A Boundary Condition Simulation Device for Acoustic Closed-End Inlet of Liquid Flow System

A boundary condition, simulation device technology, applied in measurement devices, fluid dynamics tests, testing of machine/structural components, etc., can solve problems such as cavitation, large flow resistance, etc., to achieve lightening of the burden, high flow velocity, and uniform flow field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

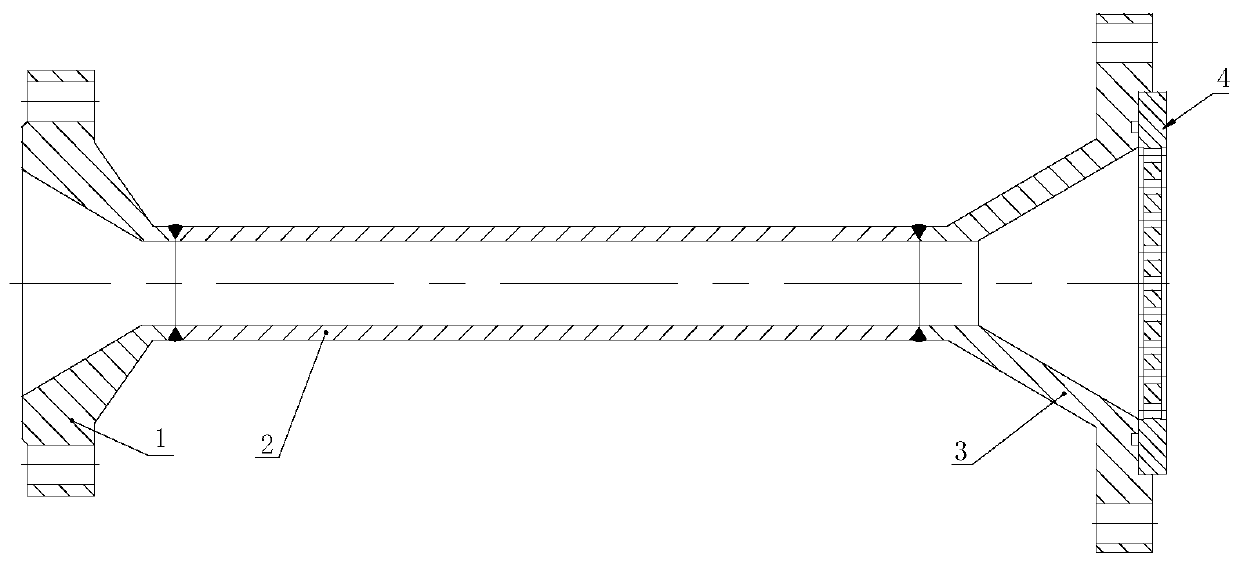

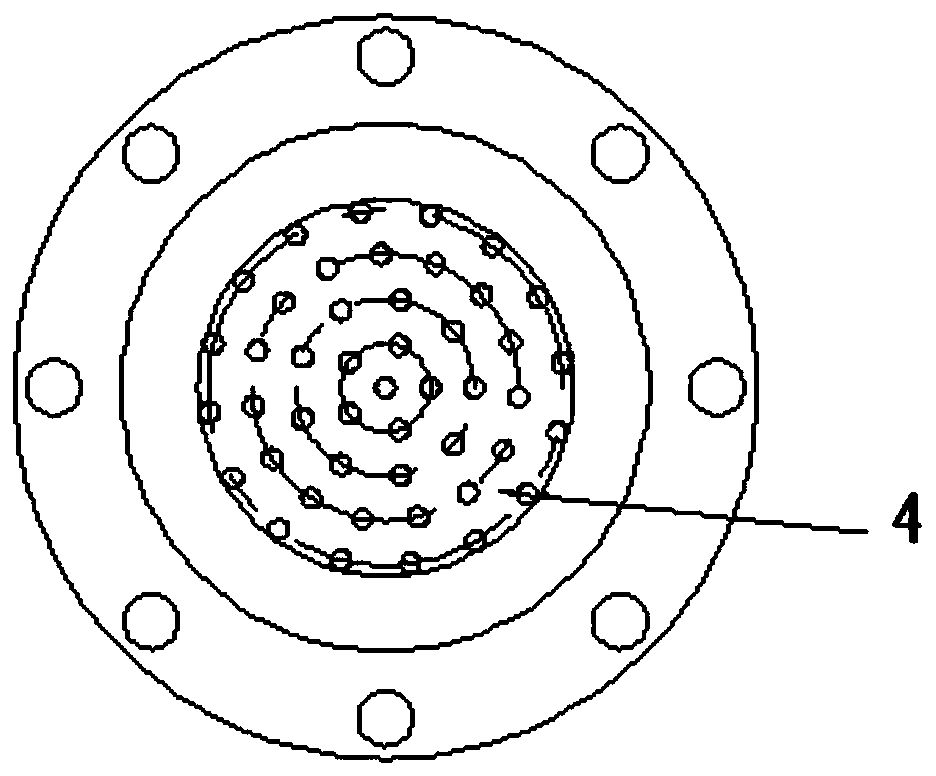

[0020] Such as figure 1 Shown is a schematic cross-sectional view of the center of the simulation device. It can be seen from the figure that a liquid flow system acoustic closed-end inlet boundary condition simulation device is characterized in that it includes a contraction cone 1, a throttle tube 2, an expansion cone 3 and a porous rectification grid 4 ; Wherein, the throttling tube 2 is a hollow cylindrical structure; the contraction cone 1 and the expansion cone 3 are both hollow conical structures; the contraction cone 1 is fixedly installed on the axial end of the throttle tube 2 along the axial direction; and the contraction cone 1 The axial small-diameter end is fixedly connected to the throttle tube 2; the expansion cone 3 is fixedly installed on the other axial end of the throttle tube 2; and the axial small-diameter end of the expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com