Trailer box with brake anti-rotation

An anti-rotation and action technology, applied in the field of luggage, can solve the problem of unbalanced force, such as the car spinning, and achieve the effect of balanced braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

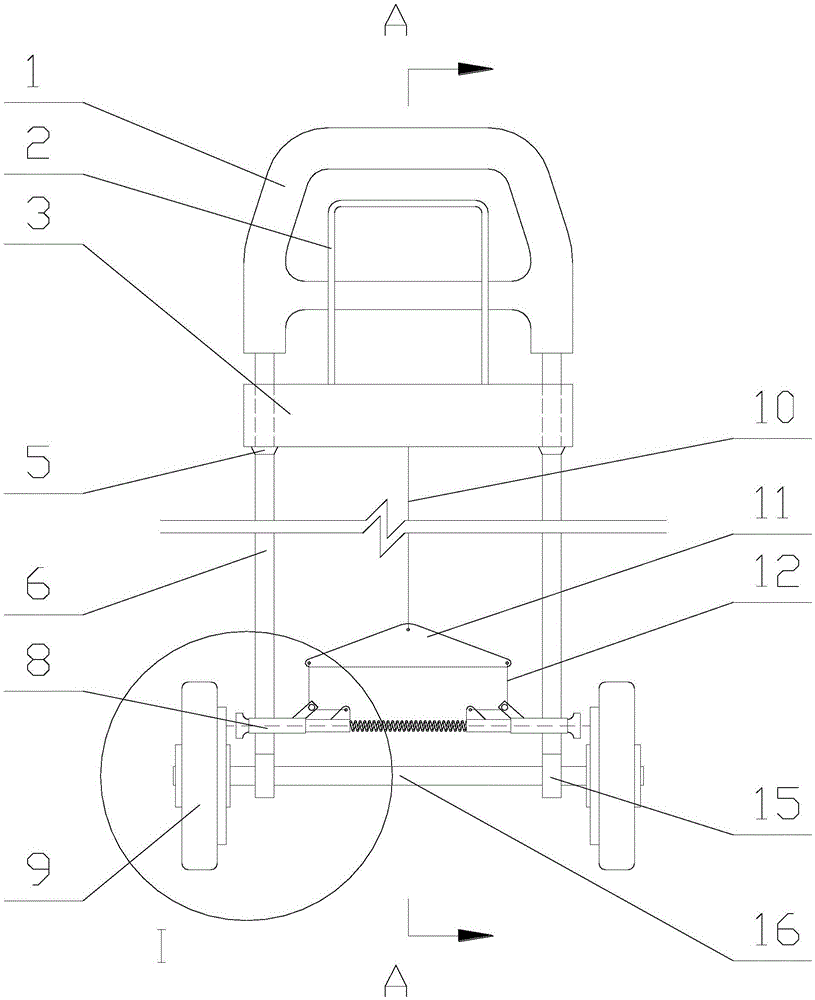

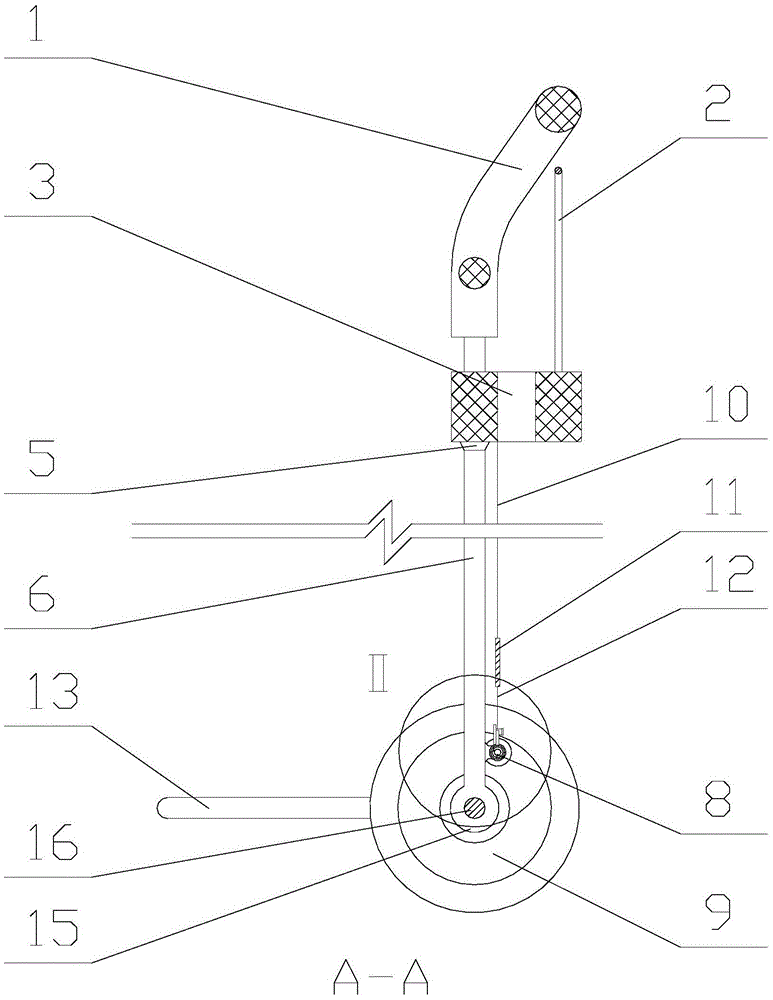

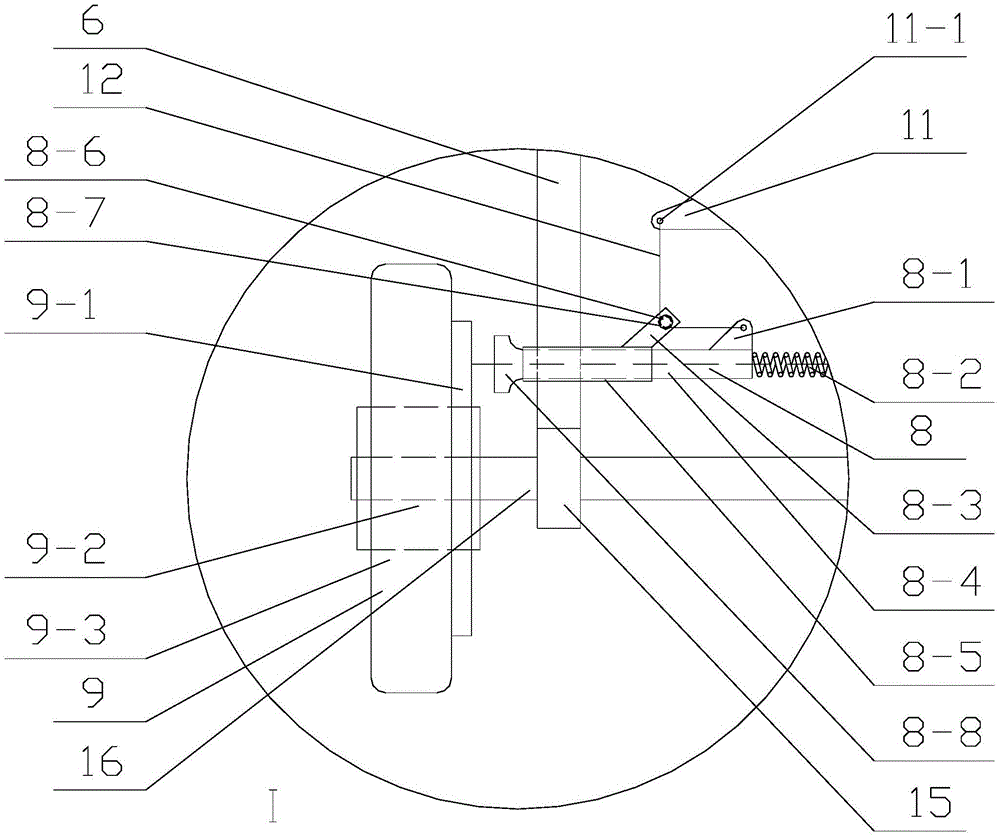

[0045] 1. The drag box with brake anti-rotation function, including: pull rod handle 1, brake handle 2, sliding device 3, sliding device stop 5, pull rod 6, braking device 8, wheel assembly 9, central brake cable 10, Brake force equalizer bar 11, brake cable hole 11-1, side wing brake cable 12, support frame 13, pull rod bushing 15, wheel axle rod 16;

[0046] It is characterized by:

[0047] The braking device 8 is two groups of left and right symmetry, and the braking device 8 includes: a brake cable connection seat 8-1, a return spring 8-2, a guide shaft support 8-3, a brake shoe pillar 8-4, and a pillar sleeve 8-5, brake cable guide shaft 8-6, brake cable stopper 8-7, brake shoe 8-8;

[0048] The wheel assembly 9 is also two groups of left and right symmetry, including: brake disc 9-1, wheel bearing 9-2, wheel body 9-3;

[0049] The pull rod handle 1 is on the top of the pull rod 6, the upper part of one end of the sliding device 3 is connected to the brake handle 2 and ...

Embodiment 2

[0073] 1. The drag box with brake anti-rotation function, including: pull rod handle 1, brake handle 2, sliding device 3, sliding device stop 5, pull rod 6, braking device 8, wheel assembly 9, central brake cable 10, Brake force equalizer bar 11, brake cable hole 11-1, side wing brake cable 12, support frame 13, pull rod bushing 15, wheel shaft rod 16;

[0074] It is characterized by:

[0075] The braking device 8 is two groups of left and right symmetry, and the braking device 8 includes: a brake cable connection seat 8-1, a return spring 8-2, a guide shaft support 8-3, a brake shoe pillar 8-4, and a pillar sleeve 8-5, brake cable guide shaft 8-6, brake cable stopper 8-7, brake shoe 8-8;

[0076] The wheel assembly 9 is also two groups of left and right symmetry, including: brake disc 9-1, wheel bearing 9-2, wheel body 9-3;

[0077] The pull rod handle 1 is on the top of the pull rod 6, the upper part of one end of the sliding device 3 is connected to the brake handle 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com