Plug-in type molten iron slag blowing spray gun

A plug-in, spray gun technology, applied in the field of plug-in molten iron slag blowing spray guns, can solve problems such as unsystematic research on the mechanism of top gun blowing and slag removal, affecting the research on the structure design of the spray gun, and crisis safe operation of molten iron tanks, etc., to achieve improvement The effect of blowing slag, improving the high temperature damage resistance, and strengthening the effect of inhibition and guiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

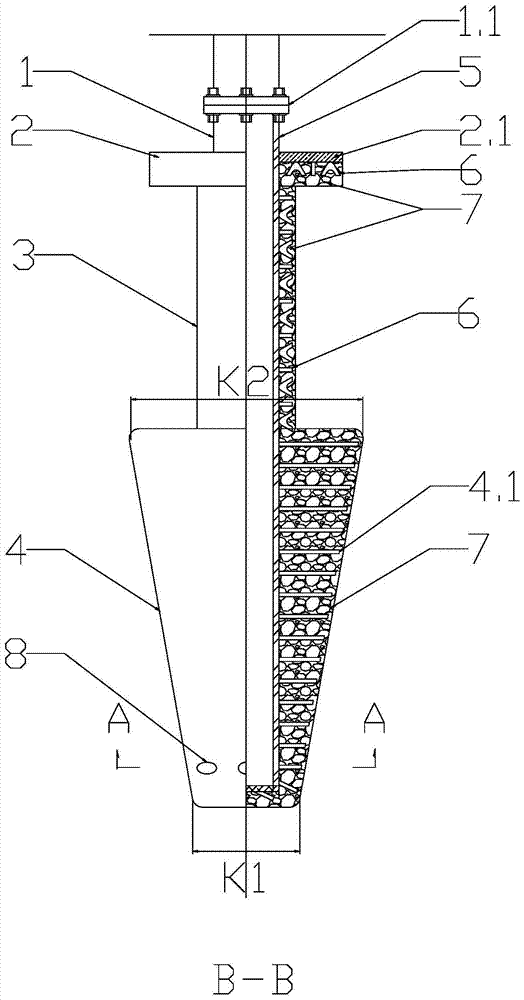

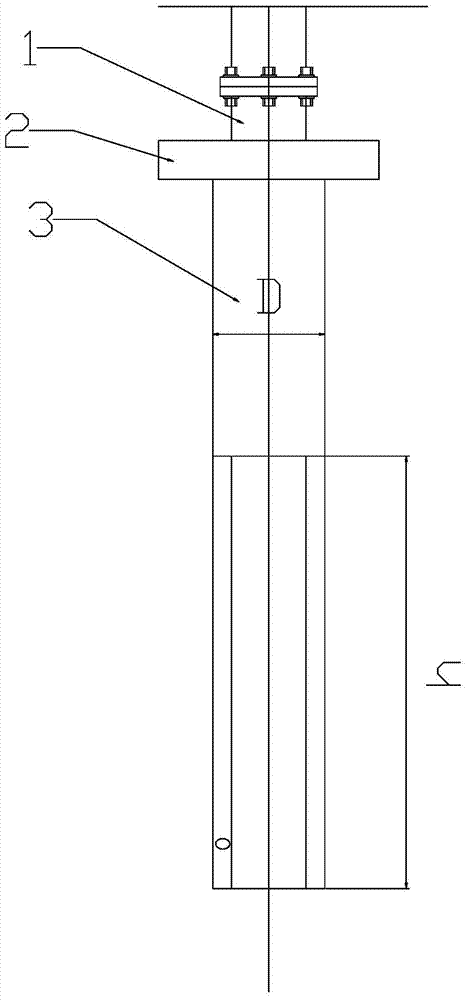

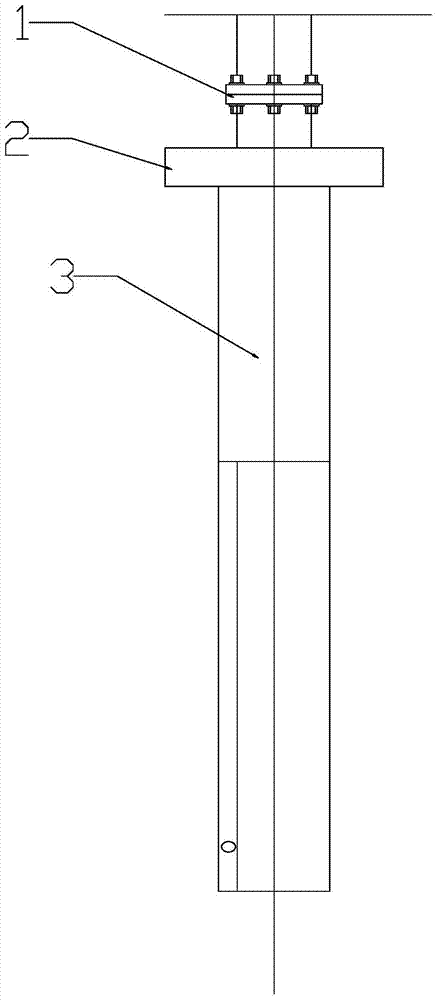

[0040] Such as figure 1 , 2 Shown in and 5: a plug-in molten iron slag blowing spray gun, including a connecting section 1 and a spray gun main body 3 connected in sequence, and a splash-proof disk 2 perpendicular to the spray gun main body 3 is connected between the connecting section 1 and the spray gun main body 3 , with the centerline plane of the spray gun body 3 as the symmetry plane, the damper vane 4 is symmetrically arranged, the connecting section 1 is composed of the connecting piece 1.1 and the core tube 5, the splash-proof disk 2 includes the core tube 5, and the outer wall of the core tube 5 A metal disc 2.1 perpendicular to the core tube 5 is provided, the lower surface of the metal disc 2.1 is evenly welded with a V-shaped anchor 6, and the lower surface of the metal disc 2.1 and the V-shaped anchor 6 are poured and wrapped with a refractory castable lining 7 , the spray gun main body 3 includes a core tube 5, and the outer wall of the core tube 5 is provided ...

Embodiment 2

[0045] Such as figure 1 , 3 , Shown in 6: a kind of plug-in type hot metal slag removal blowing spray gun, compared with embodiment 1, the difference of spray gun structure is:

[0046]The thickness d of the damper vane 4 shrinks inwards and thins gradually along the width direction on the front surface, and the rear surface is flat. Others are the same as in the embodiment, and the usage method is also the same as in the first embodiment.

Embodiment 3

[0048] Such as figure 1 , 4 , shown in 5: compared with embodiment 1, a kind of hot metal slag removal and air blowing spray gun differs in the structure of the spray gun in that: the spray gun main body 3 is an arc-shaped curved structure toward the tank wall behind the molten iron from top to bottom, and the flow control flap 4 Together with the spray gun main body 3, it also has an arc-shaped bending structure towards the tank wall behind the molten iron. Other is identical with embodiment, and using method is also identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com