Method for predicting test-flight fault load

A load and fault technology, applied in calculations, special data processing applications, instruments, etc., can solve problems such as time-consuming and low calculation accuracy, and achieve the effects of reducing uncertainty, improving design efficiency, and shortening troubleshooting and design time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

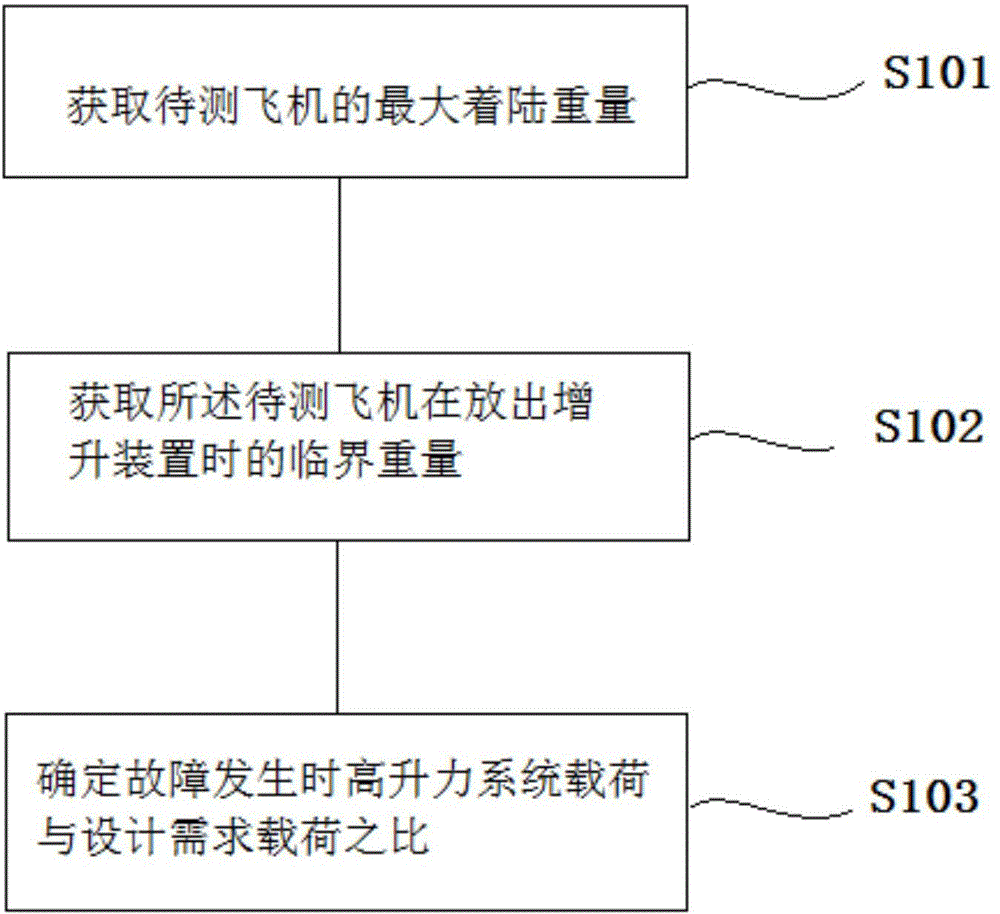

[0021] Such as figure 1 As shown, a kind of flight test failure load prediction method provided by the present invention comprises:

[0022] Step S101, obtaining the maximum landing weight of the aircraft to be tested.

[0023] Step S102, obtaining the critical weight of the aircraft under test when the high-lift device is released.

[0024] Step S103, according to the following formula (1), determine the ratio η of the high-lift system load to the design demand load when the fault occurs:

[0025] η = W 1 W 0 × 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com