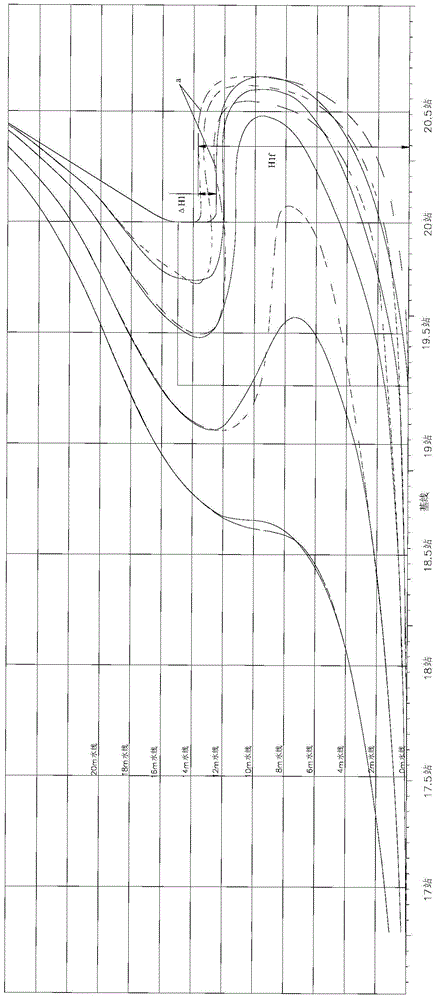

[0014] The present invention is based on the following reference coordinate system when describing dimensions:

[0015] In the X direction, along the length of the ship, it is divided into 20 intervals according to the length of the vertical lines, that is, 20 stations, numbered sequentially from the stern to the bow, the stern perpendicular is 0 station, and the bow perpendicular is 20 stations. If the length between lines is LPP, the length of each station leader is: LPP / 20. In places where the line shape changes rapidly at the bow and stern, add 0.5 or even 0.25 stations. If the range exceeds 20 stations, increase in order, then the distance of 20.5 stations The formula for calculating the length of the stern perpendicular is: LPP+0.5*(LPP / 20);

[0016] Y direction: along the ship's width direction, with the centerline of the ship as 0 point, the starboard side as positive, and the hull is symmetrical left and right;

[0017] Z direction: along the draft direction, take th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com