Force actuator based on pulling and pressing spring sets

A technology of tension and compression springs and force actuators, which is applied in the direction of instruments, optical components, optics, etc., can solve the problems of low force output accuracy of mechanical force actuators, achieve good linearity, overcome zero-point lag, and eliminate air-back gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

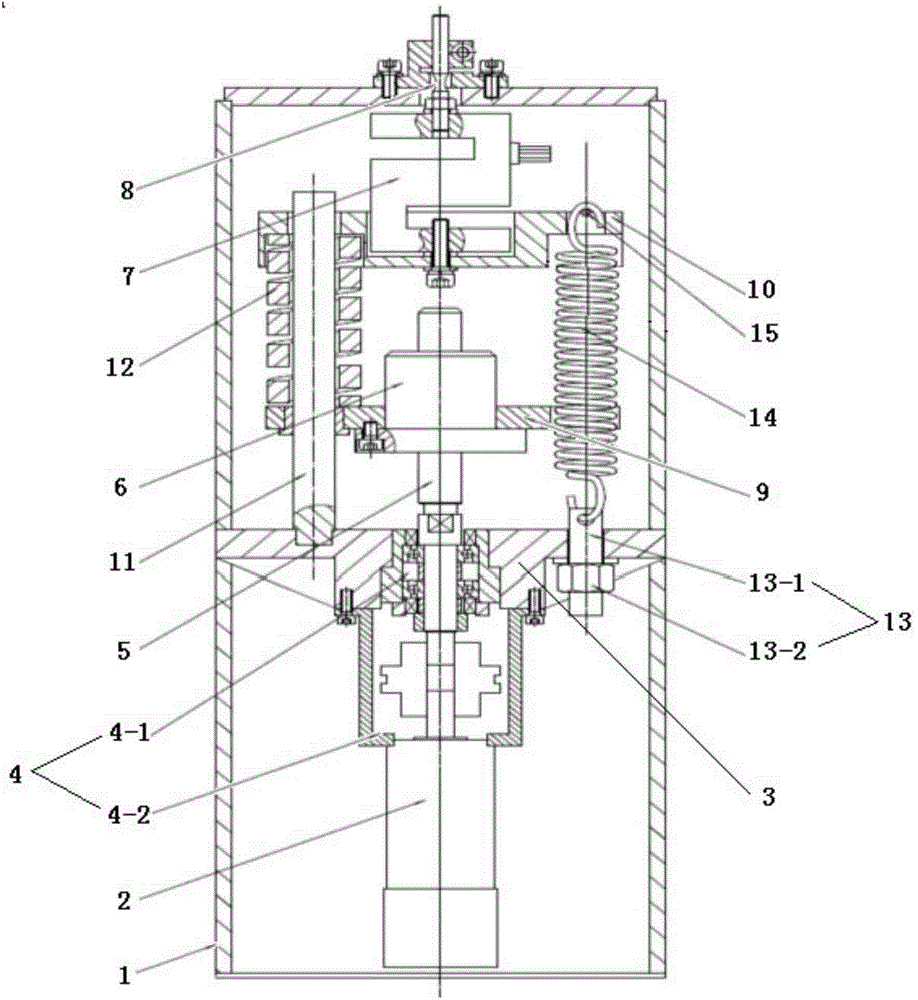

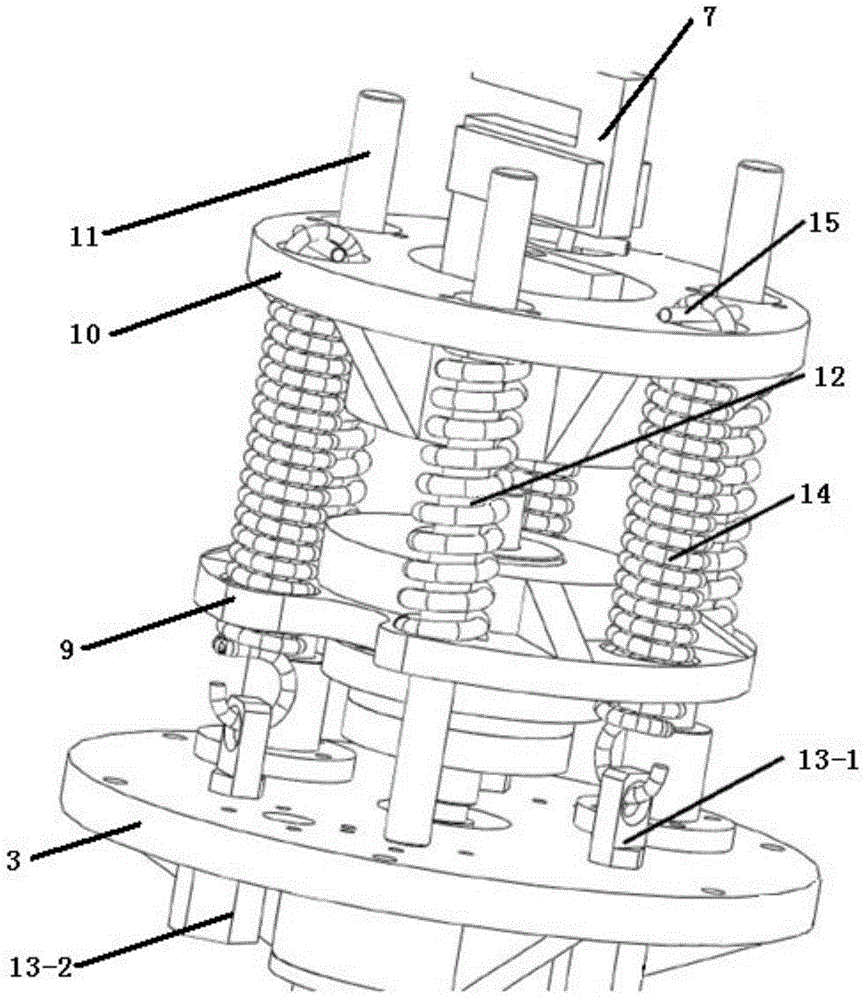

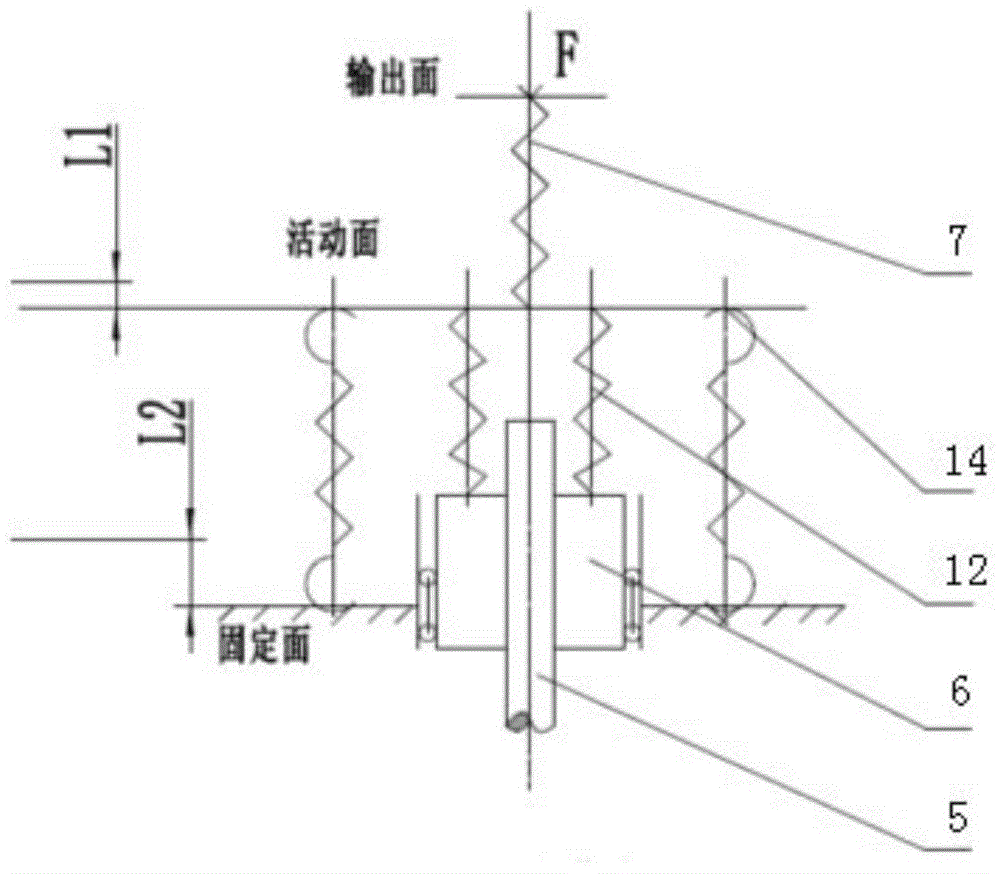

[0026] Such as Figure 1-2 As shown, the force actuator based on the tension and compression spring group of the present invention includes: a housing 1, a motor 2, a fixed seat 3, a fixing mechanism 4, a ball screw 5, a nut 6, a force measuring element 7, an output shaft 8, a A spring cage 9, a second spring cage 10, a guide shaft group, a compression spring group, an adjustment mechanism group and an extension spring group.

[0027] Wherein, the fixing seat 3 is fixed on the inner wall of the housing 1 . The fixing mechanism 4 is fixed on the fixing seat 3 , and one end of the fixing mechanism 4 is fixedly connected with the ball screw 5 , and the other end is fixedly connected with the motor 2 . Generally, the motor 2 is a stepping motor, the fixed seat 3 is a bearing seat, and the fixed mechanism 4 is composed of a bearing 4-1 and a coupling 4-2. The be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com