Head structure of embroidery machine of towel

An embroidery machine and machine head technology, which is applied to the mechanism of embroidery machines, embroidery machines, textiles and paper making, etc., can solve the problems of high technical requirements of production personnel, complex machine structure, high price and cost, and avoid physical health and simplify machinery. structure, the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

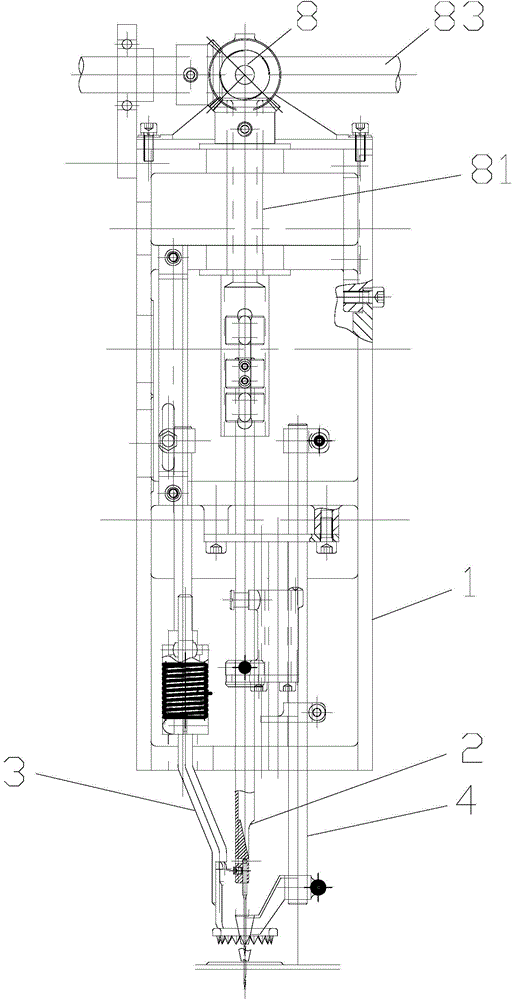

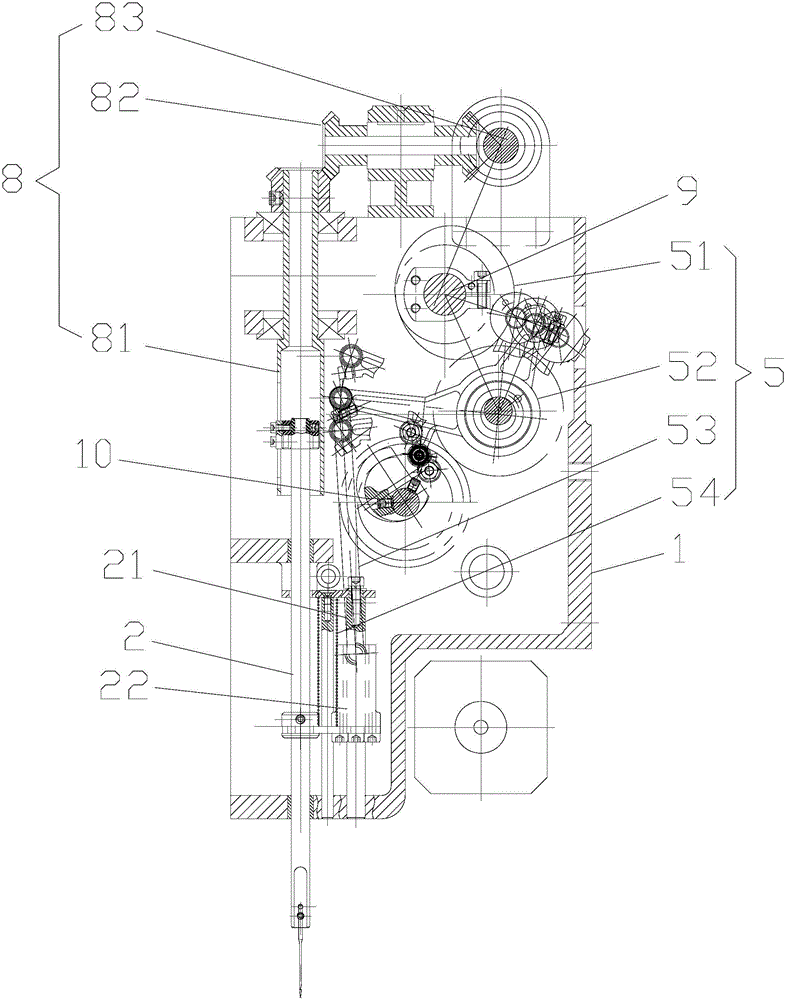

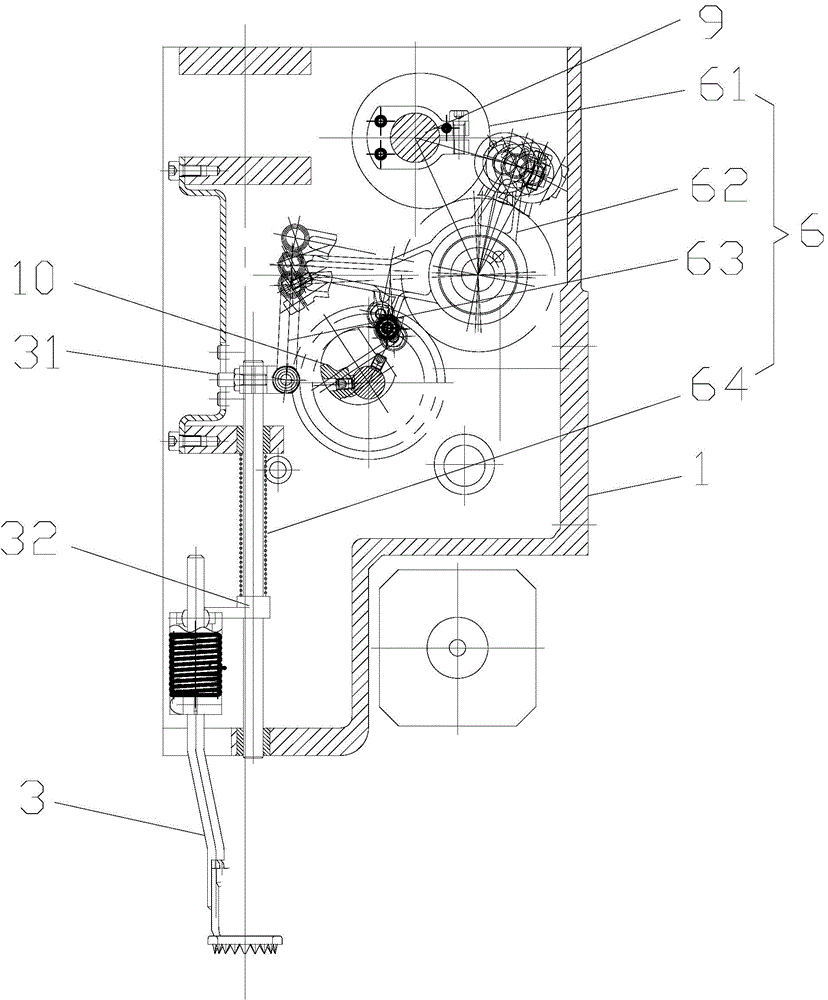

[0019] refer to Figure 1 to Figure 4 , the head structure of a towel embroidery machine provided in this embodiment includes a casing 1, a needle bar 2 installed in the casing 1, and a small presser bar 4. The needle bar 2 and the small presser bar 4 They are spaced apart from each other, the needle bar 2 and the small presser bar 4 can move up and down and are respectively connected with the driving mechanisms I, III 5, and 7, and the three driving mechanisms respectively drive the needle bar 2 and the small presser bar 4 to move up and down . The needle bar 2 can also rotate and is connected with a rotary drive mechanism 8, the drive mechanism I5 includes a cam I51 connected to the power shaft 9, a rocker I52 connected to the cam I51, a rocker I53 connected to the rocker I52 and a reset The spring I54, the rocker I53 is connected with the needle bar 2, and the middle part of the rocker I52 is hinged in the casing 1. Further, the contact surface between the cam I51 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com