Water-blocking expansion glue filling system and filling method for cable multi-strand conductor or cable core

A filling system and water blocking technology, applied in the direction of insulating conductors/cables, etc., can solve the problems of inability to fill multi-strand conductors or cable cores of cables, failure of the whole system to work normally, line failures, etc., to ensure the water blocking effect. , good consistency, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

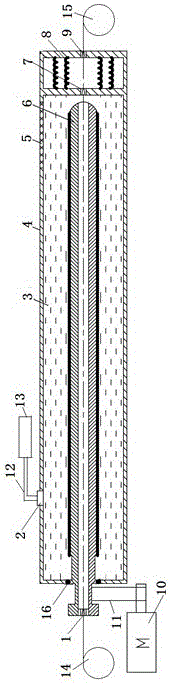

[0012] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0013] Such as figure 1 , 2 , 3, a water-blocking expansion glue filling system for cable multi-strand conductors or cable cores, including water-blocking expansion glue 3, screw rod 6, heating device 8, motor 10, gear 11, glue filling connecting pipe 12, automatic filling Glue machine 13, pay-off spool 14, take-up spool 15, rolling bearing 16 also include wire passing die 1, glue filling hole 2, machine barrel 4, transparent observation window 5, rubber scraping die 7, sizing die 9.

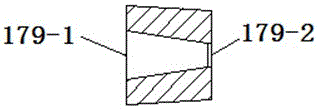

[0014] The wire passing die 1, the rubber scraping die 7 and the sizing die 9 are all of the same structure, and are circular bodies, one end face of the circular body is the wire inlet hole 179-1, and the other end face is the wire outlet hole 179-2, and the wire inlet hole There is a funnel-shaped hole between the inlet of 179-1 and the inlet of outlet hole 179-2.

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com