A large garment production line

A production line and clothing technology, applied in the direction of sewing tools and other directions, can solve the problems of large batches, high labor costs, and a single type of clothing, etc., and achieve the effect of flexible production, high degree of humanization, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

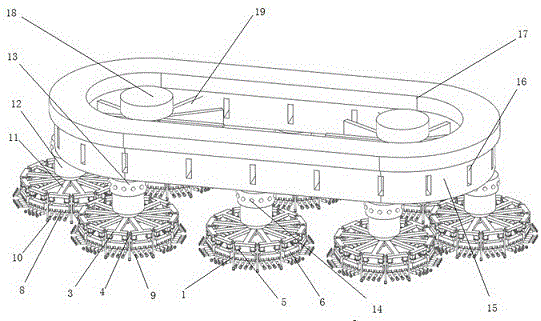

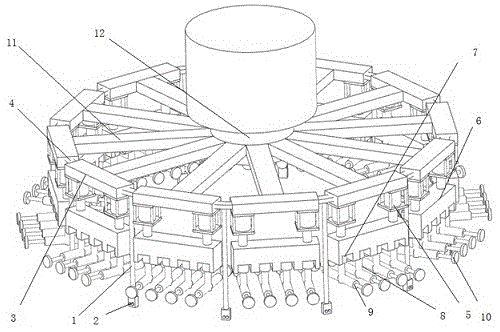

[0023] The invention provides a large-scale garment production line, which is composed of a plurality of small assembly line work units, and each small assembly line work unit can independently carry out small batch flow production of corresponding styles, thereby greatly improving production efficiency and effectively Reasonable use of factory space is especially suitable for small batch production of fast fashion clothing business models.

[0024] As an embodiment of the present invention, the present invention provides a large-scale garment assembly line, which includes a working unit, a working unit fixing frame 13, a transmission belt 15, a main fixing frame 17, an active motor 18 and a toggle plate 19, and the upper end of the transmission belt 15 is It is clamped in the groove below the main fixing frame 17. There is a group of strip grooves 16 in the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com