A Portable Calibration Platform for Steam Turbine Differential Expansion and Shaft Displacement Instrument

A technology of axial displacement and displacement table, which is applied in the field of portable calibration platform for steam turbine differential expansion and axial displacement instruments, can solve the problems of affecting the accuracy of instrument calibration, cumbersome operation, large return error, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

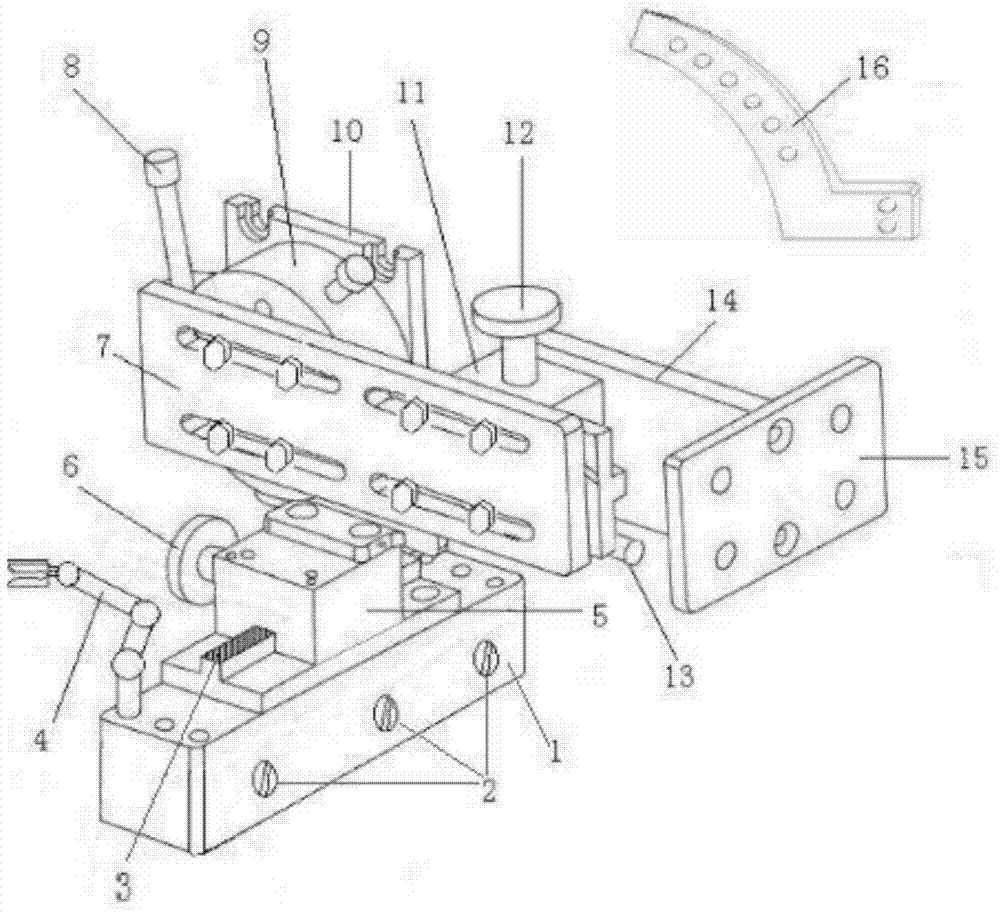

Embodiment 1

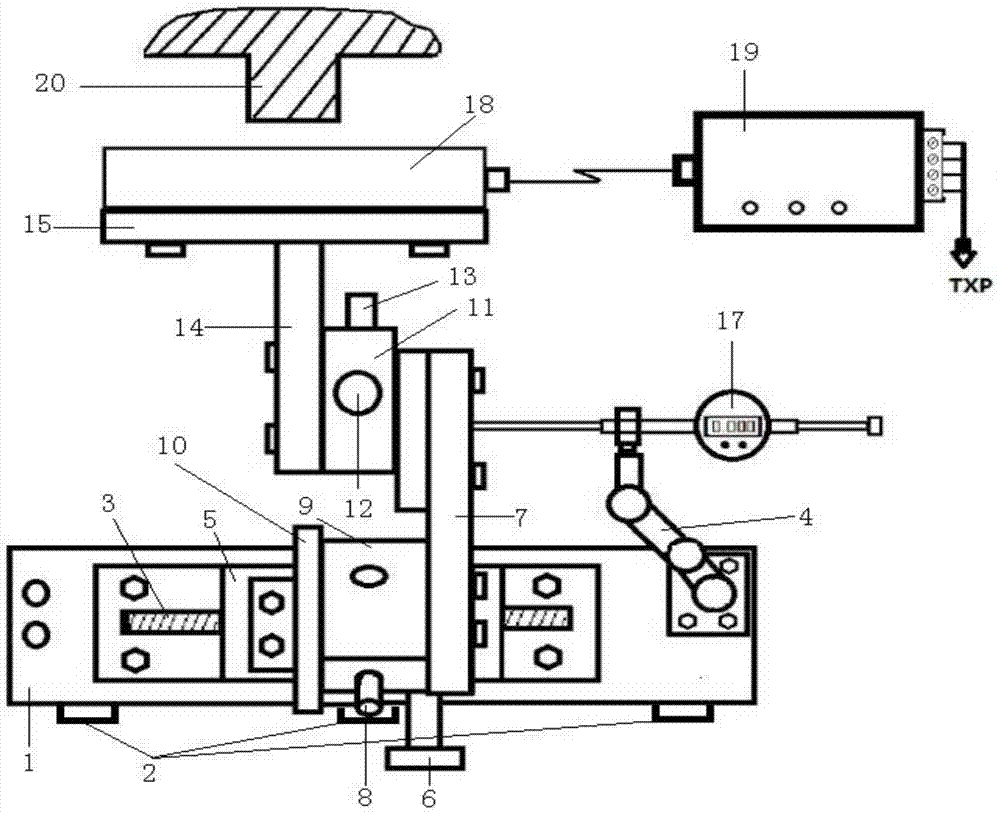

[0030] Such as figure 2 As shown, when calibrating the differential expansion instrument of the steam turbine:

[0031] 1.1. Install the differential expansion instrument 18 to be verified with the fixed module 15 of the differential expansion instrument;

[0032] 1.2. Place the portable calibration table on the cylinder block of the steam turbine, adjust the gap between the instrument to be calibrated and the rotor cam 20 through the rotary table 9 and the displacement table 11, close the locking switch 2, and fix the calibration table ;

[0033] 1.3. Fix the dial gauge 17 on the calibration platform through the dial gauge fixing arm 4, and adjust the dial gauge to keep it level with the translation platform 5.

[0034] 1.4. Rotate the translation knob 6 to simulate the relative expansion of the rotor and the cylinder and the axial displacement of the rotor, and read the relative displacement through the dial gauge;

[0035] 1.5. According to the recorded data, it is judg...

Embodiment 2

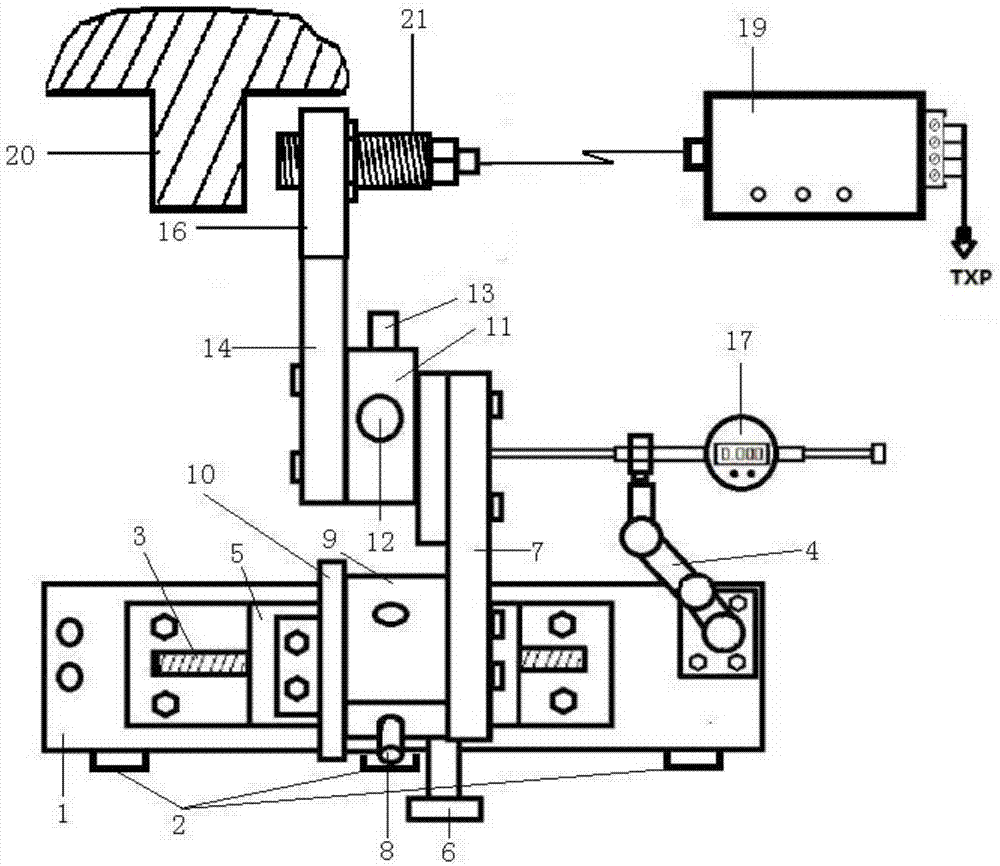

[0037] Such as image 3 As shown, to calibrate the shaft displacement instrument of the steam turbine:

[0038] 2.1. The shaft displacement meter 21 to be verified is installed through the shaft displacement meter fixing module 16, and six shaft displacement meters can be installed at the same time;

[0039] 2.2. Place the portable calibration table on the cylinder block of the steam turbine, adjust the gap between the instrument to be calibrated and the rotor cam through the rotary table 9 and the displacement table 11, close the locking switch 2, and fix the calibration table;

[0040] 2.3. Fix the dial gauge 17 on the calibration platform through the dial gauge fixing arm 4, and adjust the dial gauge to keep it level with the translation platform 5.

[0041] 2.4. Rotate the translation knob 6 to simulate the relative expansion of the rotor and the cylinder and the axial displacement of the rotor, and read the relative displacement through the dial gauge.

[0042] 2.5. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com