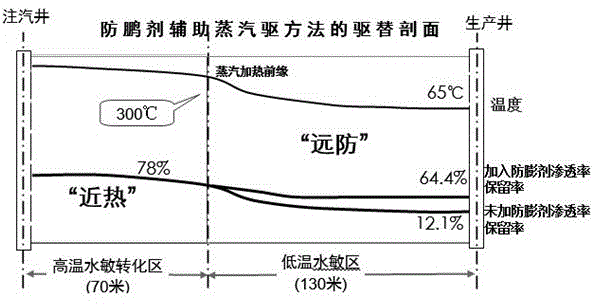

A method of using an anti-swelling agent to help a steam flooding in improving the recovery ratio of water-sensitive heavy oil reservoirs

A technology for assisting steam and heavy oil reservoirs. It is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc. It can solve problems such as oil retention in the ground, and achieve the effect of improving oil recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Example: WZ36-5-5 well group steam flooding test, the oil reservoir where the well group is located has a buried depth of 900-1600m, and the effective thickness of the oil layer is not less than 6m. 200×10 -3 μm 2 of oil reservoirs.

[0018] (1) Calculate the injection volume of anti-swelling agent: the pore volume of the WZ36-5-5 well group is 52.5 Ha m, and the steam flooding swept volume is about 0.5 times the pore volume of the well group, and the anti-swelling agent is calculated at 0.5 times the pore volume The injection volume should be 2625m 3 .

[0019] (2) Dilute the high-concentration mother liquor with prepared water to a concentration of 1% and a volume of 2625m 3 anti-swelling agent solution.

[0020] (3) Mix the anti-swelling agent solution and steam at a ratio of 1:5 and inject it into the oil layer through the steam injection well for 110 days; The injection speed is 5t / h.

[0021] (4) Inject steam separately, and the steam injection rate is 6t / h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap