Double-chamber prefabricated pump station

A pumping station and water pump technology, which is applied in the field of double-chamber prefabricated pumping stations, can solve the problems of inconvenient maintenance, high processing cost and high production cost, and achieve the effects of low production cost, high bearing capacity and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

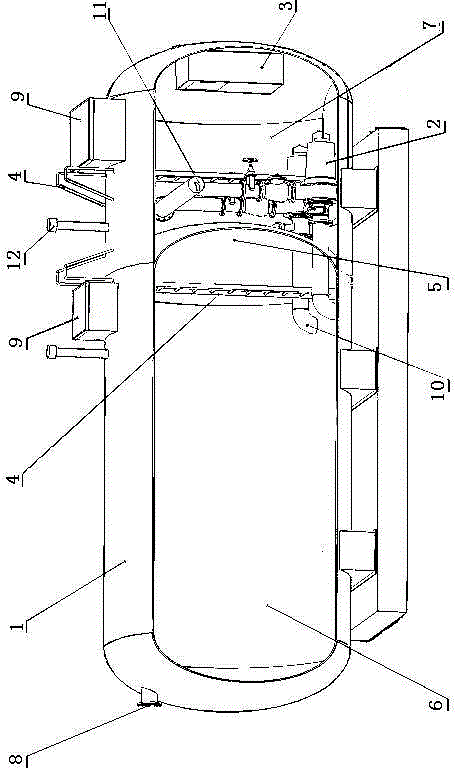

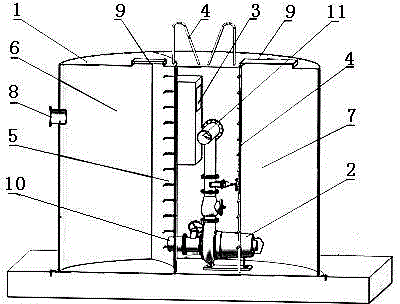

[0013] As shown in the accompanying drawings, a double-chamber prefabricated pumping station is provided with a tank body 1, and a water pump 2, an electric control cabinet 3, a liquid level sensor and a ladder 4 are arranged in the tank body 1, and it is characterized in that the tank body 1 is equipped with A partition 5, the partition is arc-shaped, the periphery of the partition 5 is sealed and connected with the inner wall of the tank body 1, the partition 5 divides the tank body 1 into a water storage chamber 6 and an equipment room 7, the water storage The top surfaces of the chamber 6 and the equipment chamber 7 are respectively provided with an inspection port 9, and an air outlet 12 may also be provided. The arc-shaped convex surface of the partition plate 5 faces the equipment chamber 7, so as to increase the water storage capacity of the water storage chamber 6, and at the same time , also increased the bearing capacity of the water storage chamber 6 walls, the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com