Yeast cell short peptide and yeast cell wall polysaccharide synchronous preparation method

A yeast cell wall and yeast technology, which is applied in the field of synchronous preparation of yeast short peptides and yeast cell wall polysaccharides, can solve the problems of increased salt ion content, mannan degradation, and easy hydrolysis, etc., and achieve great economic benefits and environmental protection significance , increase the utilization rate and added value, the effect of mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Example 1: Preparation of zymosan and short peptide

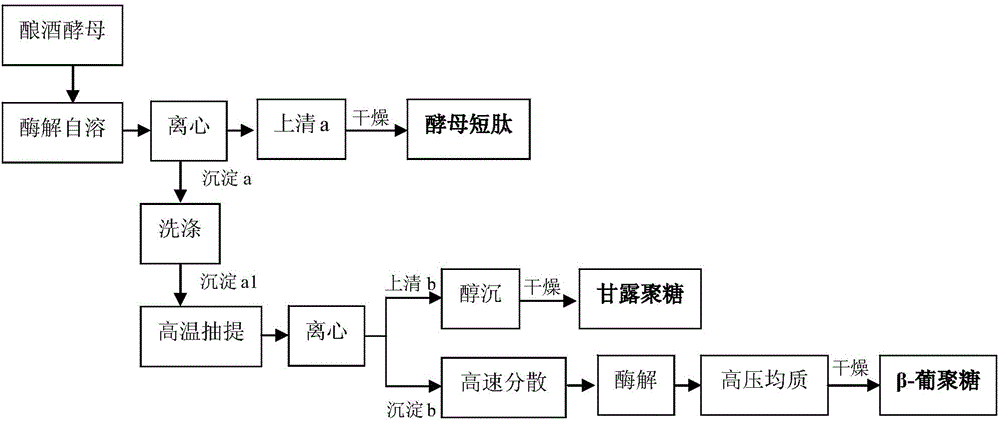

[0035] The simultaneous preparation method of yeast short peptide and yeast cell wall polysaccharide in this embodiment comprises the following steps:

[0036] (1) Saccharomyces cerevisiae was washed with deionized water and then centrifuged to remove impurities, and deionized water was added at a volume ratio of 1:6 to prepare a suspension a, and the neutral protease Neutrase was added to the suspension a at an enzyme amount of 200U / g , under the conditions of pH 7.0 and 55°C, enzymatically hydrolyze and autolyze in a constant temperature deionized water bath shaker for 20 hours, then raise the temperature to 90°C, keep warm for 10 minutes to inactivate the enzyme, and centrifuge to obtain supernatant a and precipitate a respectively;

[0037] (2) using spray drying to dry the supernatant a obtained in step (1) to obtain the yeast short peptide;

[0038] (3) Add deionized water to the precipitate a for centrifugatio...

Embodiment 2

[0043] The simultaneous preparation method of yeast short peptide and yeast cell wall polysaccharide in this embodiment comprises the following steps:

[0044] (1) Saccharomyces cerevisiae was washed with deionized water, centrifuged to remove impurities, and deionized water was added at a volume ratio of 1:4 to prepare a suspension a, and neutral protease Neutrase was added according to the amount of enzyme added at 200U / g, and placed at pH 7.0 and 55 Enzymolysis and autolysis at ℃ for 24 hours, warming up to 90℃, inactivating the enzyme by incubating for 10 minutes, and centrifuging to obtain supernatant a and precipitate a respectively;

[0045] (2) using spray drying to dry the supernatant a obtained in step (1) to obtain the yeast short peptide;

[0046] (3) Add deionized water to the precipitate a for centrifugation to obtain precipitate a1, and then add deionized water to the precipitate a1 at a mass ratio of 1:4 (the mass ratio of precipitate a1 to deionized water is 1...

Embodiment 3

[0051] The only difference between this example and Example 1 is that the volume ratio of Saccharomyces cerevisiae and deionized water in step (1) is 1:5, the dosage of neutral protease Flavorzyme is 300U / g, and when enzymatic hydrolysis is used for autolysis, The temperature is 40°C, the time is 30h, and the pH value is 8.0.

[0052] The yeast short peptide prepared in this example is a milky white powder with a short peptide content of 90.46%; the β-glucan is a milky white powder with a β-glucan content of 94.42%; the yeast mannan is a white powder with a mannan content of was 93.84%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap