Glass turn table

A technology of glass transfer and sheet table, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of slow speed, glass surface scratches, and low work efficiency, and achieve high transfer speed, high work efficiency, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

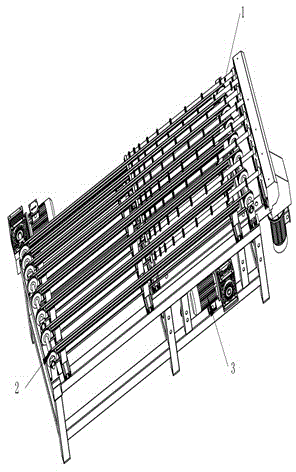

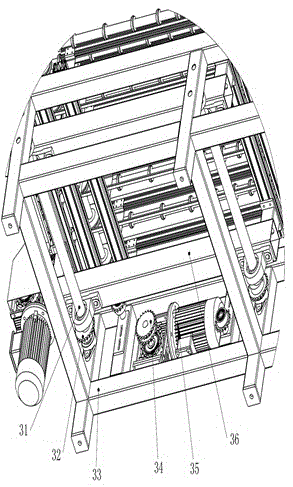

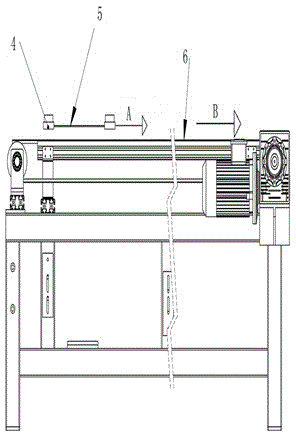

[0010] Refer to the attached figure 1 , 2 , the figure includes: roller transmission part 1, belt transmission part 2, roller lifting part 3, eccentric shaft 31, driven sprocket 32, equipment base 33, driving sprocket 34, lifting motor 35, lifting platform 36.

[0011] It will be described in detail below: the turntable mechanism includes a roller conveying part 1 , a belt conveying part 2 and a roller raising and lowering part 3 . The running direction of the raceway of the roller conveying part 1 and the running direction of the belt of the belt conveying part 2 are at 90 degrees and are respectively consistent with the flow direction of the front and rear glass processing steps.

[0012] The roller conveying part 1 includes a rubber roller, which is composed of a group of rubber rollers arranged at a certain interval. The running direction of the rubber roller (transmission roller table) is consistent with the flow direction of the previous processing process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com