Precast outer wallboard connecting box and connecting joint

A technology for connecting nodes and external wall panels, which is applied in the direction of construction and building construction, and can solve problems such as poor installation accuracy, construction errors in pouring concrete, and inability to adjust, so as to facilitate the installation of waterproofing, improve construction efficiency, and speed up construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

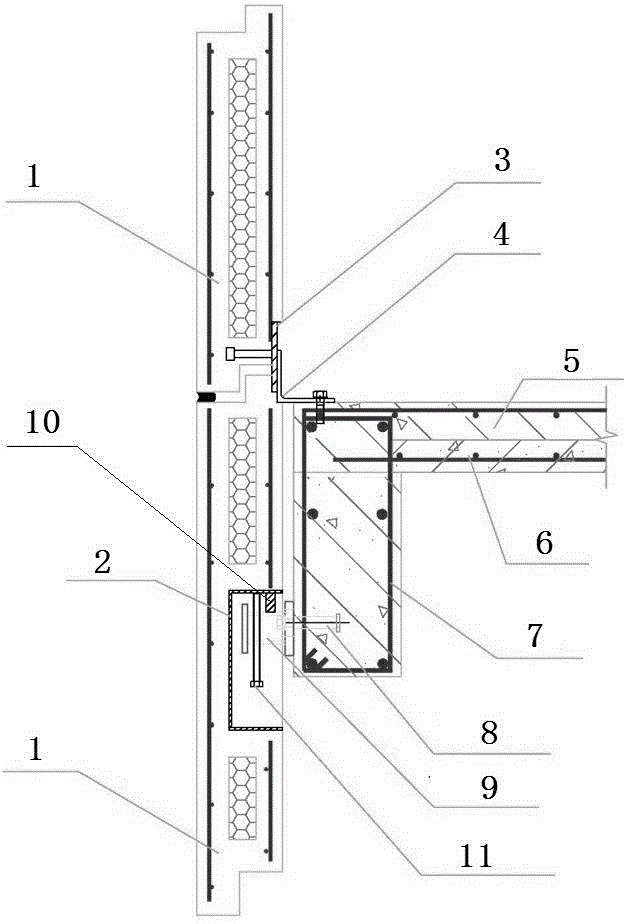

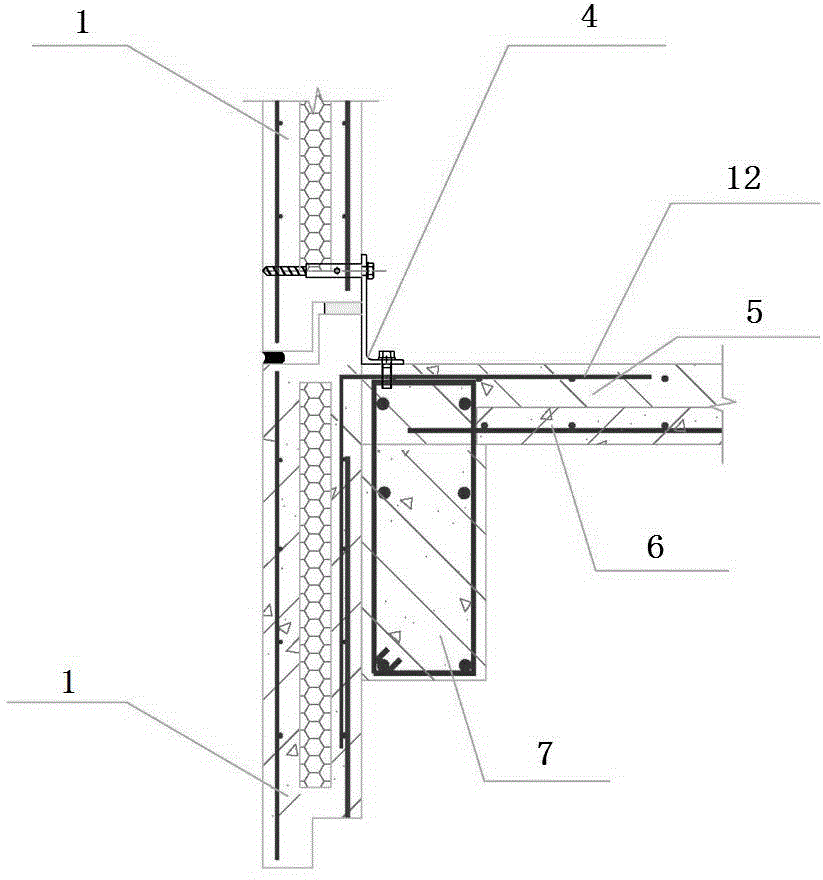

[0017] see figure 1 , the prefabricated exterior wall panel connection box of the present invention is a pre-embedded iron box with an open outer surface. Adjusting bolts, the pre-embedded iron box is also horizontally inserted into the dry-hanging support, the outer wall panel adjusting bolt passes through the bolt hole of the dry-hanging support, and the top end of the outer wall panel adjusting bolt is pushed against the inner top plate of the pre-embedded iron box. A sleeve connection hole is arranged on the outer plate of the dry-hanging support.

[0018] The opening of the outer side of the above-mentioned pre-embedded iron box is in the same vertical plane as the inner side of the prefabricated outer wall panel.

[0019] Nuts are sheathed on the adjusting bolts of the exterior wall panels, and the nuts are connected and fixed with the dry-hanging supports.

[0020] A connection node adopting the connection box of the prefabricated exterior wall panel in the above tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com